Environment-friendly industrial sand making equipment

An environmentally friendly and industrial technology, applied in the field of industrial automation equipment for sand making, can solve problems such as affecting the service life and crushing effect of the equipment, harming the health of workers, polluting the surrounding environment, etc., to avoid material weight gain, water saving and inhibition. Effect, the effect of not easy to collect dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

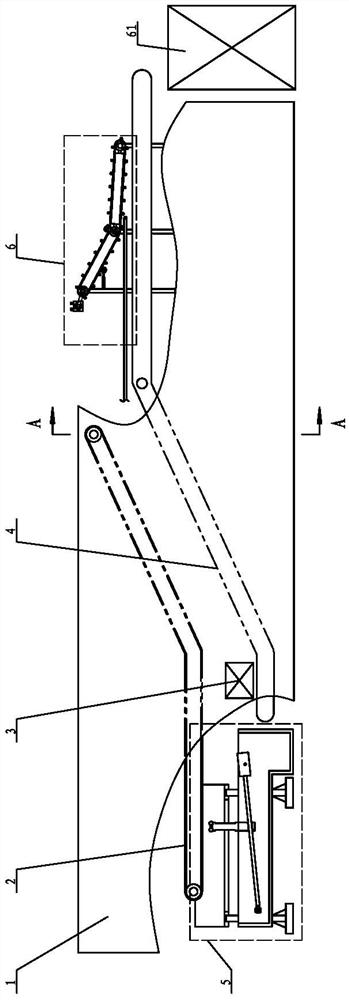

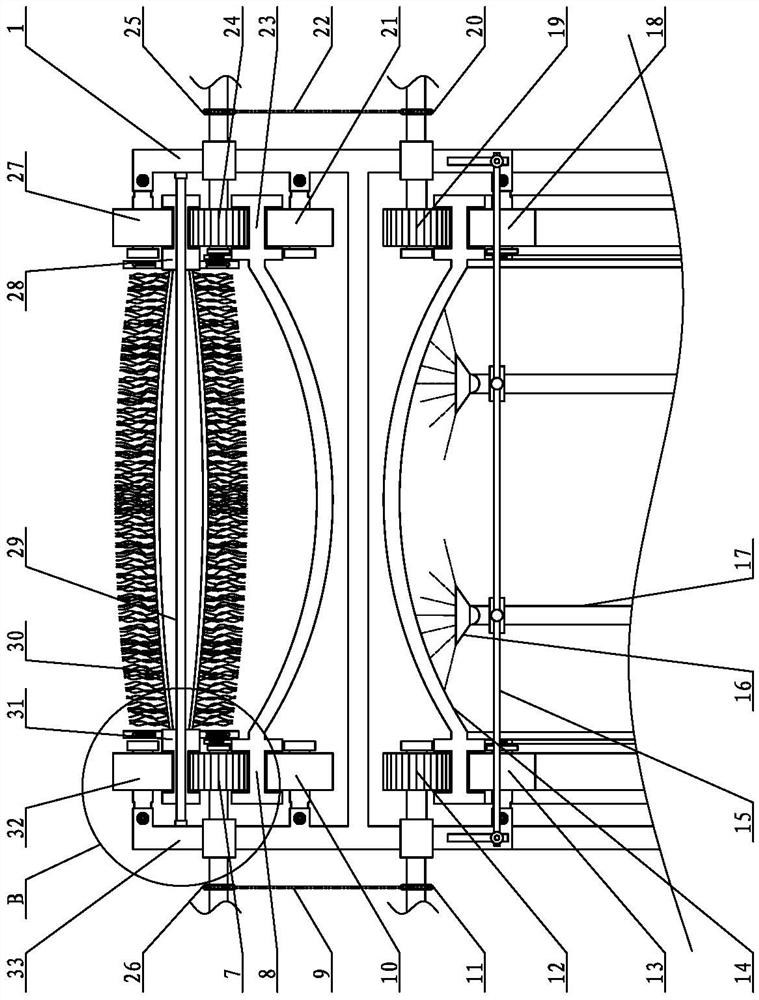

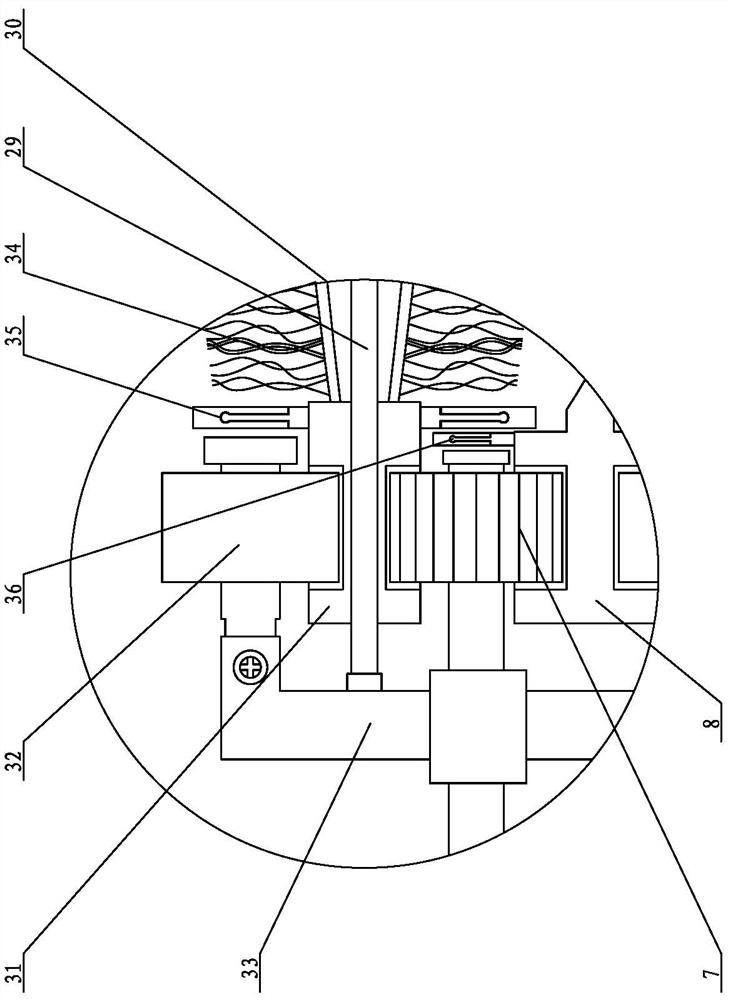

[0048] Such as figure 1 As shown, an environment-friendly industrial sand making equipment according to the present invention includes a main frame, a dust removal device, an iron removal device and a crushing device. The dust removal device and the crushing device are installed on the main frame, and the front end of the main frame is connected to The material storage and discharge device, the rear end of the main frame is connected with the crushing device; the material transmission device is installed on the main frame, the front end of the material transmission device is connected with the storage and discharge device, and the rear end of the material transmission device is connected with the crushing device. The material transmission device can The material in the storage and discharging device is conveyed and put into the crushi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com