Chassis frame

The technology of chassis frame and vertical plate is applied in the direction of vehicle components, load-bearing body structure, superstructure of trucks, etc., which can solve the problems of large impact and bumps, laborious and troublesome, overturning, and transportation difficulties for drivers and passengers, etc. Achieve the effect of improving work efficiency and resisting torsional deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

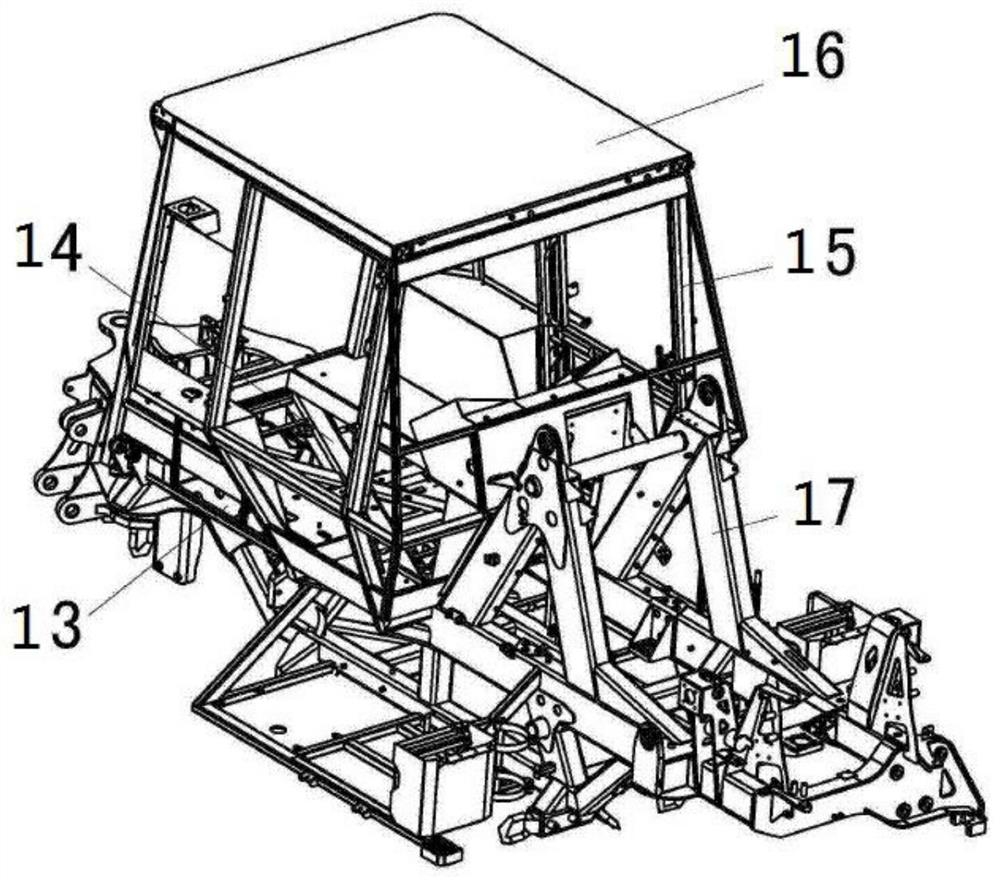

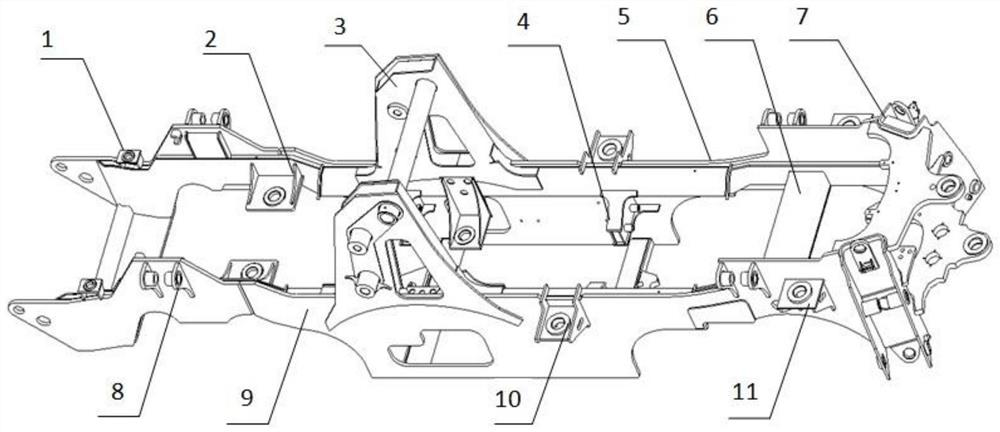

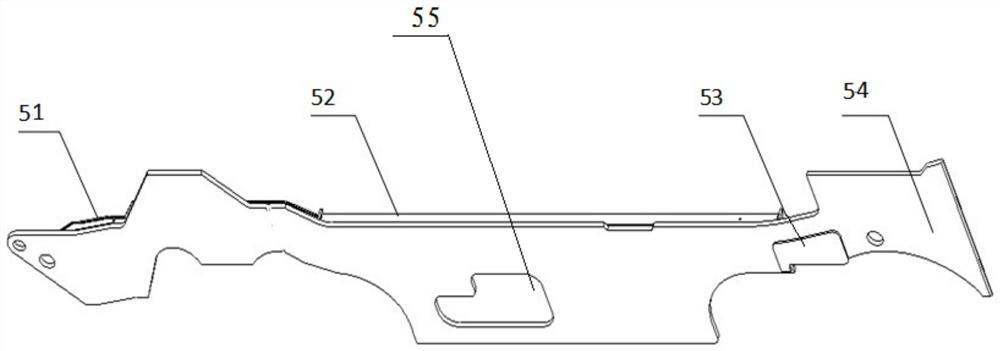

[0023] Such as figure 1 As shown, the present invention proposes a chassis frame, including a radiator seat 1, a power transmission seat 2, a loading device hinge seat 3, a thrust rod seat 4, a right vertical plate assembly 5, a beam 6, an excavating device hinge seat 7, a suspension Cylinder block 8, left vertical plate assembly 9, front cab seat 10, rear cab seat 11; the chassis frame of the present invention adopts a frame-type symmetrical structure, and each functional structure is compactly arranged, which can effectively improve working efficiency.

[0024] The radiator seat 1 is installed and supported by the radiator, and the front end of the vehicle frame is lowered by the design of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com