High-power heavy-load electric wheel driving motor lightening method and driving motor

A drive motor, high-power technology, applied in the direction of rolling resistance optimization, wheels, brakes, etc., can solve the problem of not integrating the reducer and braking device, etc., to reduce the axial structural size, reduce the overall structural size, shorten the axial The effect of structural dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

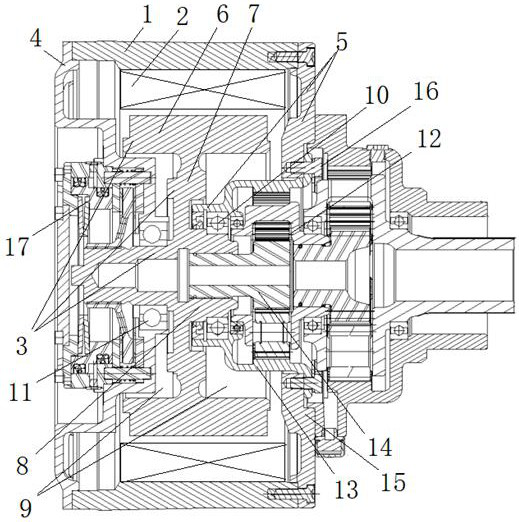

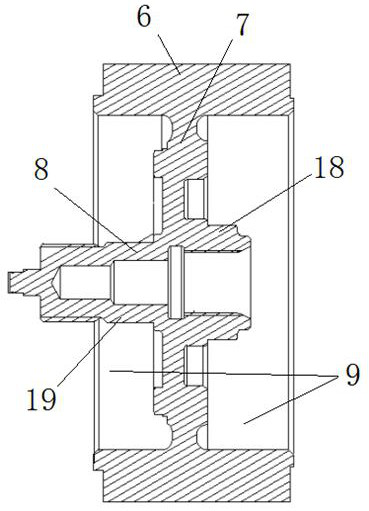

[0030] As can be seen from the accompanying drawings, the present invention relates to a high-power heavy-duty drive motor lightweight drive motor, including a drive motor casing 1, a drive motor stator 2, a drive motor rotor 3, a left end cover 4 and a right end cover 5, wherein the drive motor The stator 2 is embedded in the drive motor casing 1, and the drive motor rotor 3 is located in the drive motor stator 2, between the left end cover 4 and the right end cover 5; the drive motor rotor 3 includes a rotor 6, a support rib 7 and a mandrel 8; wherein, the rotor application part 6 and the mandrel 8 are connected through the support rib 7, and the support rib 7 is located in the middle of the rotor, forming a "king"-shaped drive motor rotor 3 section supported by the support rib 7 structure, so that the middle part of the rotor can be fully used to install other parts of the device; on the one hand, the weight of the motor rotor can be reduced, and the axial position connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com