Decorative sheet and manufacturing method

A technology of flakes and nano-films, applied in special decorative structures, decorative arts, etc., can solve the problems of lack of three-dimensional decorative effects, single decorative colors of decorative flakes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

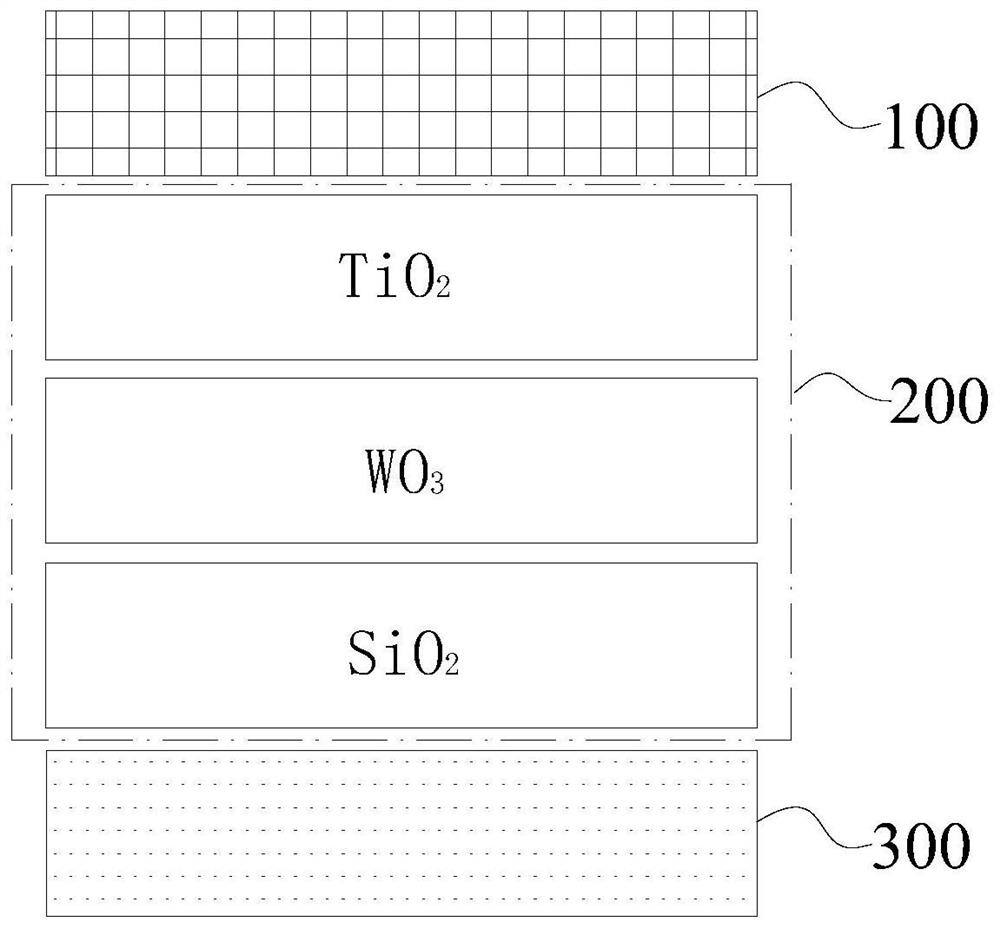

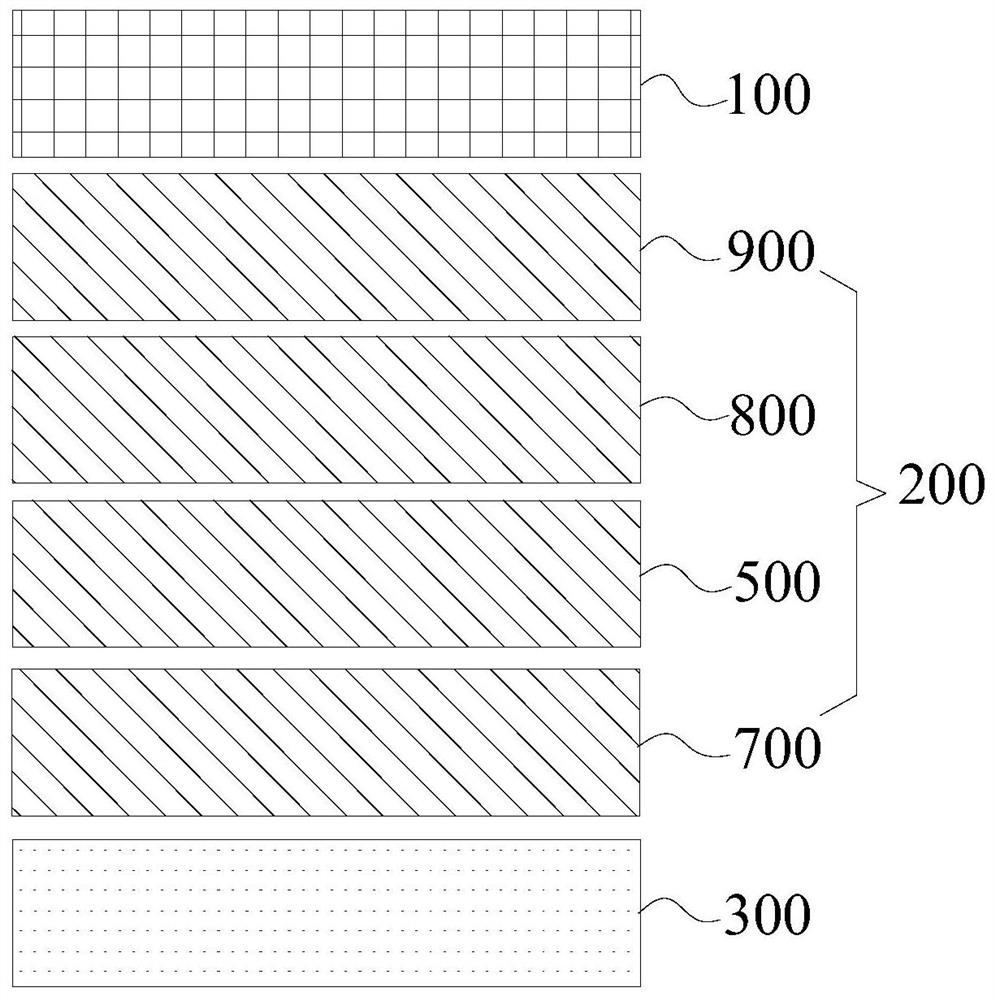

[0032] see figure 1 , shows the first decorative sheet in the first embodiment of the present invention, including a transparent substrate 300, an optical nanofilm 200 disposed on the transparent substrate 300, and an optical nanofilm disposed on the optical nanofilm 200 Ink layer 100, a surface of the transparent substrate 300 is provided with micro-nano textures (not shown), the optical nano-film 200 is plated on the micro-nano textures, and the optical nano-film 200 is a multilayer structure, the optical nano film 200 at least includes a color-changing layer 500 that can change the color of the decorative sheet, the thickness of the color-changing layer 500 is 150-600nm, the light after the action of the color-changing layer 500 passes through the micro-nano texture Afterwards, through the transparent substrate 300 , a three-dimensional effect is displayed.

[0033] In this application, the color changing layer 500 is WO 3 layer, using nano-WO 3 (tungsten oxide) as mater...

Embodiment 2

[0047] see Figure 5 , shows the method for manufacturing a decorative sheet in the second embodiment of the present invention, the method includes steps S1-step S4, specifically as follows:

[0048] S1. Obtain the transparent base material of the semi-finished product;

[0049] S2. Embossing micro-nano textures on a surface of the transparent substrate;

[0050] Firstly, the base material of transparent semi-finished products is processed by ordinary glass or transparent resin material, and then the required micro-nano texture is embossed on the upper surface of the base material through micro-nano imprinting technology. The micro-nano texture is relatively fine and the size It can reach about 0.075×0.035×0.015nm. When the visible light is irradiated on the surface of the substrate with micro-nano texture, the displacement and connection will occur when the reflected light is generated, so that the direction and angle of the reflected light will be displaced and connected t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com