Punching operation method for aircraft with camera

A technology of aircraft and camera, which is applied in the field of aircraft drilling operations, can solve the problems of adjusting the position of high-altitude operations and not providing them, and achieve the effect of improving synchronization and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the examples, but the present invention is not limited in any way, and any transformation or substitution made based on the teaching of the present invention belongs to the protection scope of the present invention.

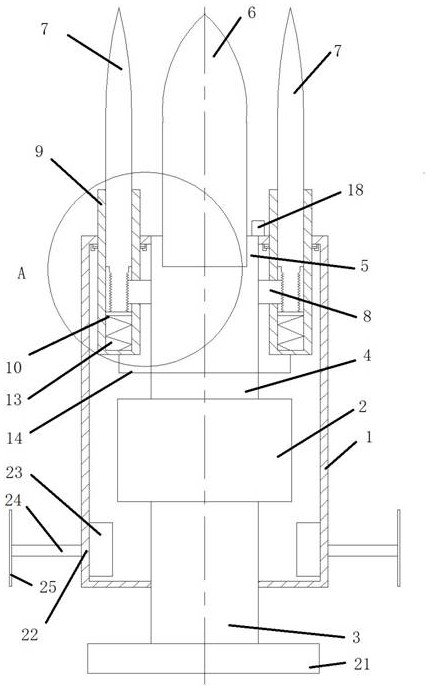

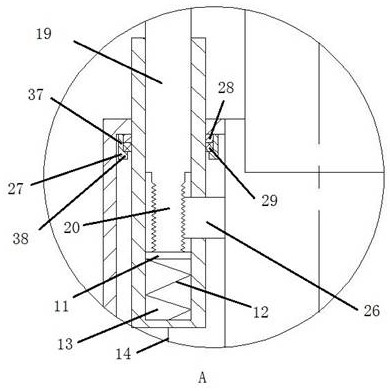

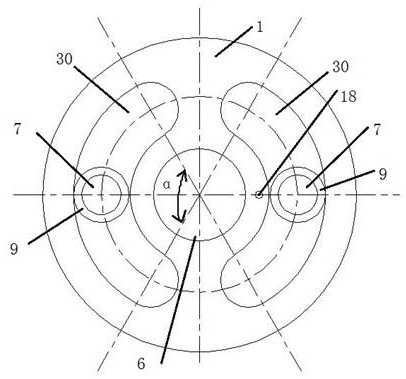

[0048] Such as Figure 1-6 As shown, the aircraft with an adjustable punching position with a camera of the present invention includes a housing 1, a drive motor 2, a rotating shaft 3, a drilling shaft 4, a drill bit 6, a fixing nail 7, a linkage mechanism 8, and a fixing nail sleeve 9. Push mechanism 10, camera 18, lifting blade 21, horizontal propulsion mechanism 22, ring chuck 27, upper ring 28, lower ring 29, rotating motor A33 and rotating motor B36, drive motor 2 is fixedly installed in the shell The inside of body 1, and the driving motor is a double-axis motor, the rotating shaft 3 is connected to the lower end of the driving motor 2, the rotating shaft 3 passes through the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com