Building aggregate regeneration device and use method thereof

A regeneration device and construction aggregate technology, applied in the direction of supply device, cement mixing device, clay preparation device, etc., can solve the problems that the strength of recycled concrete aggregate cannot be changed, and the production process is troublesome, so as to enhance the strength, reduce physical labor, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

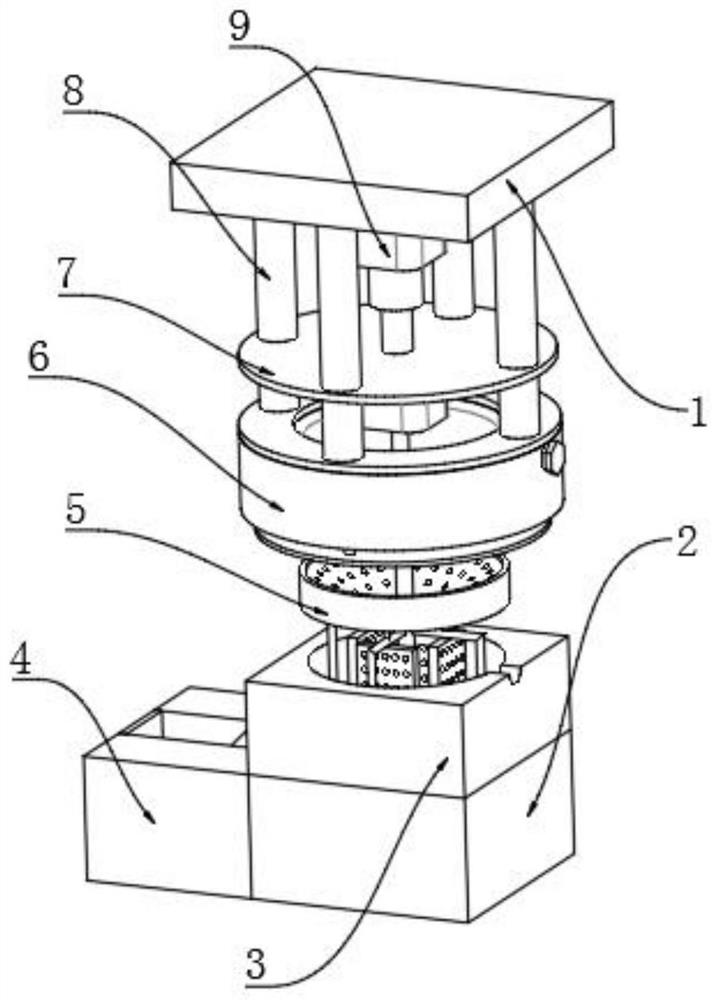

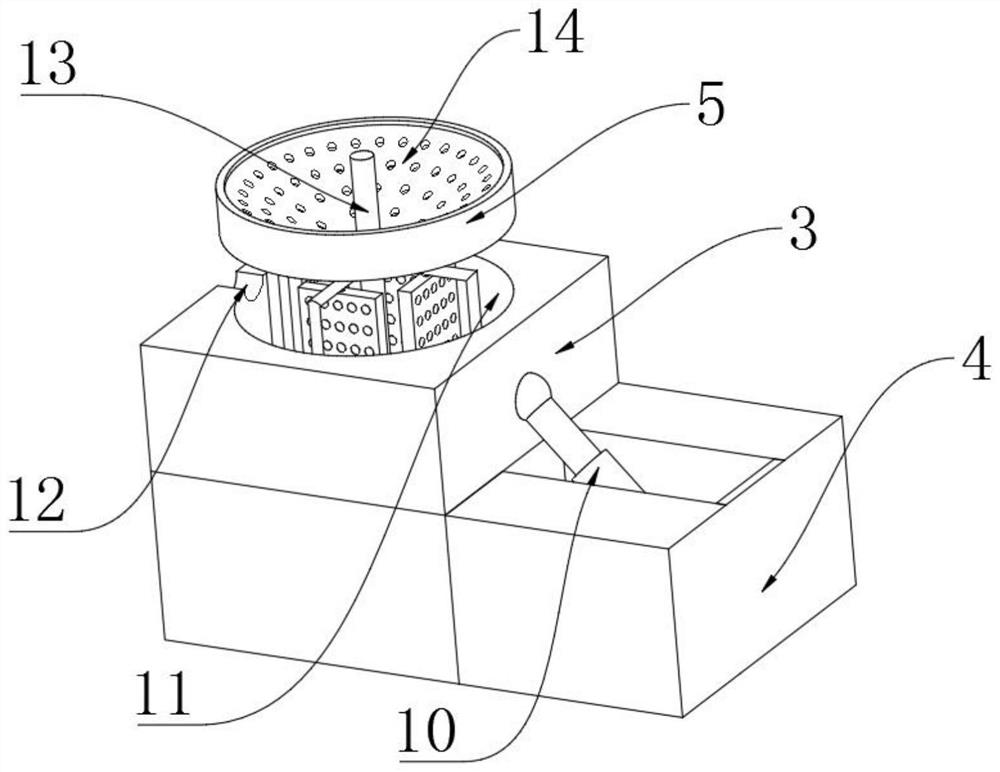

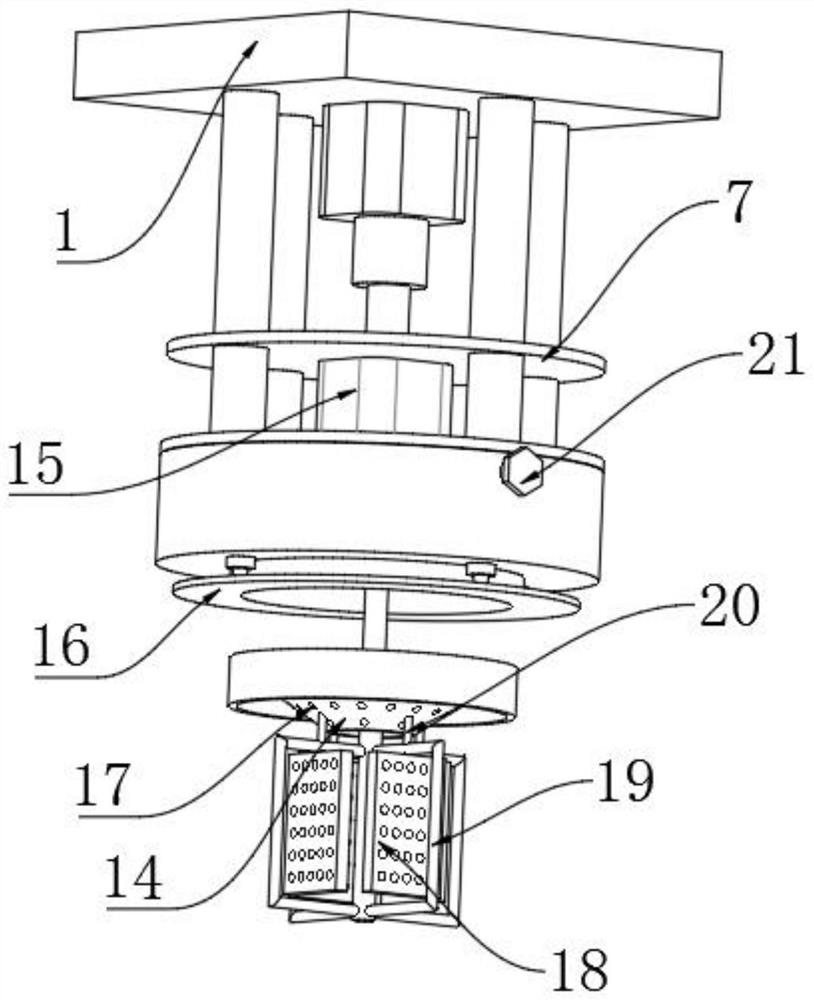

[0040] A construction aggregate recycling device, such as figure 1 , figure 2 , image 3 , Figure 7 As shown, it includes a top plate 1 and a supporting base 2; the outer wall of the bottom end of the top plate 1 is connected with an electric push rod 9 by bolts; the outer wall of the output shaft side of the electric push rod 9 is fixedly connected with a push plate 7 by screws; the bottom of the push plate 7 The outer wall of the end is connected with a drive motor 15 by bolts; the outer wall on one side of the output shaft of the drive motor 15 is connected with a rotating rod 13 through a coupling; 19 The inner wall of the top end is rotatably connected with a connecting rod 20; the outer wall of the bottom end of the connecting rod 20 is fixedly connected with a stirring plate 18 by screws; the inner wall of one side of the stirring plate 18 is processed with evenly distributed circular holes; the top plate 1 is provided with a control unit; Both the rod 9 and the dr...

Embodiment 2

[0047] A method for using a building aggregate regeneration device, such as Figure 8 shown, including the following steps:

[0048] S1: Introduce Portland cement, silica fume, quartz powder, fine aggregate and crushed concrete into the mixing hole 11, then introduce water containing water reducer into the water storage chamber 32, and put it into the fiber storage ring 31. Into the steel fiber;

[0049] S2: Operate the electric push rod 9, so that the stirring mechanism goes deep into the blending hole 11, and stirs the dry material for three minutes;

[0050] S3: Run the electric telescopic rod 29 to stop when all the steel fibers are exported, and at the same time make the electromagnetic layer 23 energized, and stir the wet material for two minutes;

[0051] S4: Run the electric telescopic rod 29 again until all the water containing the water reducing agent is exported, and stir the wet material for three minutes;

[0052] S5: Run the electric push rod 9 to retract the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com