Working method of hanging roller overturning vertical demolding pipe manufacturing equipment

A working method and technology of hanging rollers, applied in the direction of manufacturing tools, ceramic molding workshops, ceramic molding machines, etc., can solve the problems of high labor cost and mold cost, large energy loss, and high equipment manufacturing cost, and reduce auxiliary process time. , to achieve the effect of recycling and mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

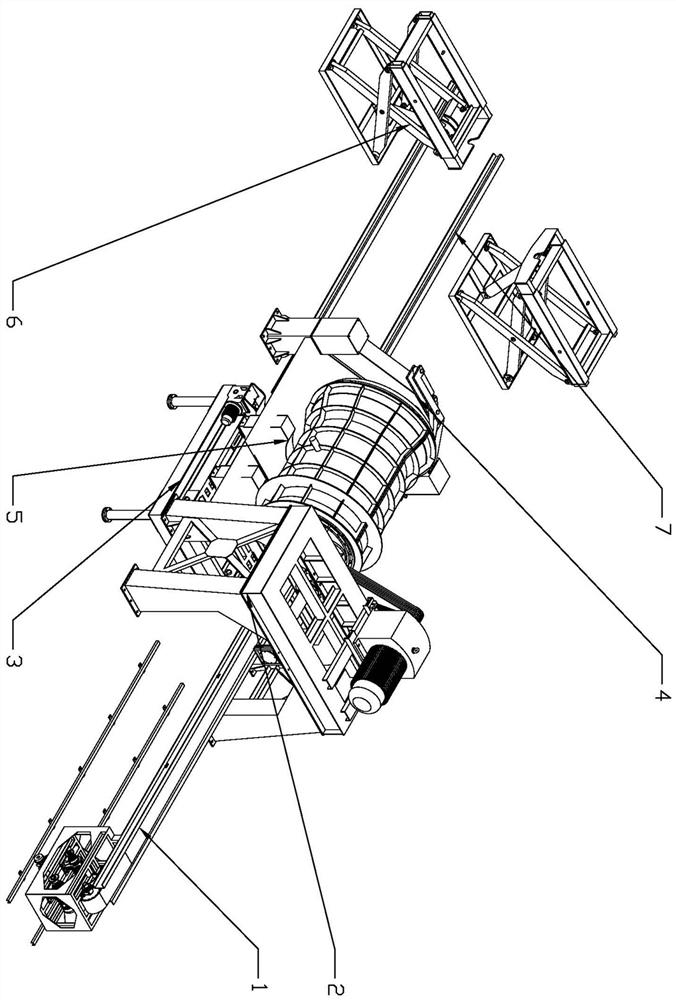

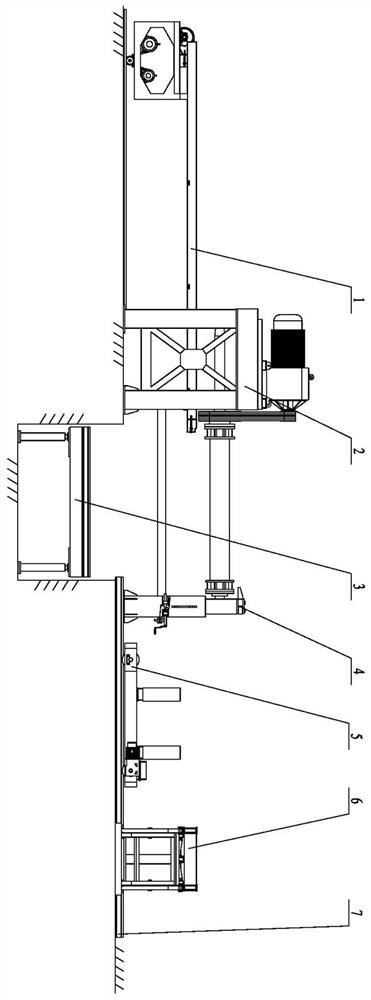

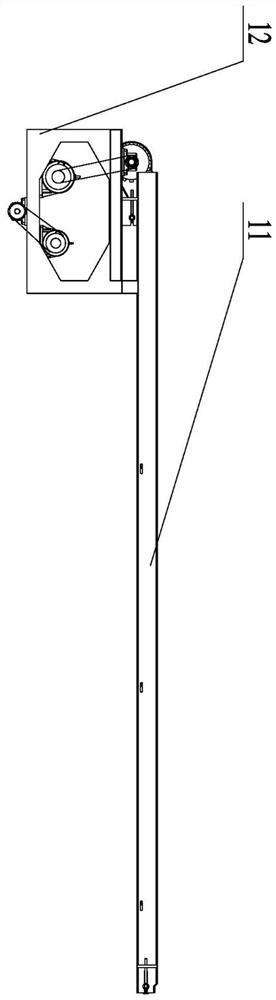

[0042] Such as Figure 1-12 As shown, in order to achieve the above purpose, the present invention provides a working method for the vertical roll-off pipe making equipment, which includes the equipment body, the equipment body includes the feeder (1), and the feeder (1) used The hanging roller machine (2), cooperate with the hanging roller machine (2) and install the lifting platform (3) in the pit, the exit of the hanging roller machine (2) is equipped with a positioning fork (4), and the positioning dial A ground guide rail (7) is installed on the ground at the rear end of the fork (4), and a transport trolley (5) is correspondingly arranged on the ground guide rail (7), and a lifting turning machine (6) is installed on both sides of the ground guide rail (7); The equipment body is also equipped with hanging roller molds, and each hanging roller mold is equipped with a bottom tray (10); the hanging roller machine (2) includes a hanging roller frame (21), a driving system (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com