Cone Roller Cylinder Sizing Equipment

A tapered roller and roller technology, applied in the field of tapered roller shaping equipment, can solve the problems of uneven surface of the tapered roller, achieve the effect of reducing unevenness, reducing the possibility of deflection and slipping, and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

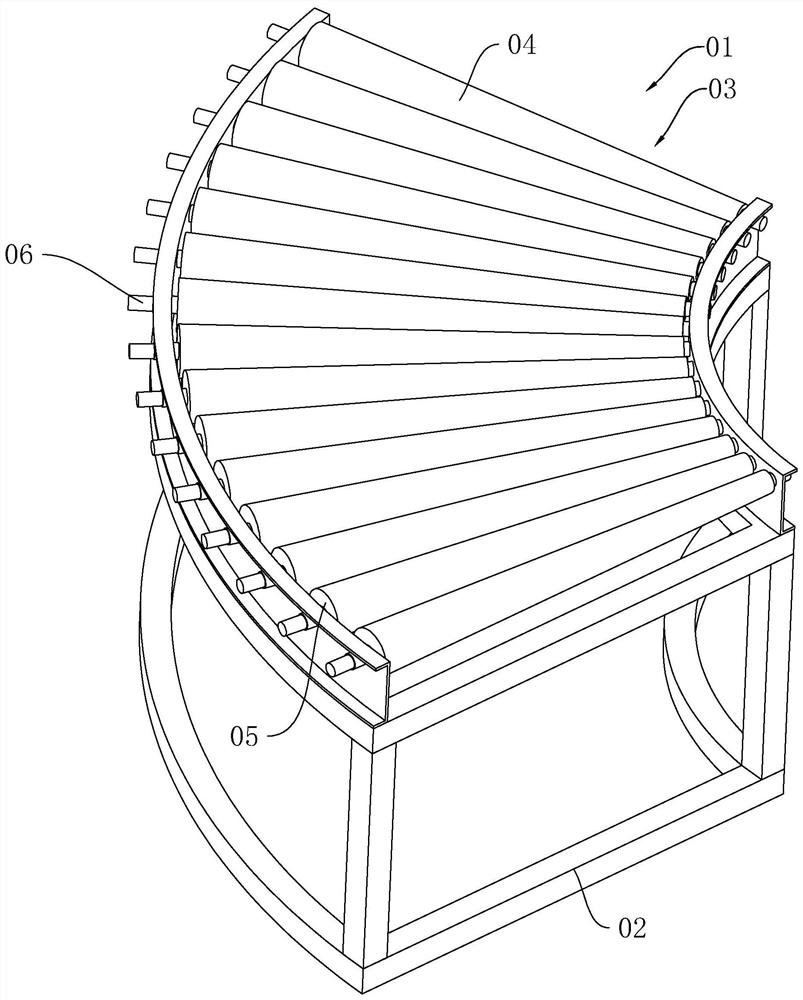

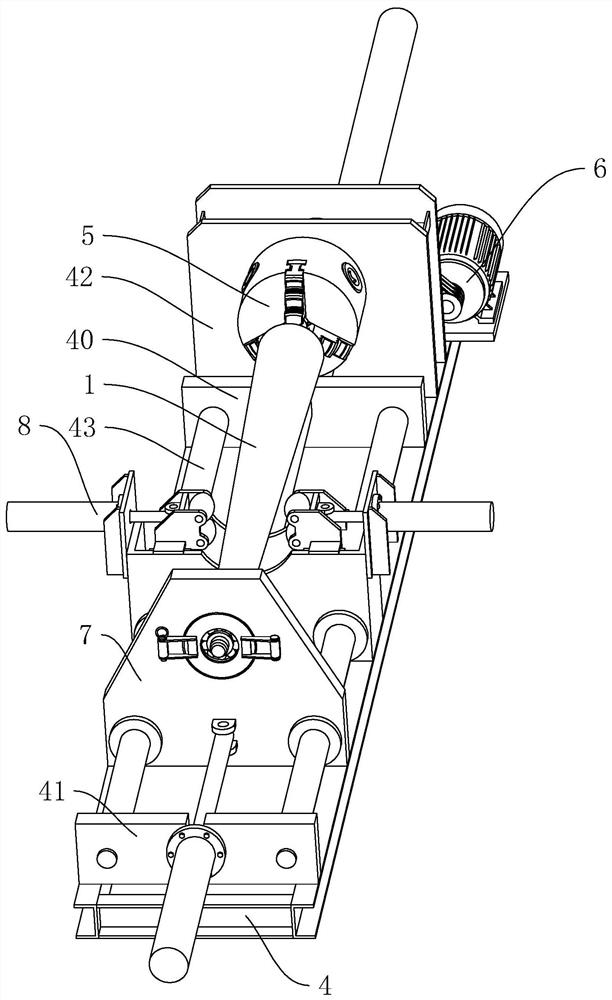

[0043] The following is attached Figure 1-7 The application is described in further detail.

[0044] The embodiment of the present application discloses a mold for forming a tapered roller.

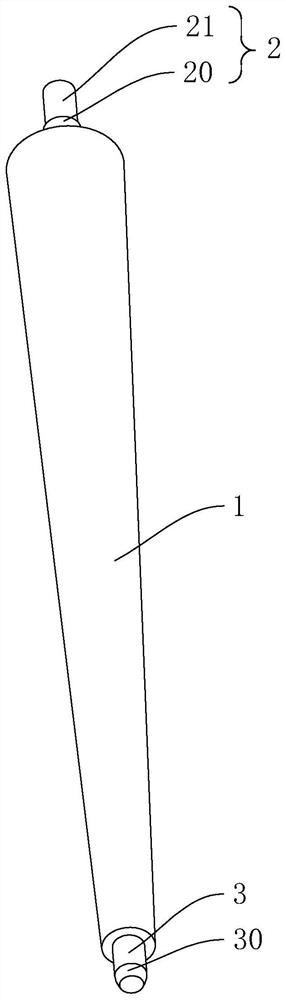

[0045] refer to figure 1 and figure 2 , a mold for forming a tapered roller, including a tapered roller 1 for inserting a tapered roller 04, the surface of the tapered roller 1 is smooth, and the outer wall of the tapered roller 1 is bonded to the inner wall of the tapered roller 04 The larger end of the tapered roller 1 is provided with a support rod 2 for installing the tapered roller 1, the support rod 2 includes a relief post 20 connected with the tapered roller 1 and a mounting post 21 connected with the relief post 20, and the installation The diameter of the pillar 21 is smaller than the diameter of the relief pillar 20 .

[0046] refer to figure 1 and figure 2 The smaller end of the tapered roller 1 is provided with a support column 3 for fixing the tapered roller 1, the ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com