Module combined dust remover

A dust collector and combined technology, applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve the problems of large space, cracks in the center hole of the valve plate, inconvenience, etc., and reduce labor intensity and difficulty , Guarantee welding quality and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

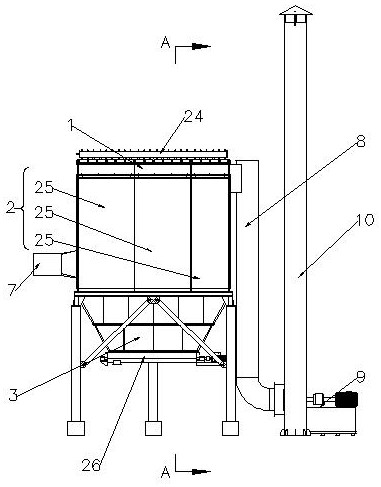

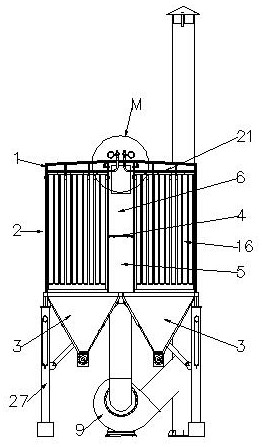

[0037] like Figure 1-Figure 8 Commonly shown, the present invention provides a modular combined type dust collector, the dust collector is a double-row structure, the double-row structure is a symmetrical two-row dust collector unit, a row of several dust removal units is arranged in the dust collector unit, and the number of each dust removal unit It is at least one; the dust collector unit includes a clean air chamber 1 at the top, a dust removal box 2 in the middle and an ash hopper 3 at the bottom; both the clean air chamber 1 and the dust removal box 2 are modular and assembled structures.

[0038] The bottom of the clean air chamber 1 is fixedly connected with the top of the dust removal box 2 by bolts, and the bottom of the dust removal box 2 is fixedly connected with the top of the ash hopper 3 by bolts.

[0039] A common air duct is provided on the opposite side of the double-row structure dust collector unit, and the two ends and the top of the air duct are sealed b...

Embodiment 2

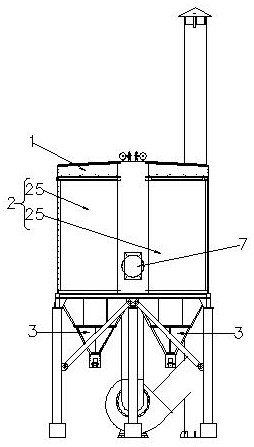

[0066] The invention provides a modular combined dust collector, the dust collector has a single-row structure, and the single-row structure is a single-row dust collector unit;

[0067] The single-row structure dust collector can be equipped with an inlet pipe 7 and an exhaust pipe 8 separately, and the inlet pipe 7 enters from the opening of the ash hopper 3 .

[0068] The number of header pipes (24) of the single-row structure dust collector is one, the header pipes (24) and pulse valves (23) are arranged in a single row, the header pipes (24), pulse valves (23) and pulse valves (23) The blowpipe (21) setting mode is the same as that of the double row structure dust collector.

[0069] The bottom of the dust removal box (2) of the single-row structure dust collector is provided with a single-row ash hopper (3), and the width of the ash hopper (3) is larger than the width of the dust removal box (2).

[0070] The concrete dedusting process of the present embodiment:

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com