Preparation process of millimeter wave antenna-radio frequency integrated module

A millimeter-wave antenna and radio frequency integration technology, which is applied in the direction of printed circuit manufacturing, electrical components assembly printed circuits, electrical components, etc., to achieve the effect of improving efficiency, improving production efficiency, and shortening the number of processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

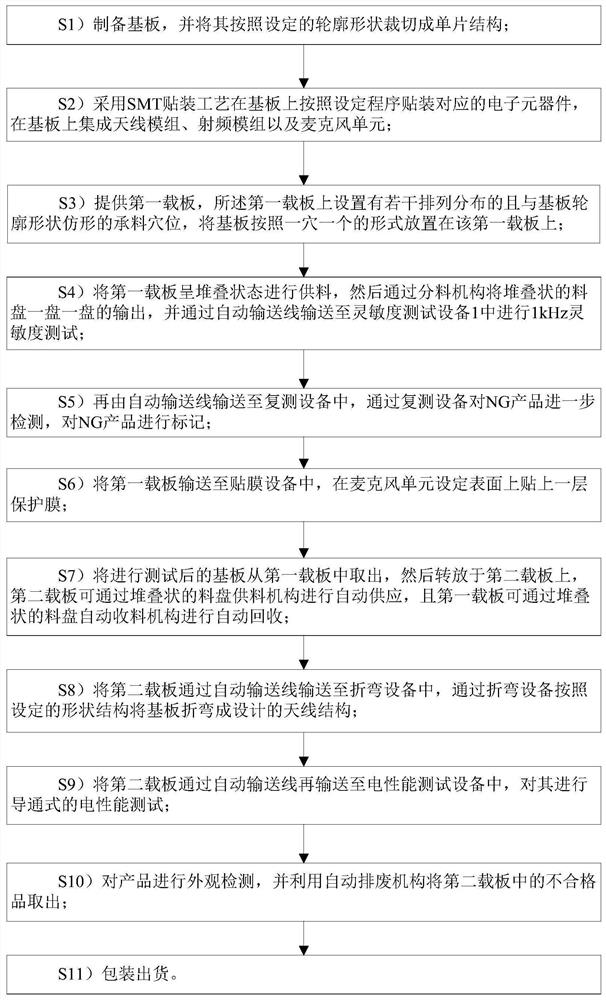

[0027] Please refer to figure 1 , this embodiment is a manufacturing process of a millimeter wave antenna and radio frequency integrated module, which includes the following steps:

[0028] S1) Prepare the substrate, and cut it into a monolithic structure according to the set contour shape;

[0029] S2) Mount the corresponding electronic components on the substrate according to the set procedure by using the SMT mounting process, and integrate the antenna module, radio frequency module and microphone unit on the substrate;

[0030] S3) A first carrier is provided, the first carrier is provided with a number of material-carrying holes that are arranged and distributed and conform to the outline of the substrate, and the substrate is placed on the first carrier in the form of one hole superior;

[0031] S4) Feed the first carrier boards in a stacked state, and then output the stacked trays one by one through the feeding mechanism, and transport them to the sensitivity testing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com