Solid waste treatment furnace and solid waste treatment method

A technology of solid waste and treatment method, applied in the field of solid waste treatment furnace and treatment, can solve the problems of high fly ash content, easy slag blocking at the slag discharge port, and difficulty in smooth liquid slag discharge at the slag discharge port, thereby reducing the Fly ash content, the effect of reducing the amount of nitrogen oxides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0104] 1. Solid waste treatment furnace

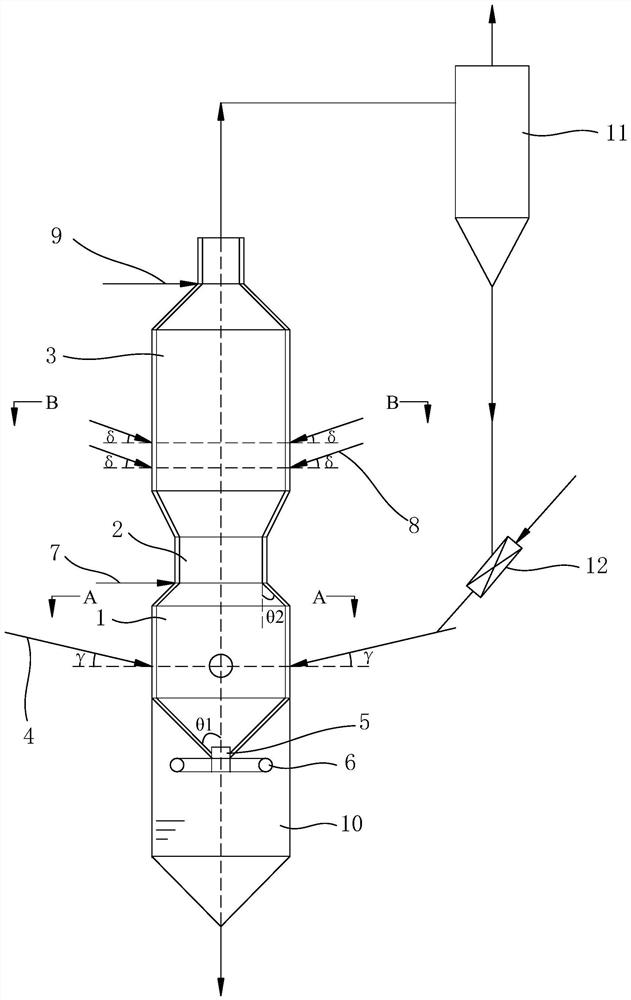

[0105] Such as figure 1 The shown solid waste treatment furnace has a furnace body surrounded by water-cooled walls. The furnace body includes a melting chamber 1, a necking section 2, and a combustion chamber 3 from bottom to top, and is arranged above the combustion chamber 3. An outlet pipe communicating with the combustion chamber 3;

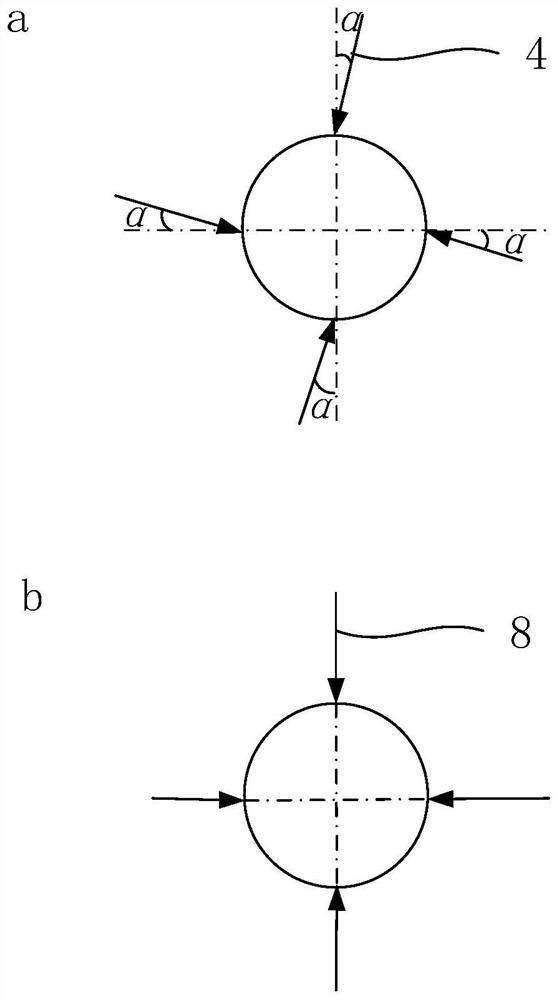

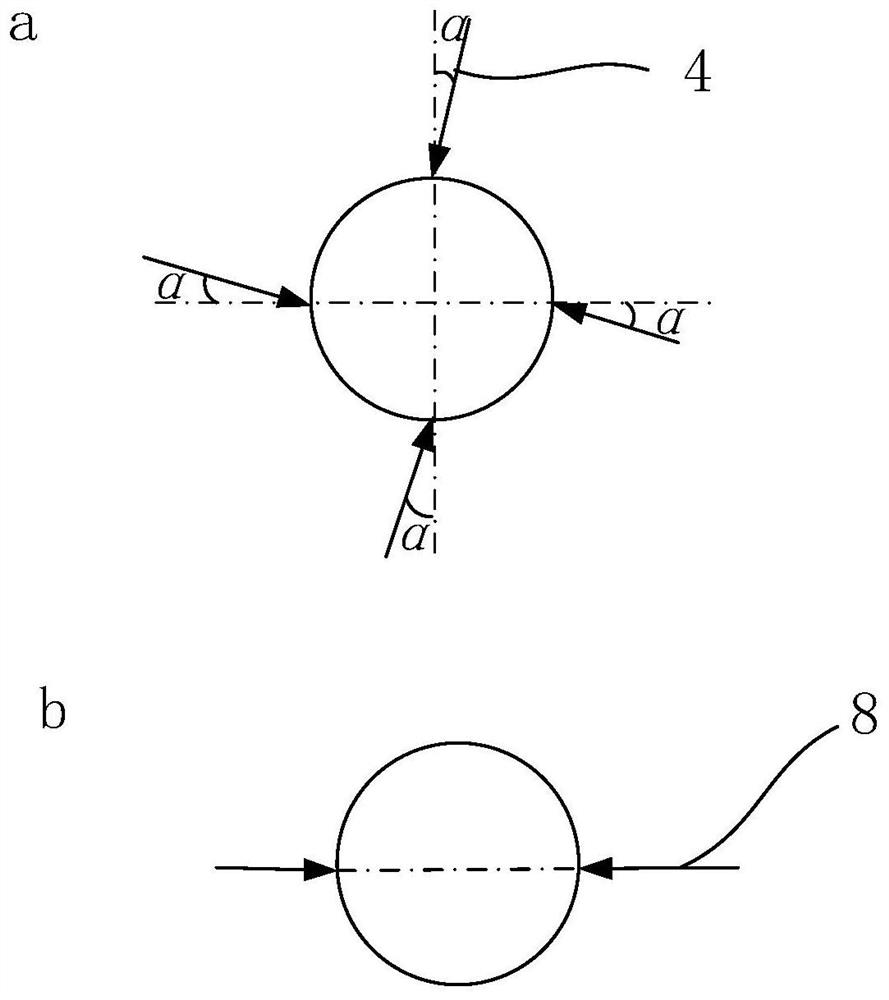

[0106] The straight section of the melting chamber 1 is provided with a first nozzle 4, the angle between the axis of the first nozzle 4 and the radial direction of the furnace body is α, "the intersection point of the axis of the first nozzle 4 and the inner wall surface of the straight section of the melting chamber 1 The vertical distance between " and the bottom surface of the straight section of melting chamber 1 is h1; the ratio of the length of the straight section of melting chamber 1 to the inner diameter of the straight section of melting chamber 1 is x1; the bottom of the lower cone secti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com