Method for improving whiteness of polyvinyl alcohol

A technology of polyvinyl alcohol whiteness and polyvinyl alcohol, applied in the field of polyvinyl alcohol preparation technology, can solve the problems of product yellowing, high drying efficiency, low volatile content, etc., achieve high whiteness, improve production efficiency, and accelerate removal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

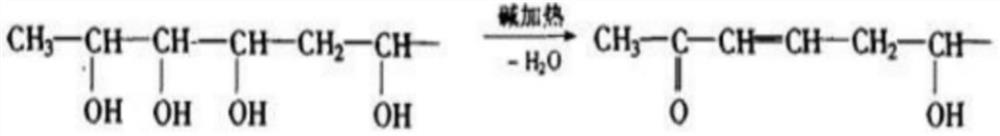

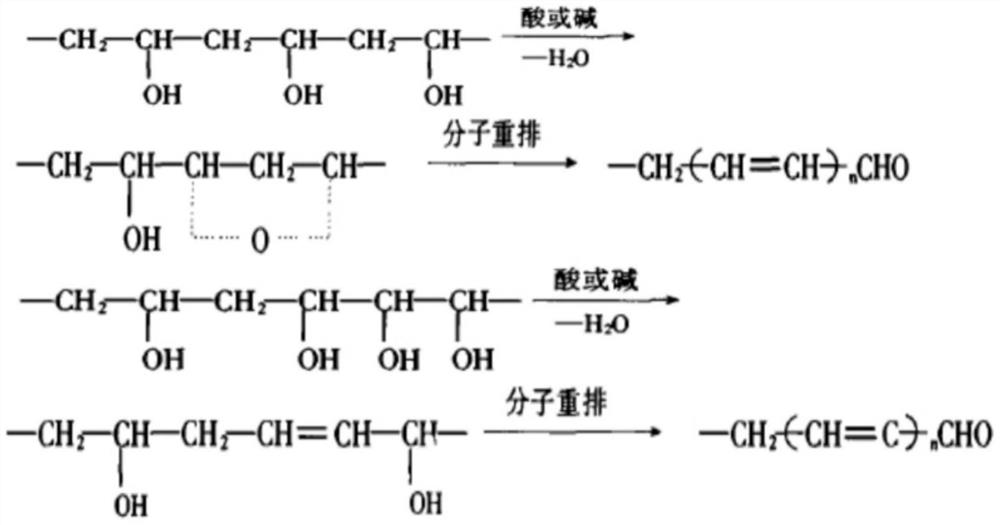

Problems solved by technology

Method used

Image

Examples

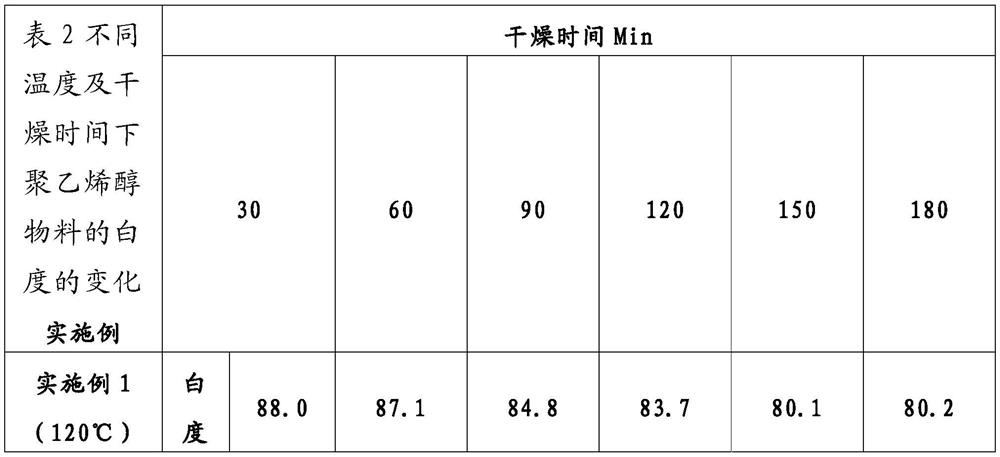

Embodiment 1

[0106] Embodiment 1: Get six parts of polyvinyl alcohol semi-finished product 8~10g of degree of alcoholysis ≥ 99.0%, put into 6 weighing bottles respectively, and put it into the oven that temperature is 120 ℃ and dry it, Take out a weighing bottle every 5Min and analyze the samples in it. After analysis and detection, with the prolongation of drying time, the whiteness of the sample gradually decreased, and the color gradually deepened. The sample began to change color after 2 hours of drying, and the whiteness of the sample with a drying time of 3 hours was 80.2%.

Embodiment 2

[0107] Embodiment 2: Get six parts of polyvinyl alcohol semi-finished product 8~10g of degree of alcoholysis ≥ 99.0%, put into 6 weighing bottles respectively, and put it into the oven that temperature is 160 ℃ and dry it, Take out a weighing bottle every 5Min and analyze the samples in it. After analysis and detection, with the prolongation of the drying time, the whiteness of the sample rapidly and gradually decreased, and the color gradually deepened. The sample began to change color when the drying time was 10 minutes, and the whiteness of the sample with a drying time of 30 minutes was 65.0%. It can be seen that the drying temperature is too high, which is not conducive to maintaining the whiteness of polyvinyl alcohol products.

Embodiment 3

[0108] Embodiment 3: Get six parts of polyvinyl alcohol semi-finished product 8~10g of degree of alcoholysis ≥ 99.0%, put into 6 weighing bottles respectively, and put it into the oven that temperature is 170 ℃ and dry it, Take out a weighing bottle every 5Min and analyze the samples in it. After analysis and detection, with the prolongation of drying time, the whiteness of the sample decreased rapidly, and the color gradually deepened. The sample began to change color when it was dried for 5 minutes, and the whiteness of the sample with a drying time of 30 minutes was 50.0%. It can be seen that the drying temperature is too high, which is not conducive to maintaining the whiteness of polyvinyl alcohol products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| volatile matter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com