Moxa floss rolling rod strip forming device capable of automatically dispensing moxa paper

A strip-forming device and self-spotting technology, which can be used in devices for coating liquid on the surface, coiling strips, and instruments for heating/cooling reflection points, etc. problem, to achieve high efficiency and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

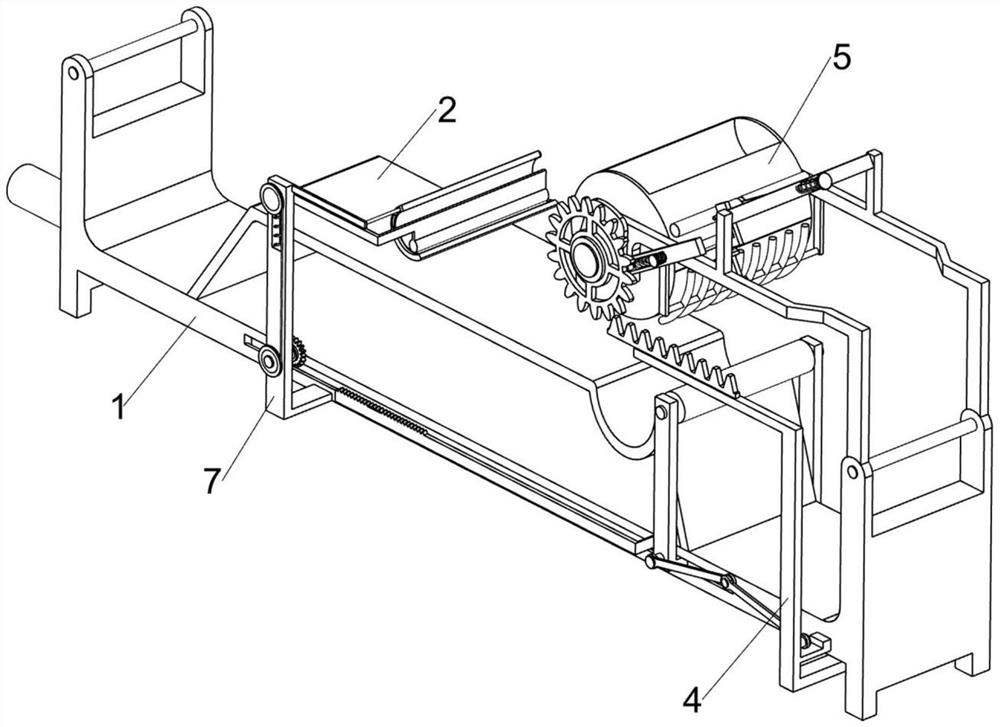

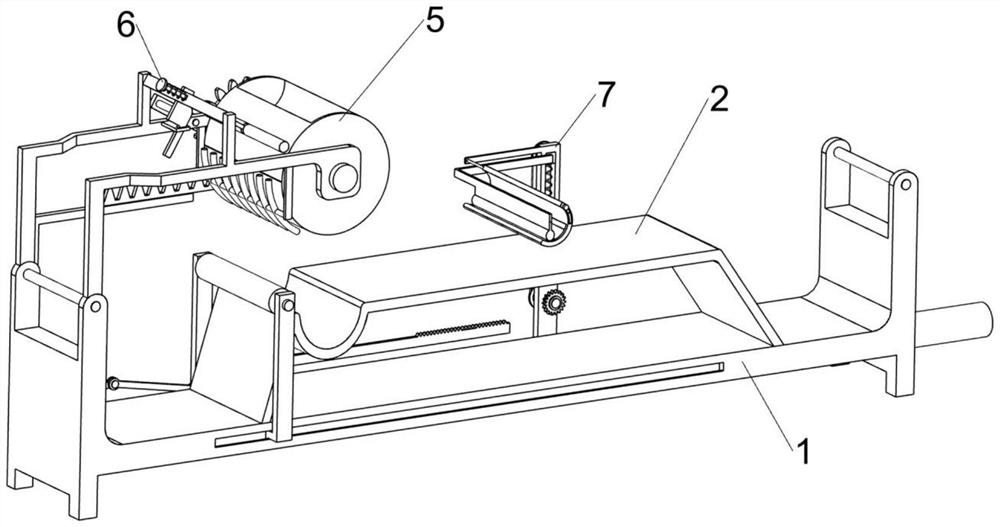

[0026] A moxa roll rod forming device capable of self-dispensing moxa paper, such as Figure 1-8 As shown, it includes a base 1, a winding table 2, a drum 3, a winding advancing assembly 4, a moxa rotating assembly 5 and a moxa compacting assembly 6, and the winding table 2 is installed on the top of the base 1, and the winding table 2 is used for For placing moxa paper, rollers 3 are symmetrically fixed on both sides of the upper part of the base 1, and the rollers 3 are used to connect the plastic film. The moxa paper of moxa is rolled into a moxa stick, the moxa rotating assembly 5 is arranged on the base 1, and the moxa compacting assembly 6 is arranged on the moxa rotating assembly 5, and the moxa rotating assembly 5 and the moxa are compacted. The mutual cooperation of components 6 can compact the moxa.

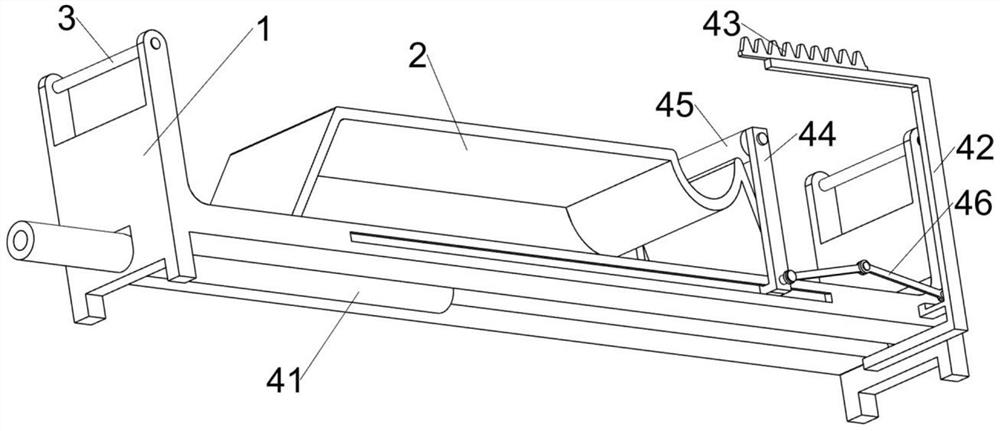

[0027] The coil advance assembly 4 includes an electric push rod 41, a fixed rod 42, a power rack 43, a slide bar 44, a coil roll 45 and a connecting rod 46. The elect...

Embodiment 2

[0032] On the basis of Example 1, such as Figure 7-8 As shown, the moxa paper dispensing assembly 7 is also included. The moxa paper dispensing assembly 7 is arranged on the base 1. The moxa paper dispensing assembly 7 is used to apply glue to the moxa paper. The moxa paper dispensing assembly 7 includes a fixed Rack 71, fixed slot bar 72, movable bar 73, overrunning clutch two 74, rotating gear 75, cable disc one 76, support spring 77, lifting block 78, cable disc two 79, steel wire deep cable 710 and glue dispensing rod 711, The fixed rack 71 is affixed to one side of the bottom of one of the sliding rods 44 away from the support frame 51. The fixed rack 71 is used to drive the rotating gear 75 to rotate. The type is located at the lower part of the fixed groove rod 72, the movable rod 73 is used to drive the cable reel 1 76 to rotate forward, the overrunning clutch 2 74 is fixedly connected to one side of the movable rod 73, the overrunning clutch 2 74 is used to drive the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com