Overturning type discharging hopper capable of imitating manual material pouring

A flip-type, hopper technology, used in emptying containers, loading/unloading, bottle filling, etc., can solve problems such as substandard products, drug card clogging, capsule or tablet damage, etc., to achieve a simple structure and avoid manual contact. , The effect of preventing moisture failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

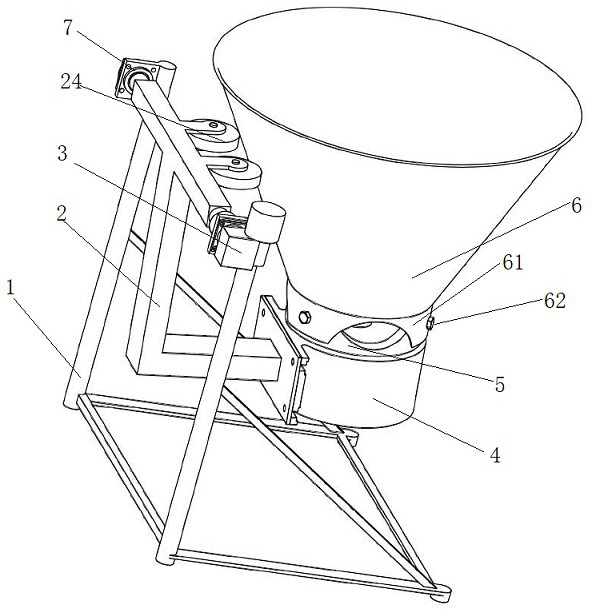

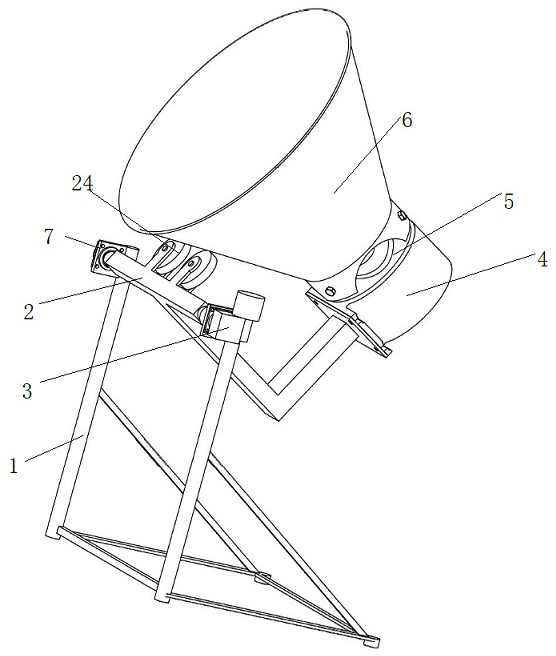

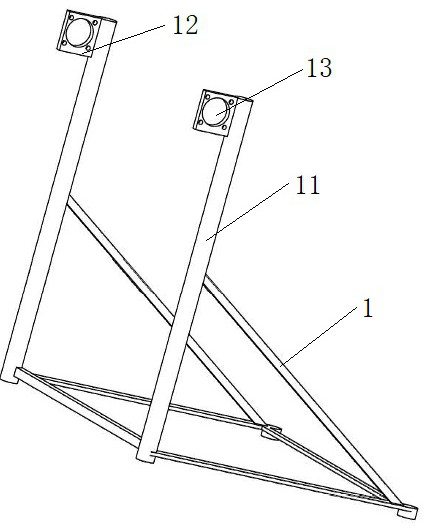

[0035] Such as Figure 1~2 As shown, a flip-type discharge hopper imitating manual dumping disclosed in this embodiment includes a bracket 1, a swing frame 2, a swing motor 3, a rotating motor 4, a hopper seat 5 and a hopper 6, and the swing frame is installed on On the bracket, the swing motor is fixed on the bracket and connected to one end of the swing frame, driving the swing frame to rotate axially along the bracket, the rotating motor is installed on the free end of the swing frame, the hopper seat is fixed on the shaft of the rotating motor, and the hopper is installed On the hopper seat, the swing motor dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com