Medical pipe machining device and machining method thereof

A processing device and medical tube technology, applied in the field of tube processing, to achieve rapid and uniform arcing and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

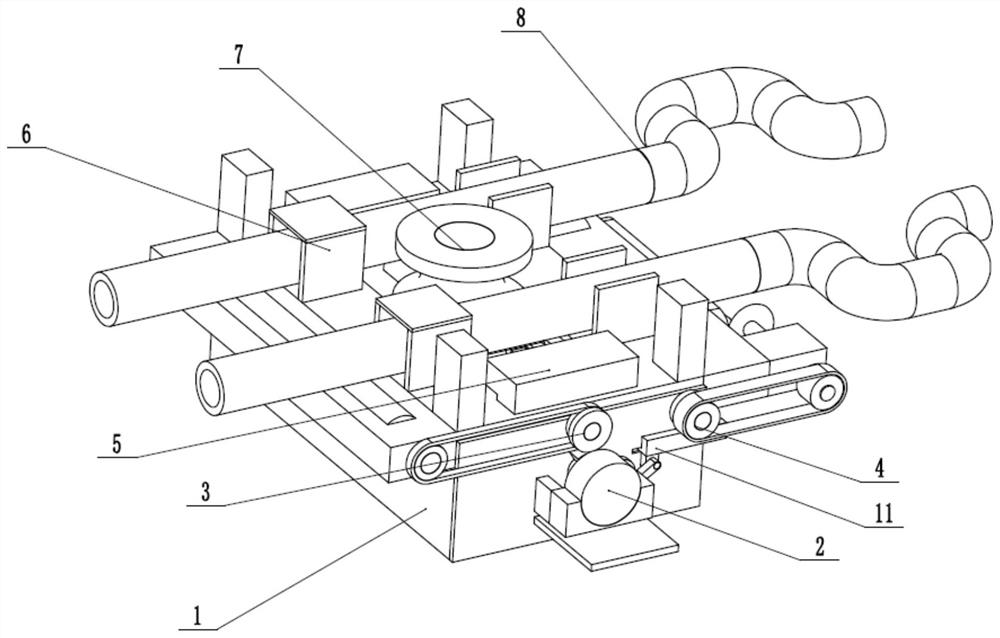

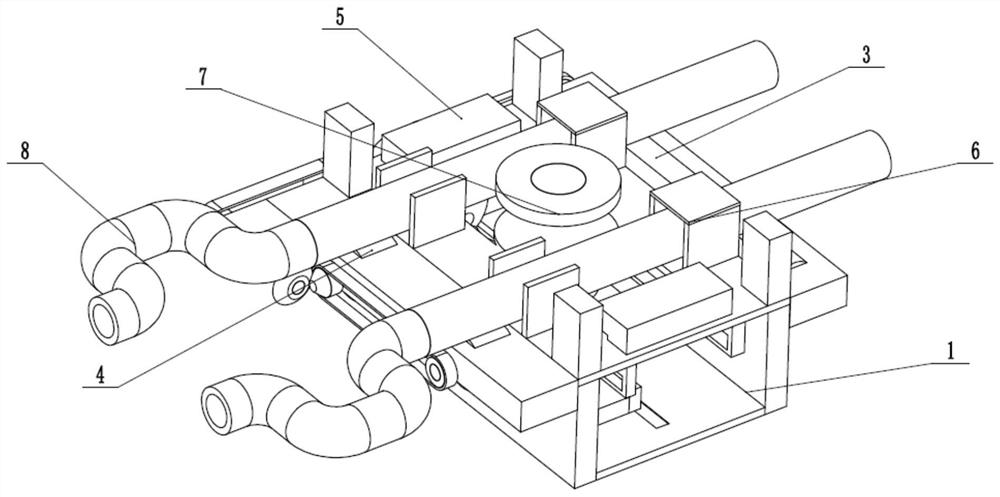

[0030] Such as Figure 1 to Figure 8 As shown, a medical tube processing device includes a tube arc processing frame 1, a combined driver 2, an intermittent drive adder 3, an intermittent drive steering gear 4, two arc-shaped top seats 5, four limit frames 6, an arc Extruder 7, two adding pipes 8 and reciprocating drive diverter 11, the combined driver 2 is rotatably connected on the pipe arc processing frame 1, the combined driver 2 intermittently drives the intermittent drive adder 3 and the reciprocating drive variable The reciprocator 11, the intermittent drive adder 3 and the intermittent drive diverter 4 are respectively rotatably connected to the two ends of the pipe arc processing frame 1, the reciprocating drive diverter 11 intermittently drives the intermittent drive diverter 4 to reciprocate, and the two arc tops Seat 5 is uniformly and fixedly connected to pipe arc processing frame 1, and four limit frames 6 are evenly and fixedly connected to pipe arc processing f...

specific Embodiment approach 2

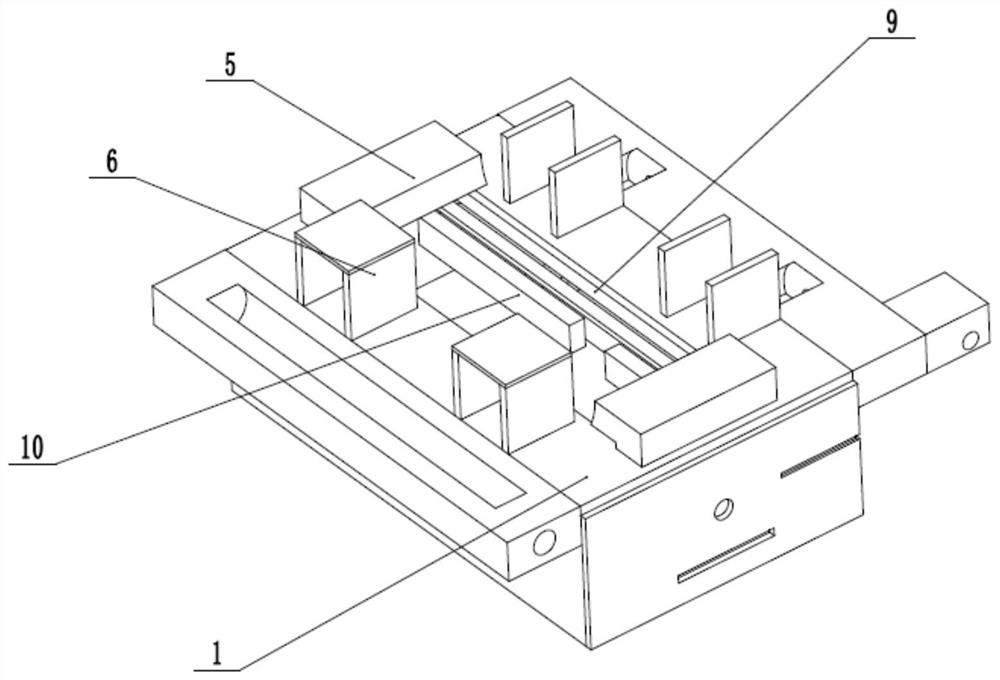

[0032] Such as Figure 1 to Figure 8 As shown, this embodiment further explains the first embodiment, the pipe arc processing frame 1 is provided with a central slot, the pipe arc processing frame 1 is fixedly connected to the slide rail 9, and the two fixed racks 10 are fixedly connected In the pipe arc processing frame 1.

specific Embodiment approach 3

[0034] Such as Figure 1 to Figure 8 As shown, this embodiment further explains the second embodiment. The combined driver 2 is fixedly connected to the pipe arc processing frame 1 through a point-release fixing seat, and the transmission shaft of the combined driver 2 is connected to the pipe arc processing frame in rotation. 1, the transmission shaft of the combination driver 2 is fixedly connected with an intermittent drive gear 12, and the intermittent drive gear 12 is intermittently meshed to drive the intermittent drive adder 3 and the reciprocating drive commutator 11. Combined driver 2 is connected to electricity and drives intermittent drive adder 3 and add rubber roller 13 to rotate by connecting intermittent drive gear 12, adding pipe 8 evenly in pipe arc processing frame 1, and then stops.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com