Clamp for finish machining of gearbox shell and clamping method

A gearbox and housing technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problem that the tightening fixture cannot guarantee the processing accuracy, etc., and achieve the effect of good consistency, not easy to deform, and ensure rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

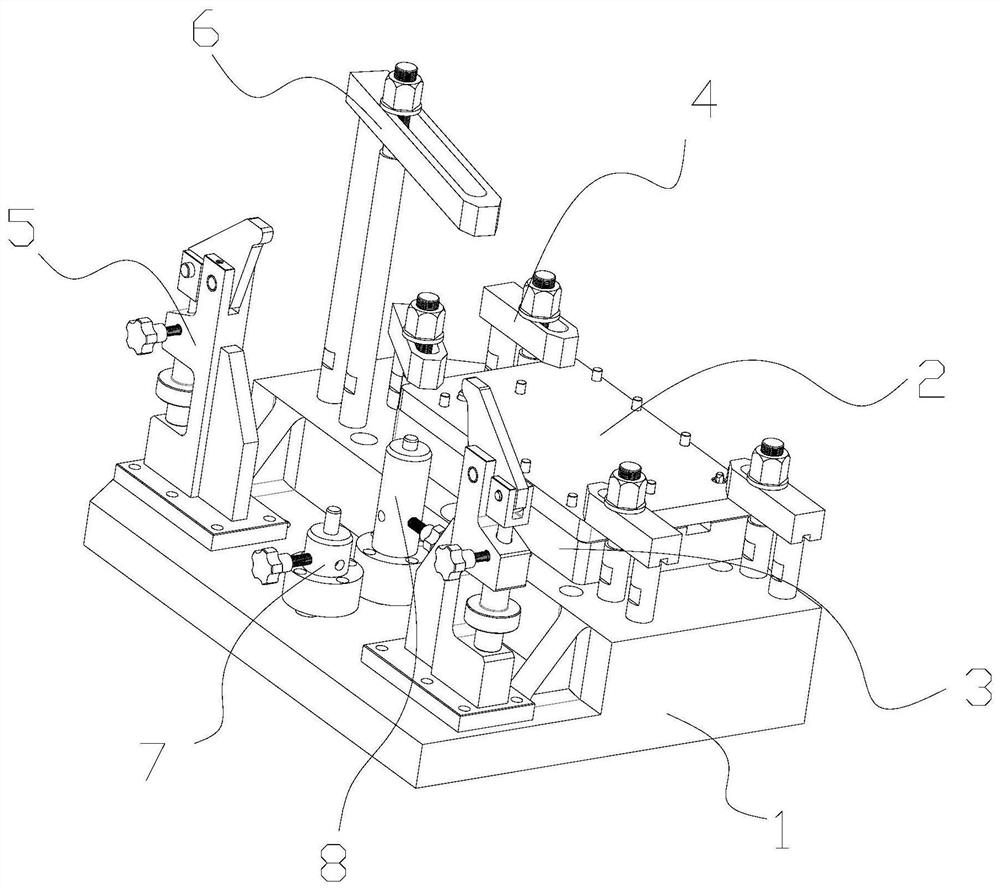

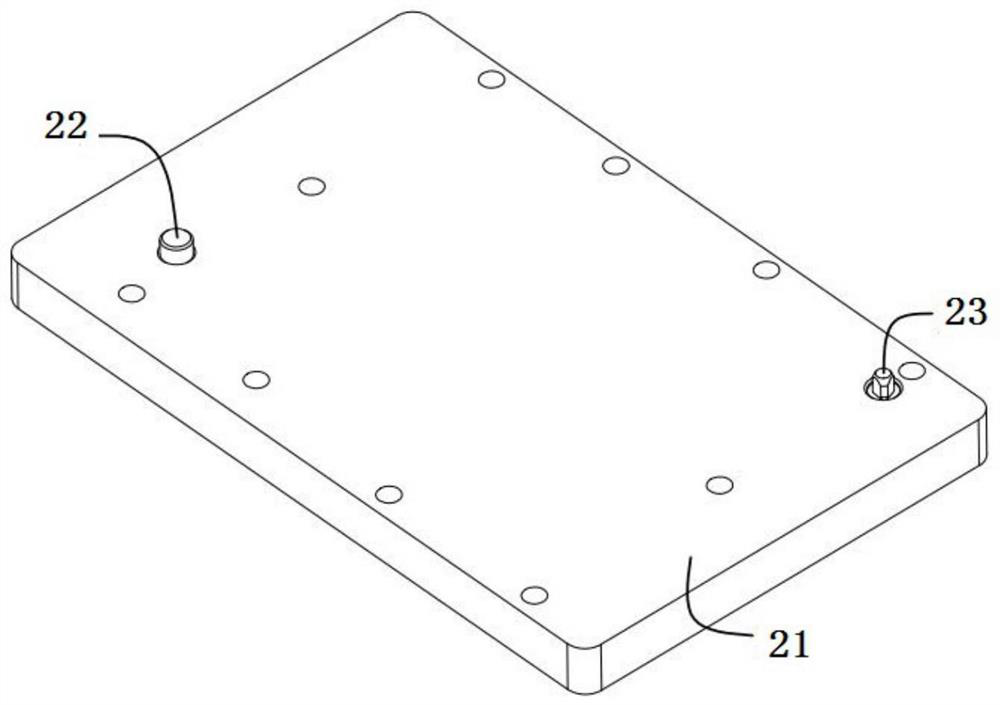

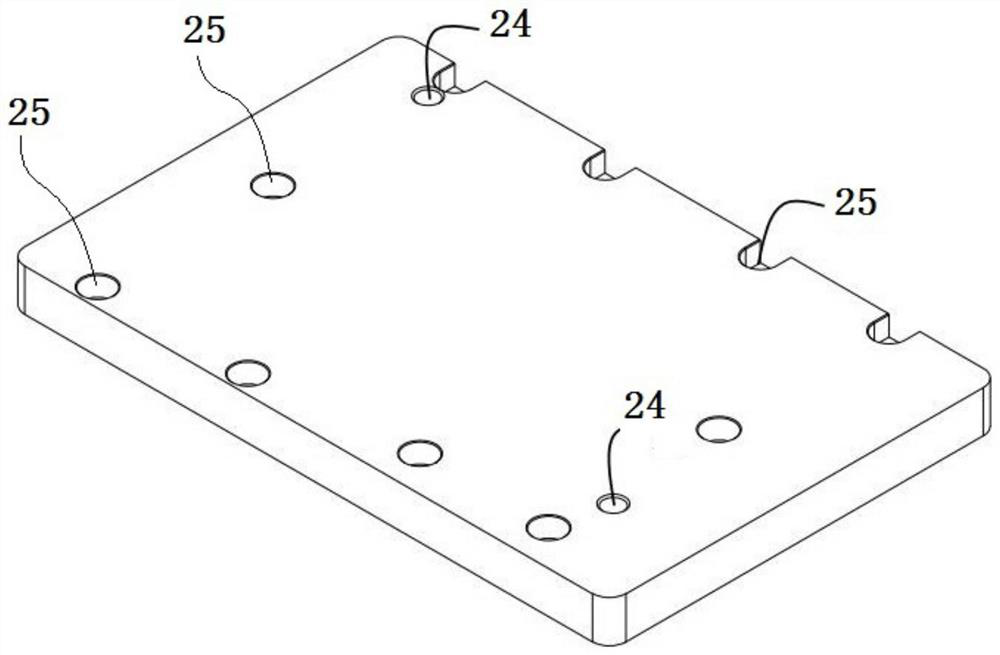

[0054] Such as figure 1 As shown, the fixture used for the finishing of the gearbox housing includes a base 1, a transition plate 2, a connecting plate 3, and a first pressing assembly 4 and an outer circle holding assembly 5 connected to the top surface of the base 1; The top surface of the transition plate 2 is connected to the window surface of the gearbox housing 9, the bottom surface of the transition plate 2 is connected to the top surface of the connecting plate 3, the bottom surface of the connecting plate 3 is connected to the base 1, and more The top end of the first pressing component 4 is pressed against the top surface of the transition plate 2 , and the outer circle clamping component 5 is clamped on the outer circle of the gearbox housing 9 .

[0055] The upper and lower sides of the base 1 are finished to ensure their flatness and parallelism, which can effectively ensure the overall rigidity, flatness and parallelism. In order to adapt to the height difference...

Embodiment 2

[0063] Such as Figure 8 As shown, on the basis of the first embodiment above, in this embodiment, the first pressing assembly 4 includes a first support rod 41, a first screw rod 42, a first pressure plate 43, and a first locking nut 44, so that The first support rod 41 and the first screw rod 42 are arranged at intervals, and the two are fixedly connected to the base 1 by means of bolts, etc., and one end of the first pressure plate 43 is hinged to the top end of the first support rod 41 , the other end of the first pressure plate 43 has a waist hole, the top of the first screw 42 passes through the waist hole, the first lock nut 44 is connected to the top of the first screw 42 to press the first pressure plate 43 Immediately on the transition plate body 21 , there are four first pressing components 4 , which are symmetrically arranged along the vertical symmetrical plane in the center of the gearbox housing 9 .

[0064] In this embodiment, the jig used for the finishing of...

Embodiment 3

[0068] Such as Figure 8 As shown, on the basis of the above-mentioned embodiment, there are two outer circle clamping components 5, which are symmetrically arranged along the vertical symmetrical plane of the center of the gearbox housing 9 .

[0069] refer to Figure 9 As shown, the outer circle tightening assembly 5 includes a support block 51, a lifting screw 52, a lifting nut 53, an abutment plate 54, and a fastening bolt 55;

[0070] The support block 51 is an inverted F-shaped structure, the bottom of which is connected to the base 1, and reinforcement ribs are added to the side, the side of the support block 51 has a U-shaped notch, and the top has an L-shaped notch. The lifting nut 53 Located in the U-shaped groove of the support block 51, the lifting screw 52 vertically passes through the upper side of the U-shaped groove. Hinged, the bottom end of the lifting screw 52 is threadedly connected to the lifting nut 53, the middle part of the abutment plate 54 is hing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com