Motor and gearbox assembling equipment and operation method thereof

A technology for assembling equipment and tooth boxes, which is applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low degree of automation, waste of labor, and low efficiency, and achieve compact structure, high efficiency, and reduced manual labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

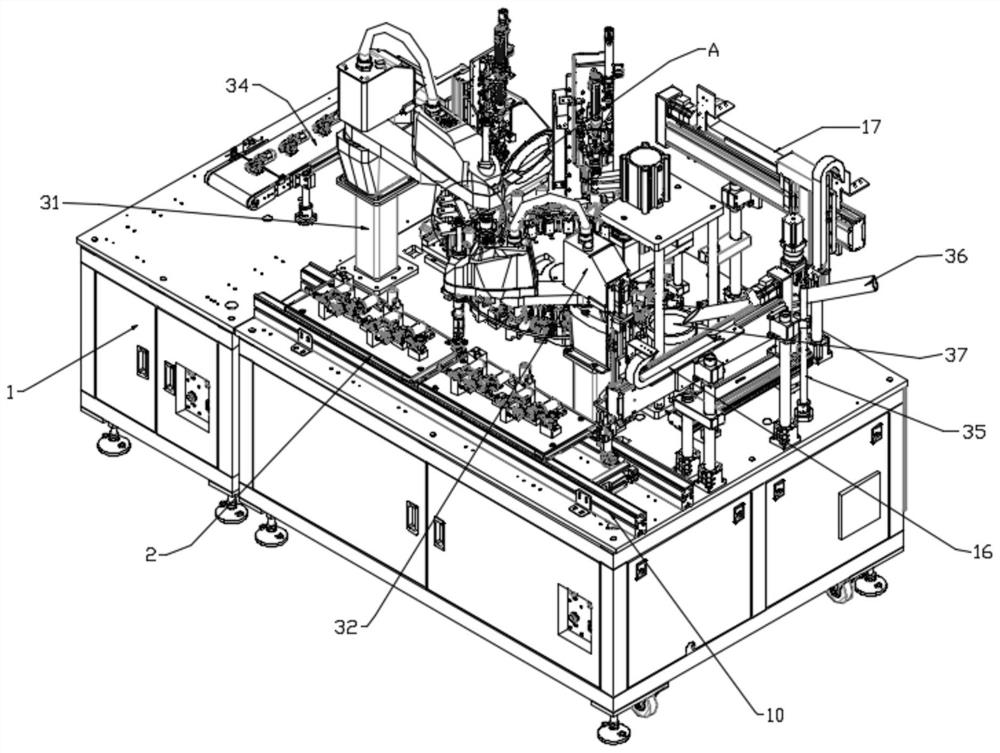

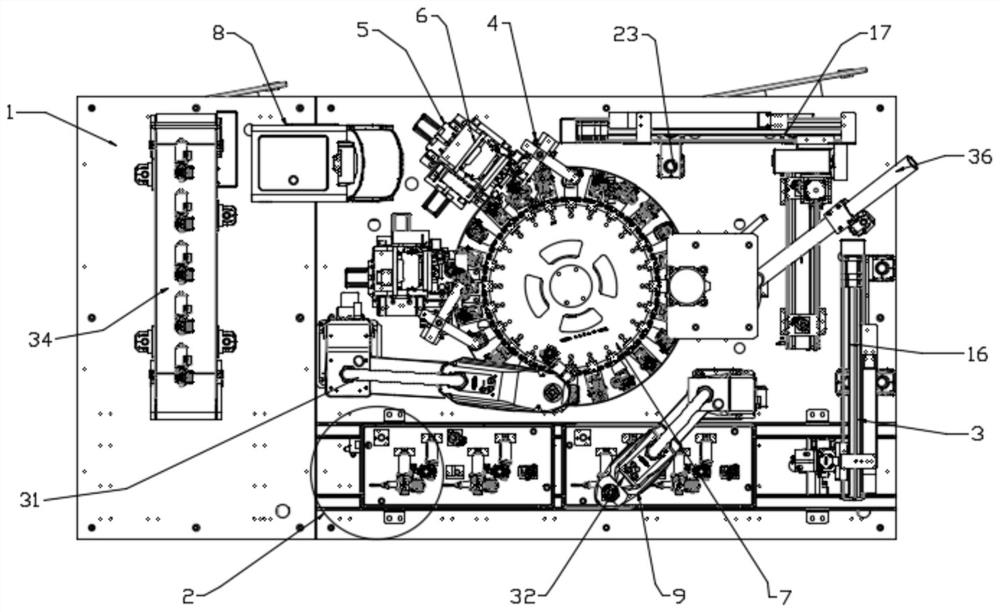

[0047] Motor and tooth box assembly equipment, including operating table 1,

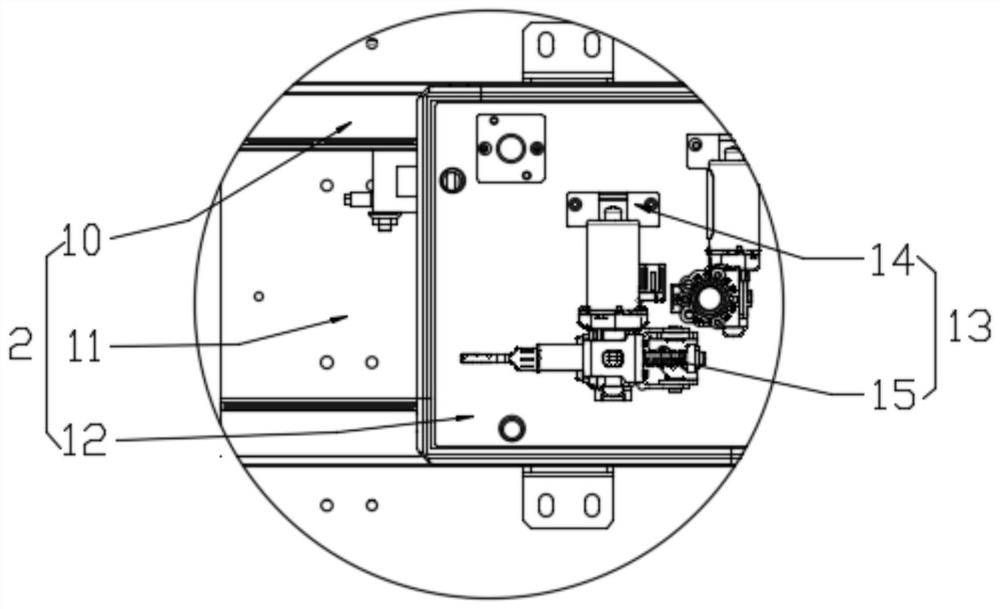

[0048] The top of the console 1 is provided with a conveying mechanism 2 for conveying dental boxes;

[0049] The material shifting mechanism 3 used for conveying the motor, the material moving mechanism 3 is located on one side of the conveying mechanism 2;

[0050] It is used to press the motor transferred by the material transfer mechanism 3 into the press-fit mechanism 4 in the tooth box, and the press-fit mechanism 4 is arranged on one side of the material transfer mechanism 3;

[0051] An assembly mechanism 5 for assembling the tooth box and the motor, the assembly mechanism 5 includes two multi-degree-of-freedom screw machines 6 installed on the top of the console 1;

[0052] A rotating mechanism 7 for placing the motor and the tooth box to be assembled in the assembly mechanism 5, and the rotating mechanism 7 is arranged at the center of the console 1;

[0053]A detection mechanism 8 for de...

Embodiment 2

[0074] The present invention also provides an operation method for the motor and tooth box assembly equipment, which specifically includes the following steps:

[0075] Step 1: first place the dental box on the conveyor belt 11 on the front side of the console 1 for transportation, then use the second manipulator 32 to transfer the dental box to the assembly station 28 corresponding to the turntable 27, and then the turntable 27 rotates to place the tooth box The box is turned to the assembly position;

[0076] Step 2: Place the motor on the material transfer mechanism 3 on the side of the console 1, then transfer it to the assembly position in a right-angle turn, then insert the motor into the tooth box, turn the turntable 27 to turn the motor and the tooth box to screw position, and then through the press-fit mechanism 4 of the screw position, use the press-fit cylinder 25 and the pressure rod 26 to press the motor into the tooth box first, and then the multi-degree-of-freed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com