Manufacturing method for multi-directional restraint rolling forming of integral structure of fuel tank

A technology of overall structure and manufacturing method, which is applied in the field of multi-directional constrained rolling forming manufacturing of the overall structure of fuel storage tanks, can solve the undiscovered continuous partial plastic forming process of fuel storage tanks, etc., and achieve improved material utilization and stability , The effect of improving manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to have a clearer understanding of the technical features, objects and effects of the present invention, the specific embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

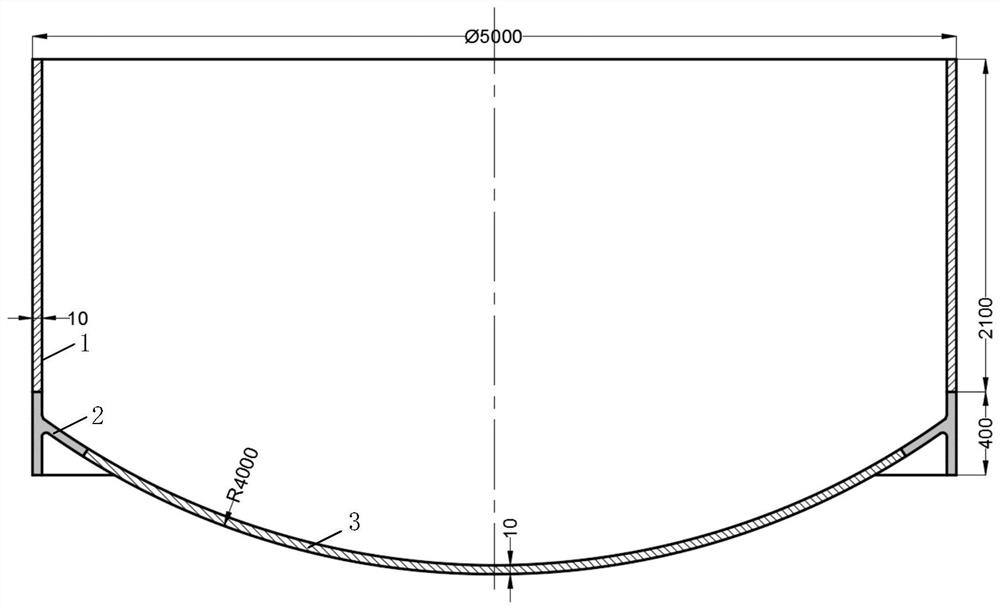

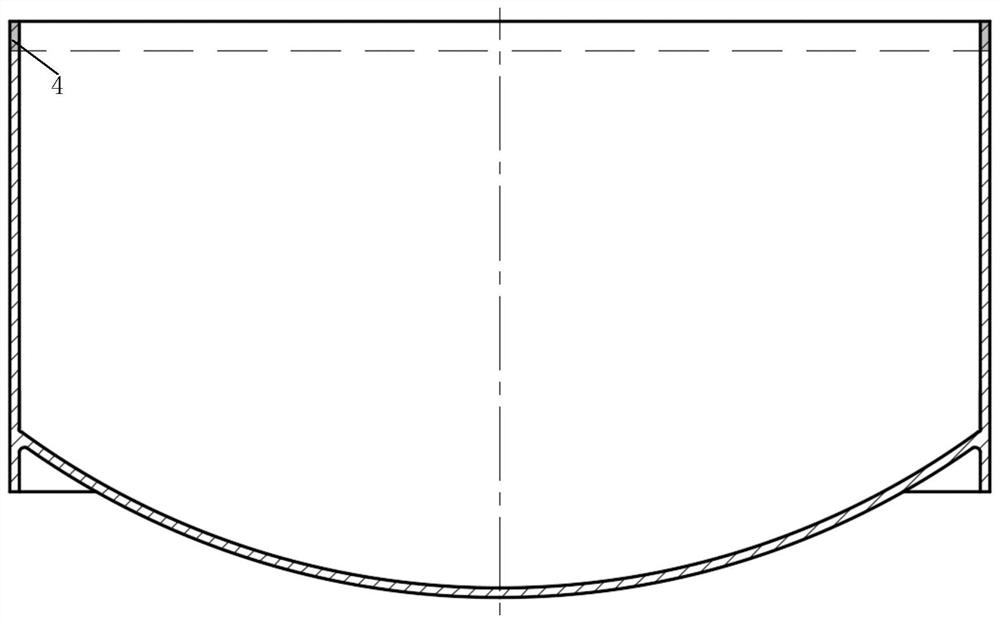

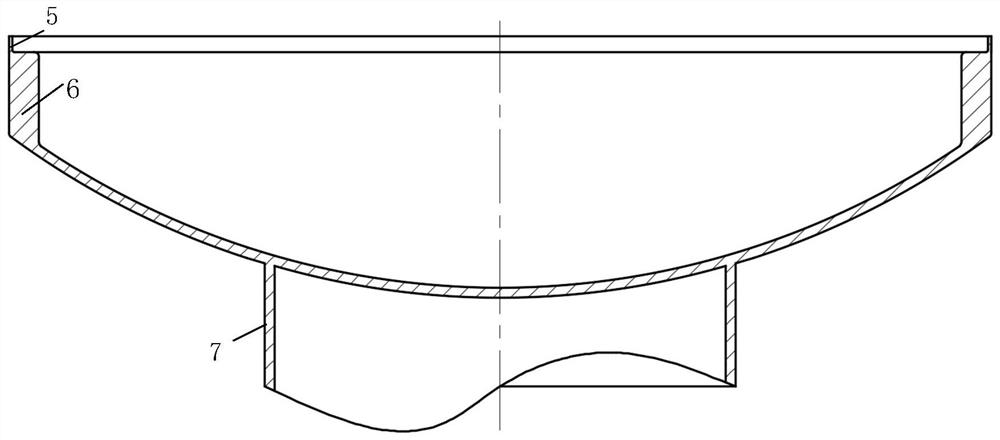

[0032] The fuel tank is composed of three parts: the cylinder body 1, the fork ring 2 and the tank bottom 3, such as figure 1 shown. The fuel tank cylinder is a thin-walled cylinder with an outer diameter of 5000mm, a wall thickness of 10mm and a height of 2800mm. The fuel tank fork ring is a ring body with a fork-shaped cross-section, which consists of a straight cylinder section and a branch section. The outer diameter and thickness of the straight cylinder section are equal to the outer diameter and thickness of the fuel tank cylinder, and its height is 400mm. The radius of the outer spherical surface is 4000mm and the thickness is 10mm. The bottom of the fuel tank is a thin-walled spherical shell structure, and its outer sphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com