Automatic finishing system and method for strip jaw coiling unit

A jaw and strip technology, applied in the field of automatic finishing system of strip jaw coiling unit, can solve the problems of not being able to take into account the jaws at the same time, unable to meet the closing requirements of the jaw coiling unit, etc., so as to improve the core of the finished coil. quality, reducing the effect of unwinding accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

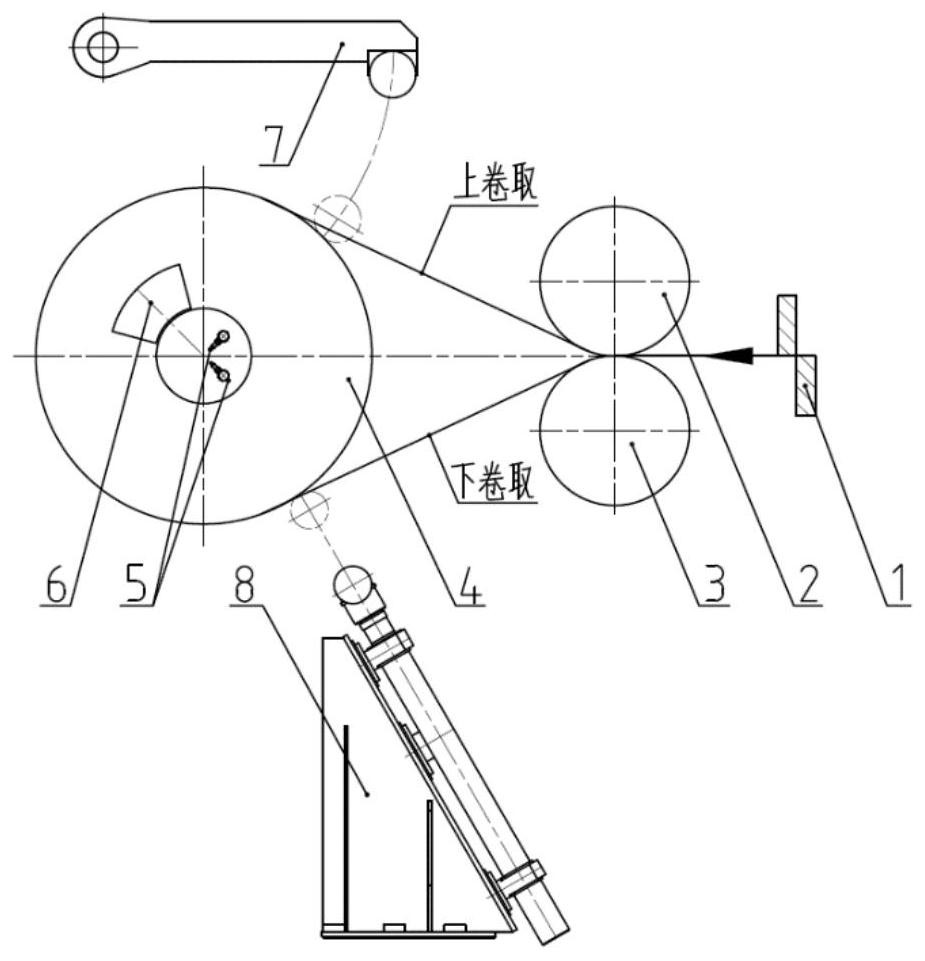

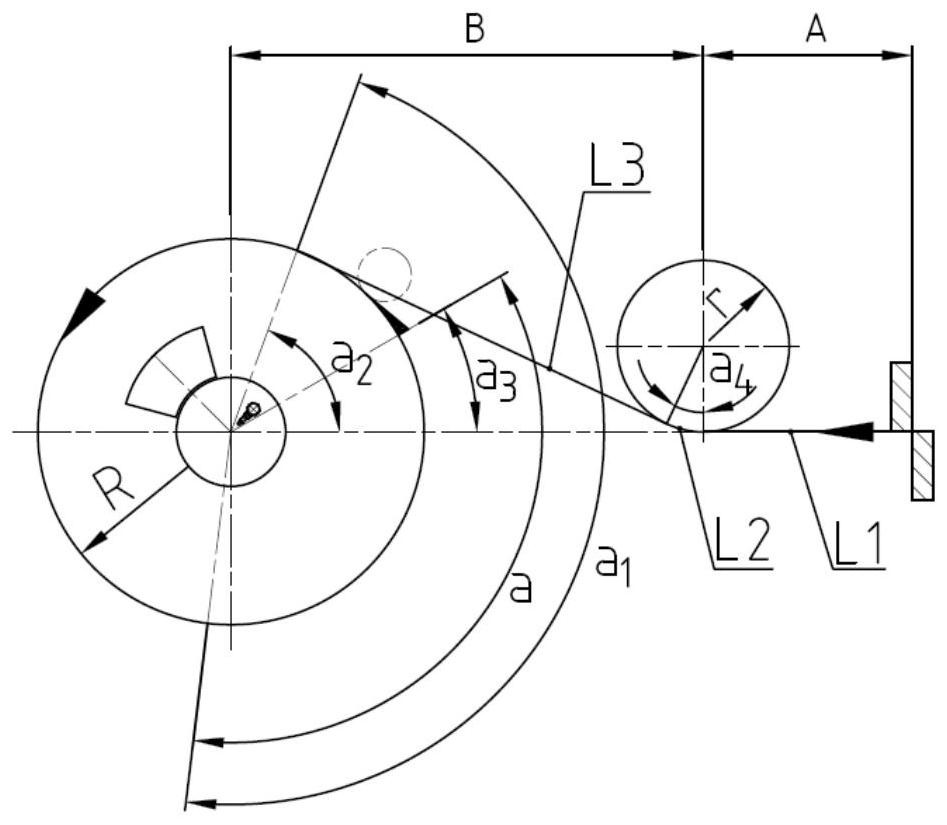

[0047] This embodiment provides an automatic finishing system for a strip jaw coiling unit, which includes a reel, a coiling pressure roller, and a slitting shear 1 arranged in sequence along the horizontal direction. The jaw is equipped with a control system and a phase detection switch 5 of the jaw. The phase detection switch 5 of the jaw is fixed at the jaw. The phase detection switch 5 of the jaw, the drum motor, and the take-up roller Both the solenoid valve and the slitting shear 1 motor are connected with the electrical signal of the control system;

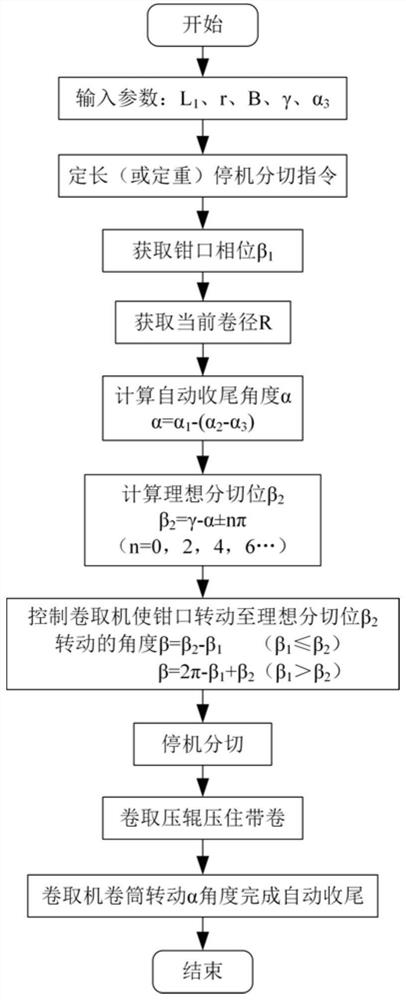

[0048]The control system includes an operation module, a parameter input module, a signal input module and a signal output module, and the operation module is used for inputting each parameter value according to the parameter input module and the jaw phase β detected by the jaw phase detection switch 5 1 Calculate the automatic closing angle α and the ideal cutting position β 2 , and then through the signal output module ...

Embodiment 2

[0052] On the basis of Embodiment 1, this embodiment provides an automatic finishing system for strip jaw coiling units, the jaw phase detection switch 5 is a reflective photoelectric switch, and the reflective photoelectric switch includes a photoelectric switch and A reflection plate, the photoelectric switch is installed on the coiler body, and the reflection plate is installed at the jaw.

[0053] In this embodiment, the jaw phase detection switch 5 is a photoelectric switch for detecting the jaw phase β 1 , Take the strip coiling direction as positive.

Embodiment 3

[0055] On the basis of Embodiment 1, this embodiment provides an automatic finishing system for the strip nip coiling unit. The parameters input through the parameter input module include the distance between the cutting edge of the slitting shear 1 and the center of the exit turning roller. distance L 1 , the radius r of the exit turning roller, the distance B between the center of the exit turning roller and the center of the reel of the coiler, the phase γ of the coil unloading push plate 6 of the coiler, and the phase angle of the tape tail after the automatic tailing is completed α 3 .

[0056] For each coiling unit, after the on-site layout and assembly are completed, there are many parameters that are fixed values. Input these parameters in advance, and calculate the automatic closing angle α and the ideal cutting position β through the calculation module 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com