Inflation device with adjustable thermal resistance

An inflatable device and thermal resistance technology, applied in the field of clothing, can solve the problems of insufficient thermal resistance improvement, narrow effective adjustment range of thermal resistance, low still air content and holding ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

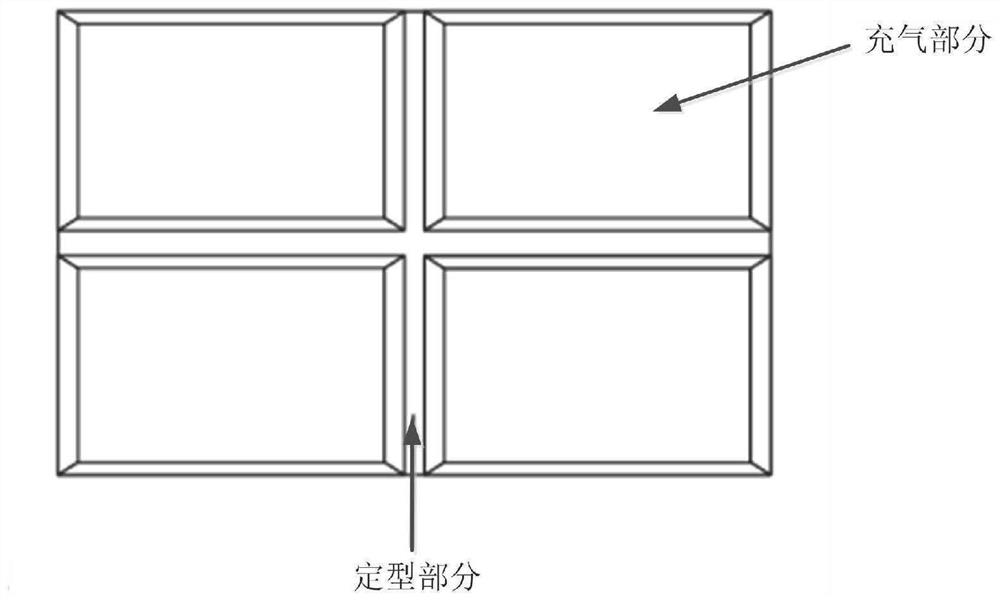

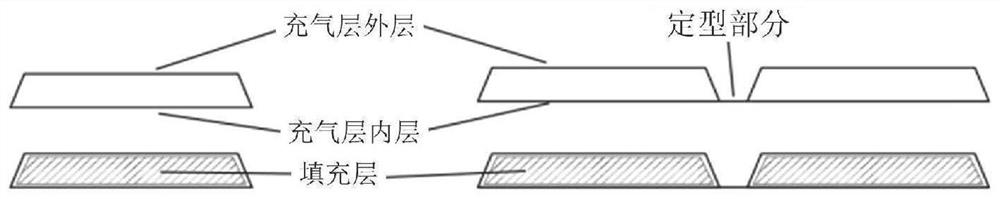

[0025] The invention discloses an adjustable thermal resistance inflatable device, such as figure 1 and 2 As shown, it specifically includes an air-filled layer and a filling layer; the air-filled layer includes an inner layer close to the human skin and an outer layer far away from the human skin, and the edges of the inner layer and the outer layer are connected to form a sealed cavity, and the sealed cavity A plurality of inflatable parts and shaped parts are set in the room, and the inflated parts and shaped parts form air bags for storing gas, wherein the inflated parts and shaped parts are distributed at regular intervals; the filling layer is located inside the air bag, to stabilize the gas inside the airbag.

[0026] It should be noted that the thermal resistance of clothing or materials depends on the content of still air inside, and still air is currently known as one of the best ways of heat insulation. The improvement of the thermal resistance of traditional infl...

Embodiment 2

[0029] The invention discloses an adjustable thermal resistance inflatable device, such as figure 1 and 2 As shown, it specifically includes an air-filled layer and a filling layer; the air-filled layer includes an inner layer close to the human skin and an outer layer far away from the human skin, and the edges of the inner layer and the outer layer are connected to form a sealed cavity, and the sealed cavity A plurality of inflatable parts and shaped parts are set in the room, and the inflated parts and shaped parts form air bags for storing gas, wherein the inflated parts and shaped parts are distributed at regular intervals; the filling layer is located inside the air bag, to stabilize the gas inside the airbag.

[0030] Wherein, the inner layer of the air-filled layer has a planar structure, which can better fit the human body so as to form a static air layer. The outer layer of the inflatable layer has a three-dimensional structure, so that when the gas in the inflatab...

Embodiment 3

[0032] A gas-filled device with adjustable thermal resistance, such as figure 1 and 2 As shown, it specifically includes an air-filled layer and a filling layer; the air-filled layer includes an inner layer close to the human skin and an outer layer far away from the human skin, and the edges of the inner layer and the outer layer are connected to form a sealed cavity, and the sealed cavity A plurality of inflatable parts and shaped parts are set in the room, and the inflated parts and shaped parts form air bags for storing gas, wherein the inflated parts and shaped parts are distributed at regular intervals; the filling layer is located inside the air bag, to stabilize the gas inside the airbag.

[0033] The materials used in the inner and outer layers are all air-tight materials, such as high-density, coated fabrics, PVC films and other air-tight materials, so that the inflatable part can form a closed space for storing gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com