Processing Technology of Quickly Refreshing Walnut

A processing technology, fresh walnut technology, applied in the field of food processing, can solve the problems of short sales radius, difficult storage of fresh walnut kernels, and long rehydration time, so as to improve rehydration efficiency, shorten rehydration time, and reduce oil content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

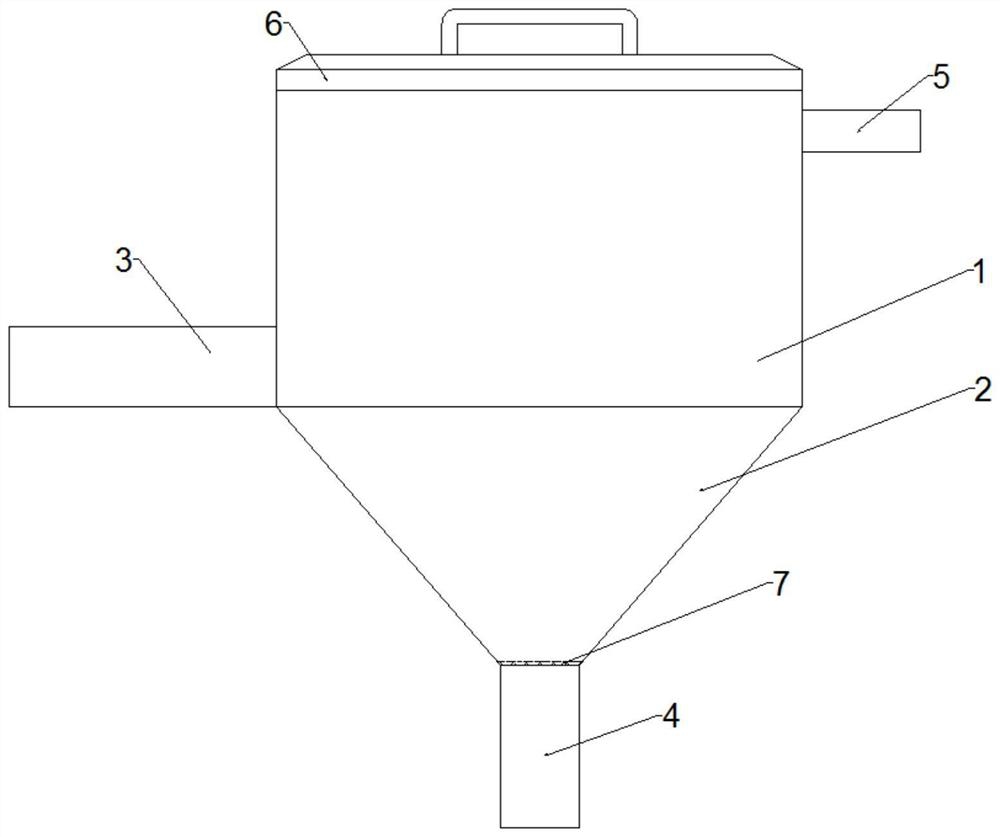

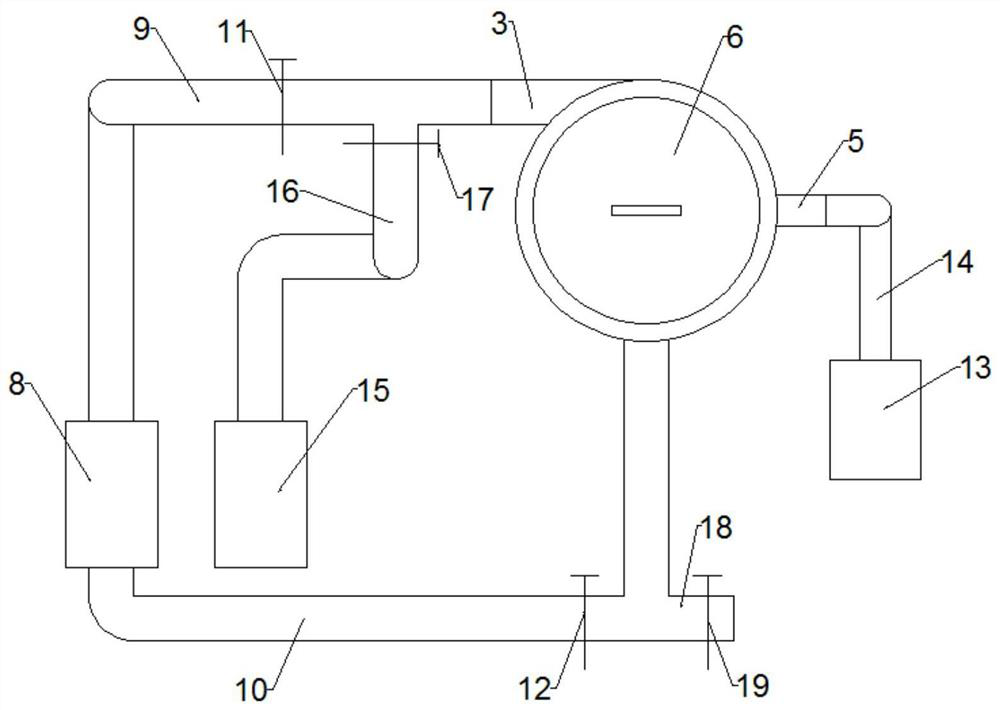

Method used

Image

Examples

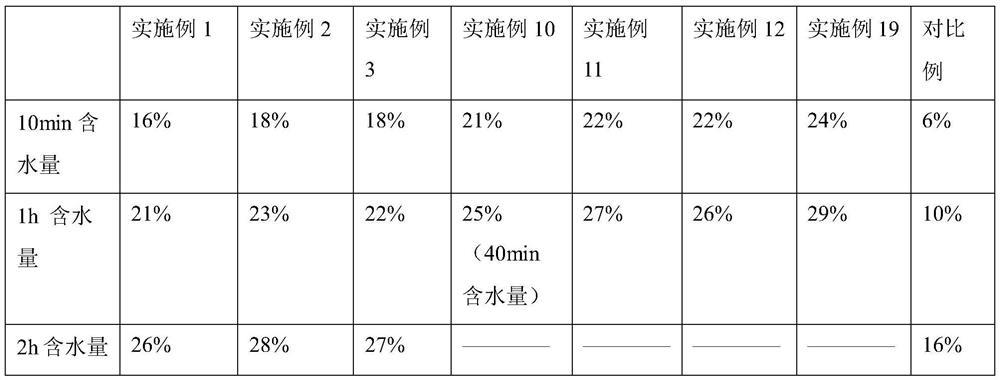

Embodiment 1

[0039] A kind of processing technology of fresh walnut fast, it comprises the following steps:

[0040] Dried walnut kernels with a moisture content of 2% were first pressed statically at 10 MPa for 5 minutes at 60° C., and then statically hydraulically pressed at 15 MPa for 15 minutes to remove 20 percent of the oil from the walnut kernels.

[0041] Soak the squeezed walnut kernels in water to moisten the water. When the water content of the walnut kernels reaches 6%, take them out, and then carry out vacuum microwave puffing. The vacuum degree of vacuum microwave puffing is 0.6MPa, the power is 600W, and the duration is 3min. Until the water content of walnut kernel is 2%.

[0042] Dissolve konjac gum, CMC-Na, locust bean gum, xanthan gum, and citric acid in water at 50°C, and cool to 30°C to obtain an edible water-absorbing gel solution. In the edible water-absorbing gel solution, konjac gum, CMC - The total mass concentration of Na, locust bean gum and xanthan gum is 0.05%,...

Embodiment 2

[0046] A kind of processing technology of fresh walnut fast, it comprises the following steps:

[0047] Dry walnut kernels with a water content of 3% at 80°C, first use 15MPa pressure static hydraulic pressing for 5 minutes, and then use 25MPa pressure static hydraulic pressing for 15 minutes to remove 30% of the walnut kernel oil

[0048] Soak the squeezed walnut kernels in water to moisten the water. When the water content of the walnut kernels reaches 10%, take them out, and then carry out vacuum microwave puffing. The vacuum degree of vacuum microwave puffing is 0.8MPa, the power is 800W, and the duration is 5min. Until the water content of walnut kernel is 4%.

[0049] Dissolve konjac gum, CMC-Na, locust bean gum, xanthan gum, and citric acid in water at 90°C, and cool to 60°C to obtain an edible water-absorbing gel solution. In the edible water-absorbing gel solution, konjac gum, CMC The total mass concentration of Na, locust bean gum and xanthan gum is 0.2%, and the ma...

Embodiment 3

[0053] A kind of processing technology of fresh walnut fast, it comprises the following steps:

[0054] Dry walnut kernels with a moisture content of 2% are first pressed statically at 13 MPa for 5 minutes at 70° C., and then statically pressed at 20 MPa for 15 minutes to remove 25 percent of the oil from the walnut kernels.

[0055] Soak the squeezed walnut kernels in water to moisten the water. When the water content of the walnut kernels reaches 8%, take them out, and then carry out vacuum microwave puffing. The vacuum degree of vacuum microwave puffing is 0.7MPa, the power is 700W, and the duration is 4min. Until the water content of walnut kernel is 3%.

[0056] Dissolve konjac gum, CMC-Na, locust bean gum, xanthan gum, and citric acid in water at 70°C, and cool to 45°C to obtain an edible water-absorbing gel solution. In the edible water-absorbing gel solution, konjac gum, CMC - The total mass concentration of Na, locust bean gum and xanthan gum is 0.1%, and the mass co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com