Water-based formaldehyde-free adhesive for flame-retardant composite board and preparation method thereof

An aldehyde adhesive, water-based technology, applied in the field of water-based formaldehyde-free adhesive for flame-retardant composite panels and its preparation, can solve problems such as physical damage, unimaginable consequences, and rapid spread, and achieve enhanced tensile strength and durability Grinding performance, effect of reducing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

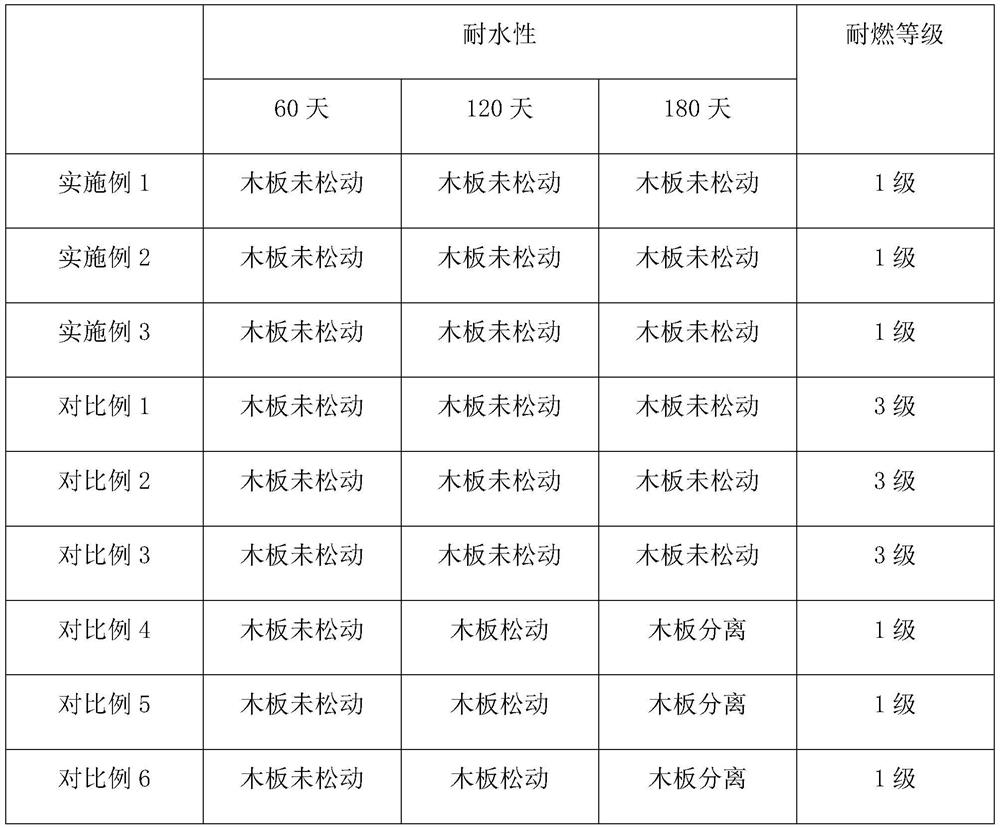

Examples

Embodiment 1

[0042] A method for preparing a water-based formaldehyde-free adhesive for a flame-retardant composite board, comprising the following steps:

[0043] S1: reacting aluminum nitrate nonahydrate with sodium fumarate to prepare a fumaric acid-aluminum complex;

[0044] S2: Preparation of network polyurethane, coated with 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide to obtain 9,10-dihydro-9-oxa-10-phospha Phenanthrene-10-oxide complex;

[0045] S3: reacting soybean polysaccharide with isocyanate to prepare microencapsulated isocyanate;

[0046] S4: Mix fumaric acid-aluminum complex, 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide complex, microencapsulated isocyanate and defatted soy flour to prepare adhesive agent.

[0047] Among them, S1:

[0048] Mix aluminum nitrate nonahydrate with deionized water, heat in a water bath to 30°C, stir for 10 minutes, add sodium fumarate, heat in a water bath to 45°C, stir for 20 minutes, ultrasonically oscillate for 20 minutes, fil...

Embodiment 2

[0056] A method for preparing a water-based formaldehyde-free adhesive for a flame-retardant composite board, comprising the following steps:

[0057] S1: reacting aluminum nitrate nonahydrate with sodium fumarate to prepare a fumaric acid-aluminum complex;

[0058] S2: Preparation of network polyurethane, coated with 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide to obtain 9,10-dihydro-9-oxa-10-phospha Phenanthrene-10-oxide complex;

[0059] S3: reacting soybean polysaccharide with isocyanate to prepare microencapsulated isocyanate;

[0060] S4: Mix fumaric acid-aluminum complex, 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide complex, microencapsulated isocyanate and defatted soy flour to prepare adhesive agent.

[0061] Among them, S1:

[0062] Mix aluminum nitrate nonahydrate with deionized water, heat in a water bath to 30°C, stir for 15 minutes, add sodium fumarate, heat in a water bath to 45°C, stir for 25 minutes, ultrasonically oscillate for 25 minutes, fil...

Embodiment 3

[0070] A method for preparing a water-based formaldehyde-free adhesive for a flame-retardant composite board, comprising the following steps:

[0071] S1: reacting aluminum nitrate nonahydrate with sodium fumarate to prepare a fumaric acid-aluminum complex;

[0072] S2: Preparation of network polyurethane, coated with 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide to obtain 9,10-dihydro-9-oxa-10-phospha Phenanthrene-10-oxide complex;

[0073] S3: reacting soybean polysaccharide with isocyanate to prepare microencapsulated isocyanate;

[0074] S4: Mix fumaric acid-aluminum complex, 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide complex, microencapsulated isocyanate and defatted soy flour to prepare adhesive agent.

[0075] Among them, S1:

[0076] Mix aluminum nitrate nonahydrate with deionized water, heat in a water bath to 30°C, stir for 20 minutes, add sodium fumarate, heat in a water bath to 45°C, stir for 30 minutes, ultrasonically oscillate for 30 minutes, fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com