A special-shaped pipe door structure for construction machinery cab

A technology for construction machinery and special-shaped pipes, which is applied in the field of vehicle engineering, can solve problems such as easy falling off, and achieve the effects of increasing the support and bending resistance, improving the utilization rate of materials, and simplifying the materials required for fixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

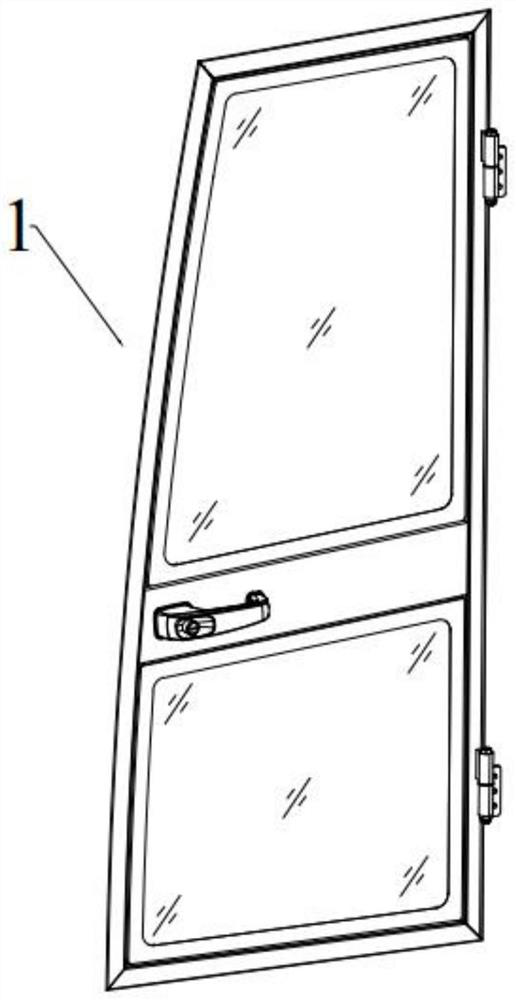

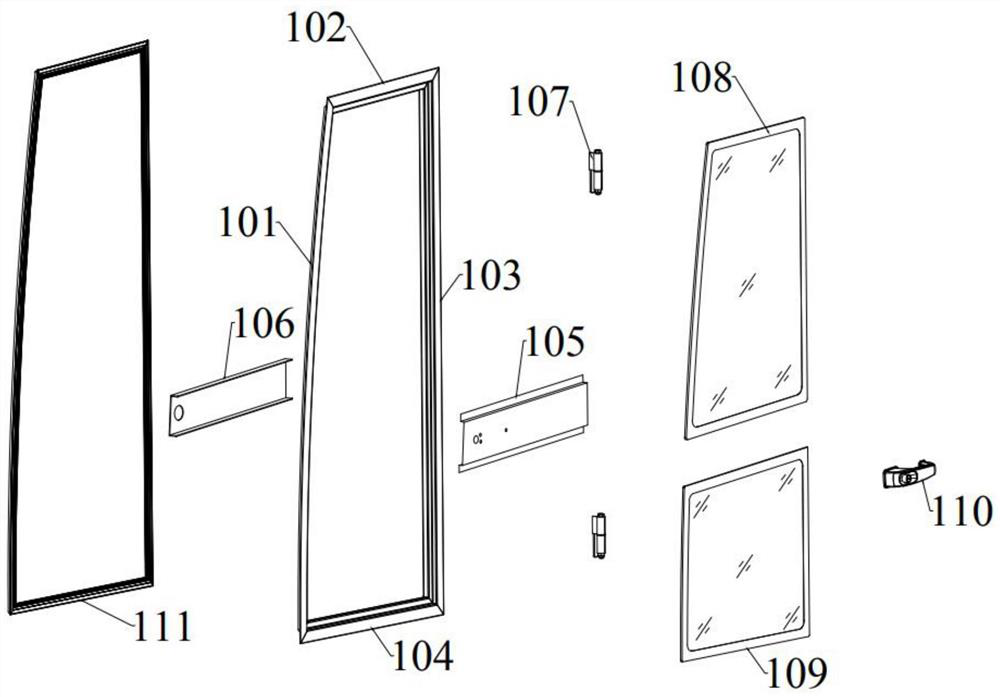

[0036] A construction machinery cab profift trunk door structure, such as figure 1 As shown, the main body structure is the door frame 1. Combine figure 2 As shown, the door frame 1 includes a pre-outer profile 101, an upper oriented tube 102, a post-mortal tube 103, a lower isofolding tube 104; wherein the front profile 101 is close to the position of the front of the front, the rear Digital tube 103 is close to The position behind the body.

[0037] The outer cross beam 105 and the inner beam 106 in the middle of the door frame 1 are applied. The lateral length of the inner and outer beam is slightly longer than the side pitch 101 and the rear transfection tube 103, and the inner and outer beam is fixed to the front axis 101 and the rear. Tube. On the 103, the two extensions are clamped.

[0038] The door handle 110 is mounted on the outer beam 105; the post-transforming tube 103 is connected to the body structure by two hinge 107 provided up and down. The door frame 1 side is p...

Embodiment 2

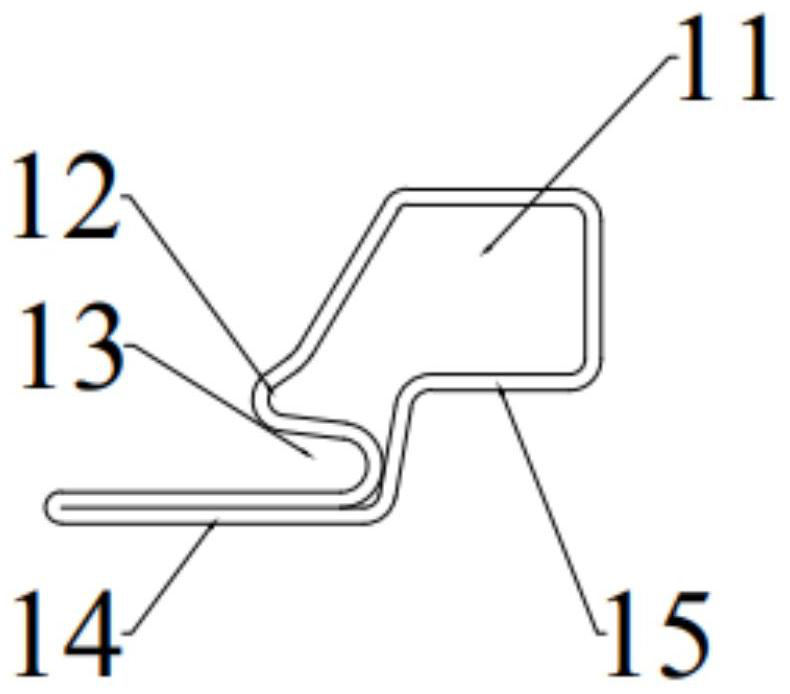

[0044] On the basis of Example 1, if Figure 4 As shown, the right angle side of the support chamber 11 in this embodiment is the arc portion 16 structure. The arc portion 16 is formed at the side of the arc, and the center of the arc portion 16 is bent at the center of the arc portion 16, which may not increase the lateral width of the shaped tube, and enhance vertical support capacity, and, in the case where the door is lateral impact Finite deformation absorbs impact energy and plays a certain protection. The specific curved rounded corners can be used in theoretical modeling analysis and experimental verification according to actual needs.

Embodiment 3

[0046] On the basis of Example 2, if Figure 5 , 7 As shown, the fold 14 of the upper and differential tube 104 of the present embodiment is laterally inclined laterally, that is, the flap 14 is connected to the glass mounting surface 15 to form a convex portion 17; convex portions 17 A angle structure is formed between the glass mounting surface 15 and the angle is an acute angle. As shown in the figure, in the actual folding 14, a cavity structure is increased to a certain extent, and the outer tube support, the bending ability, and the angle structure formed can be used to plug the upper and lower glass.

[0047] Correspond Image 6 As shown, the outer beam 105 is provided with a sub-grooved ride structure, and the convex edge is formed at an angle structure at the outer surface of the outerveral beam 105, and the upper and lower glass can be inserted into the angle structure and angle. For acute.

[0048] Specific installation, such as Figure 8 As shown, first, both ends, the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com