Buffering type plastic particle multidirectional screening device

A screening device and technology for plastic particles, applied in the field of multi-directional screening devices for buffered plastic particles, can solve problems such as hole blockage, difficulty in air-drying, and difficulty in multi-directional buffer discharge of plastic particles, etc., to achieve convenient cleaning and convenient discharge Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

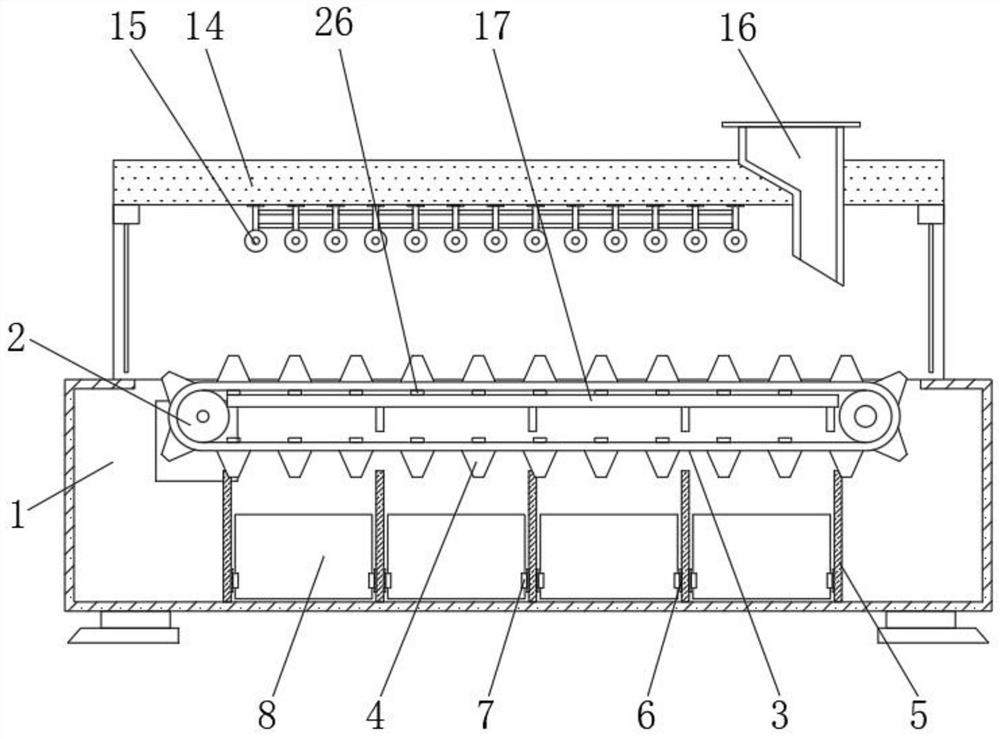

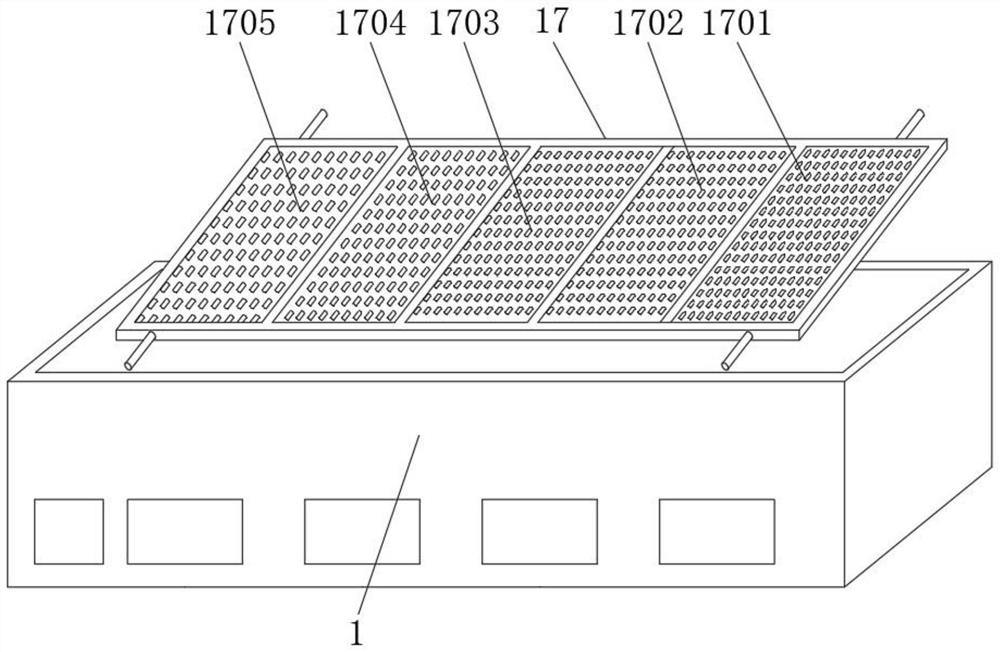

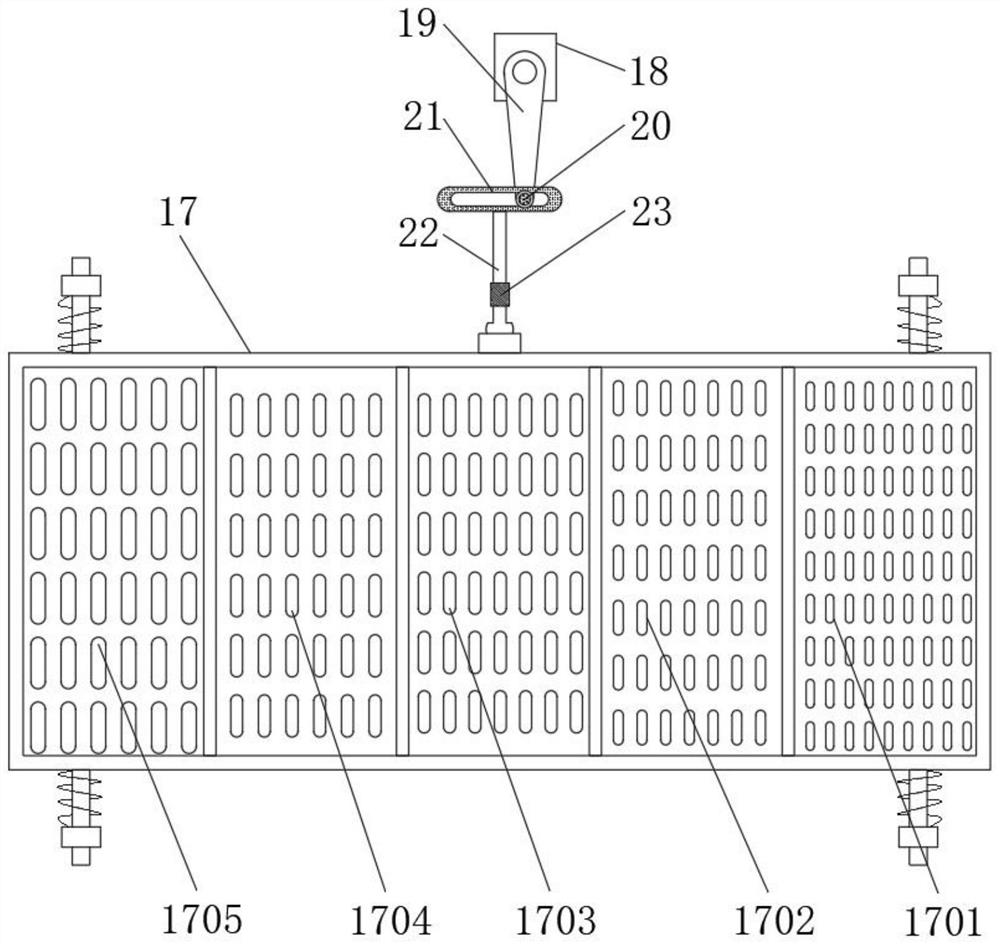

[0040] see Figure 1-6 , a buffer type plastic particle multi-directional screening device, comprising a screening box 1, a roller 2 is installed on the left side of the screening box 1 for rotation, the outer surface of the roller 2 is connected with a conveyor belt 3, and the outer surface of the conveyor belt 3 is fixed A blocking shaft 4 is installed, and a partition panel 5 is fixedly installed inside the bottom of the screening box 1. The inner side of the partition panel 5 is connected with a turning block 6, and the inner end of the turning block 6 is connected with a limiting groove 7, and the inner side of the limiting groove 7 is connected There is an adjustment panel 8, the lower side of the middle part of the adjustment panel 8 is connected with an output shaft 9, the outside of the output shaft 9 is fixedly connected with an adjustment block 10, the outside of the adjustment block 10 is connected with a positioning frame 11, and the upper surface of the positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com