Polishing device on light conveying belt production line

A light-duty conveyor belt and production line technology, applied in the direction of grinding drive device, grinding/polishing safety device, grinding machine, etc., can solve the problems such as the inability to control the grinding degree of the conveyor belt surface, the contamination of the working environment by flying debris, etc., and increase the range of motion , Healthy working environment, stable grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

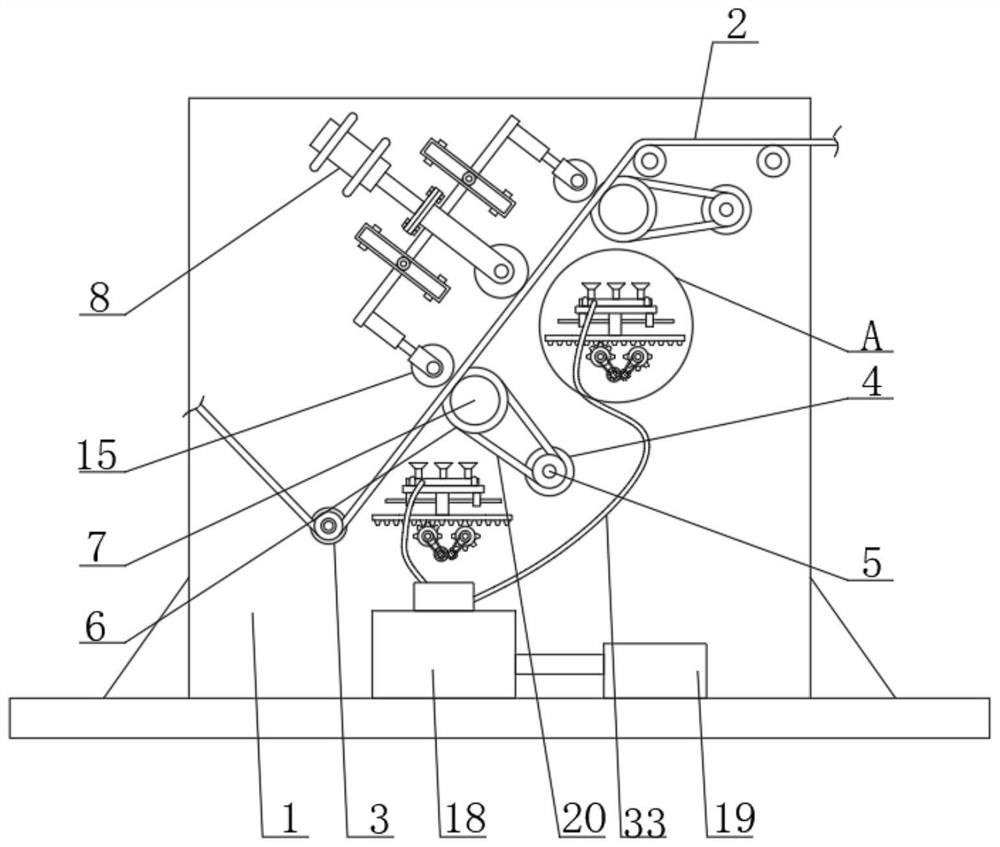

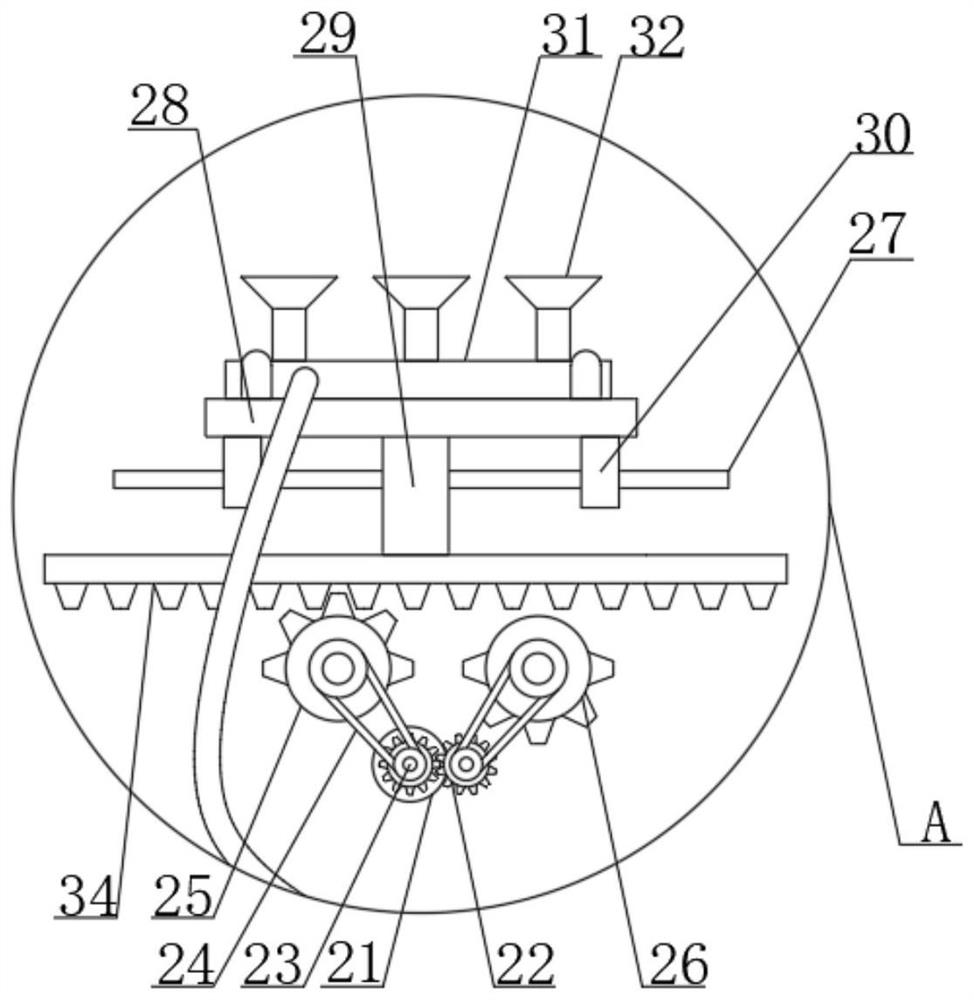

[0027] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 6 and Figure 7 , a grinding device on a light conveyor belt production line, comprising a fixed frame 1; a sanding roller 7; and a cylinder 8; the fixed frame 1 is fixedly connected with a first motor 4, and the output shaft of the first motor 4 is fixedly connected There is a first pulley 5, and a second pulley 6 is also rotatably connected to the fixed frame 1, and the second pulley 6 is fixedly connected with the grinding roller 7, and the first pulley 5 and the second pulley 6 are connected through the transmission of the first belt 20;

[0028] Also be fixedly connected with cylinder 8 on described fixed mount 1, on described fixed mount 1, also be installed with pinching roller 9 by mounting seat rotation, the piston rod of described cylinder 8 is fixedly connected with the mounting seat on pinching roller 9;

[0029] Wherein, the pinch roller 9 is rotatably installed on the mounting seat, and the mo...

Embodiment 2

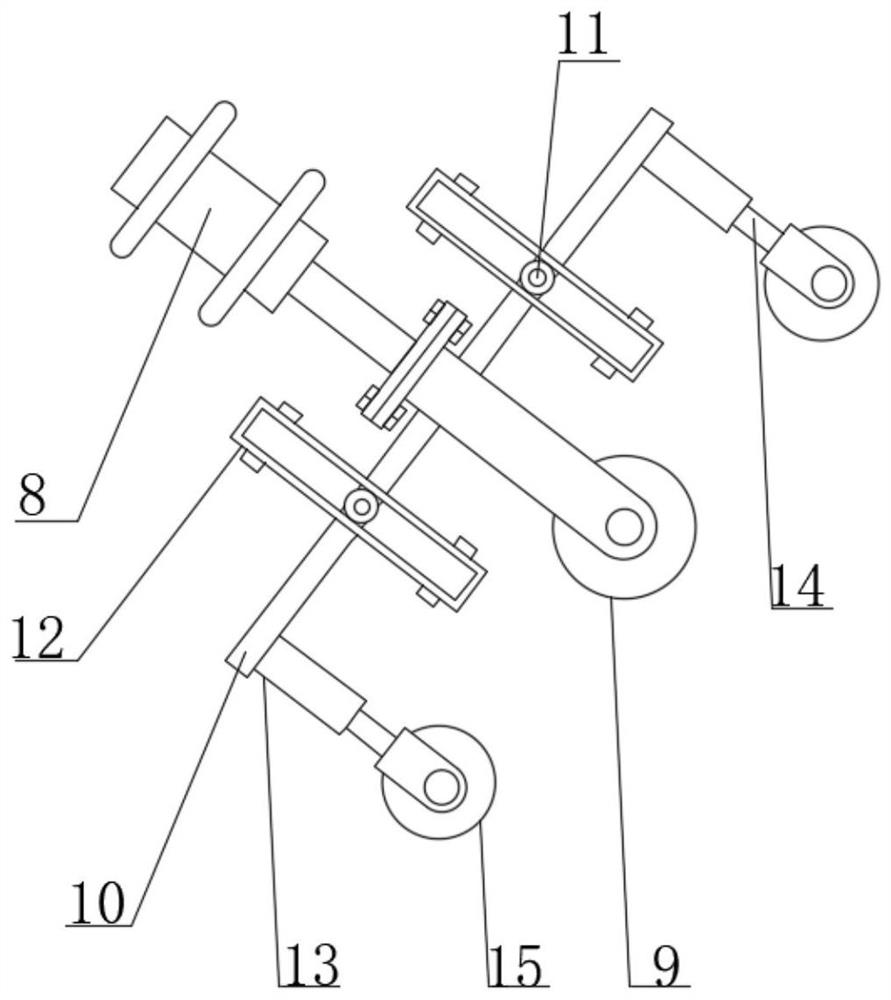

[0049] As a preferred solution of Embodiment 1, please refer to figure 1 , figure 2 and Figure 5 , both ends of the mounting seat on the pressure roller 9 are fixedly connected with a fixed plate 10, one end of the fixed plate 10 is fixedly connected with a sleeve 13, and a sleeve rod 14 is slidably connected in the sleeve 13, so The sleeve rod 14 is fixedly connected with the mounting frame on the adjustment wheel 15 after passing through the sleeve pipe 13, and one end of the sleeve rod 14 is also fixedly connected with a slide plate 17, and the sleeve rod 14 is also sleeved with a spring 16, and the The two ends of the spring 16 are respectively fixedly connected with the slide plate 17 and the inner wall of the casing 13;

[0050] Wherein, the spring 16 can absorb the shock generated when the conveyor belt body 2 is polished;

[0051] Wherein, the adjustment wheel 15 is rotatably installed on the fixed mount 1, and the fixed mount 1 is fixedly connected with the cover...

Embodiment 3

[0055] As a preferred solution of Embodiment 1 or Embodiment 2, please refer to figure 1 and figure 2 , on the fixed plate 10, a slide block 11 is also rotatably installed, and the position of the slide block 11 corresponding to the fixed plate 10 is also fixedly connected with a rectangular frame 12, and the slide block 11 is slidably connected to the rectangular frame 12;

[0056] Wherein, the slider 11 is a cylindrical structure;

[0057] Working principle: When the piston rod of the cylinder 8 drives the pressure roller 9 to move, the fixed plate 10 drives the slider 11 to slide in the rectangular frame 12, which guides the piston rod of the cylinder 8 and makes the pressure roller 9 move more smoothly. smooth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com