Inner supporting type pipe end face automatic welding and cutting groove machining equipment

A technology for cutting bevels and processing equipment, which is applied in metal processing equipment, turning equipment, turning equipment, etc. It can solve the problems of heavy weight, inconvenience, automatic centering and clamping, and large volume, and achieve the effect of volume and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

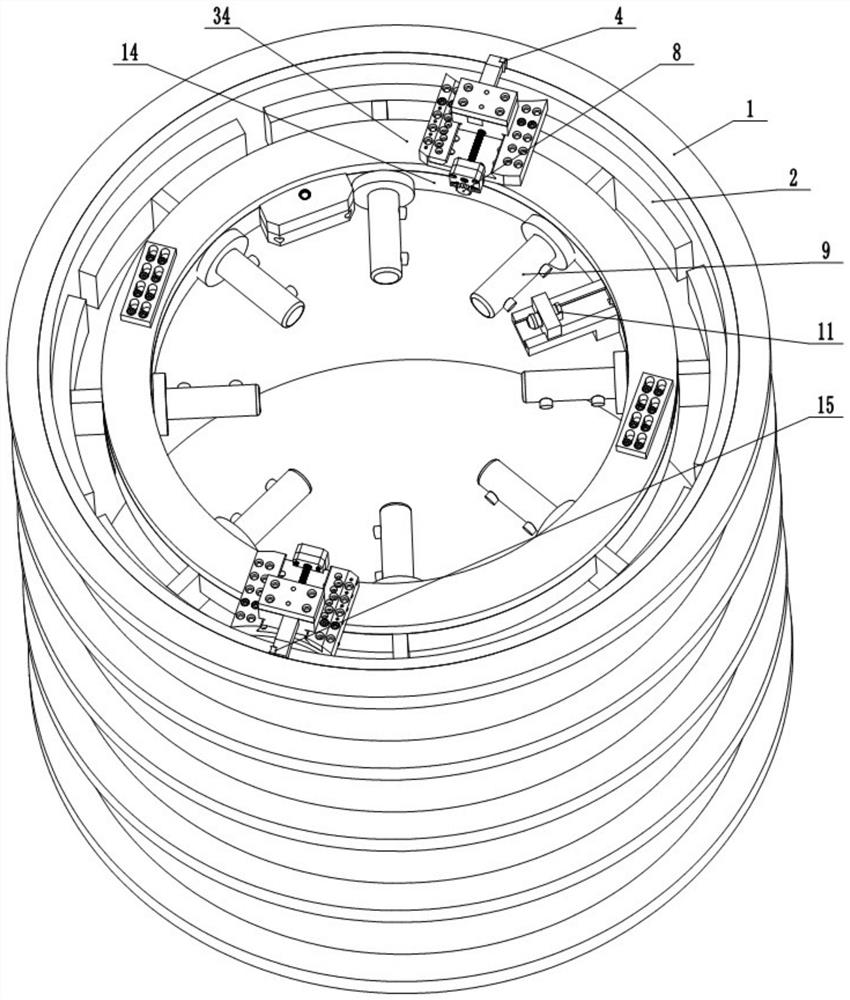

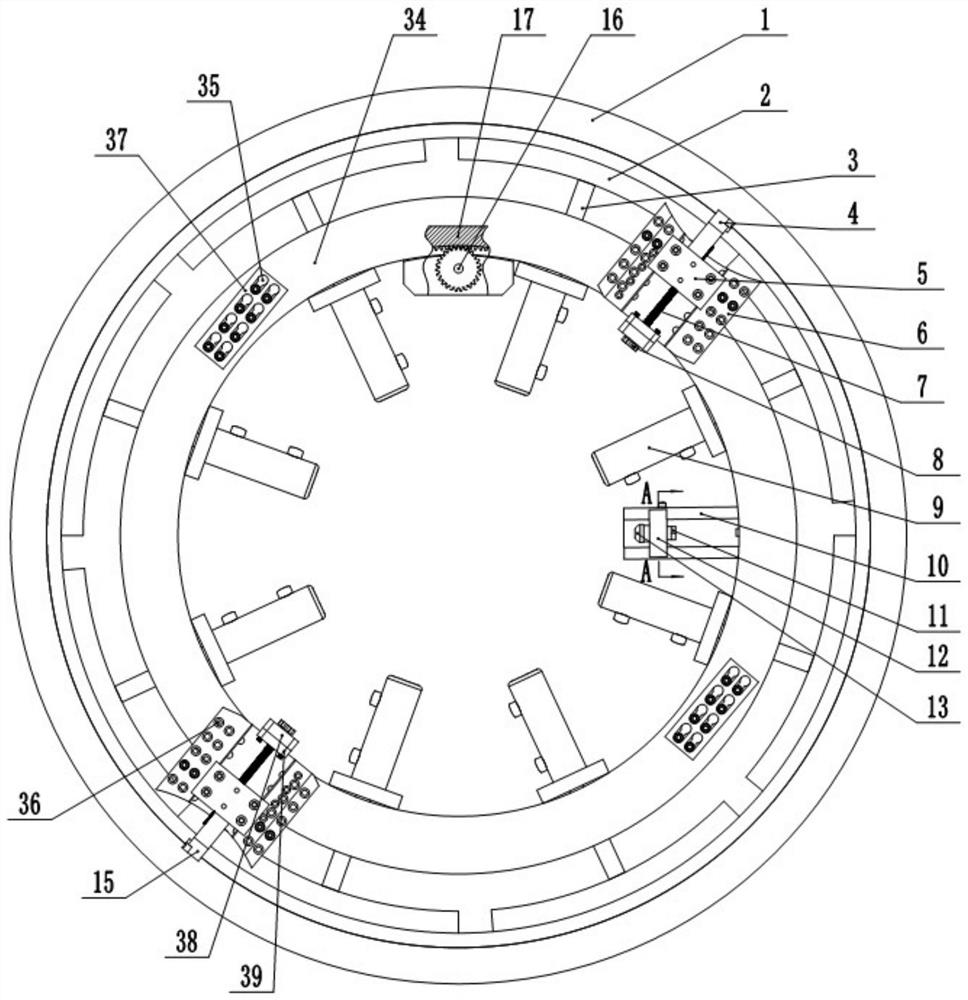

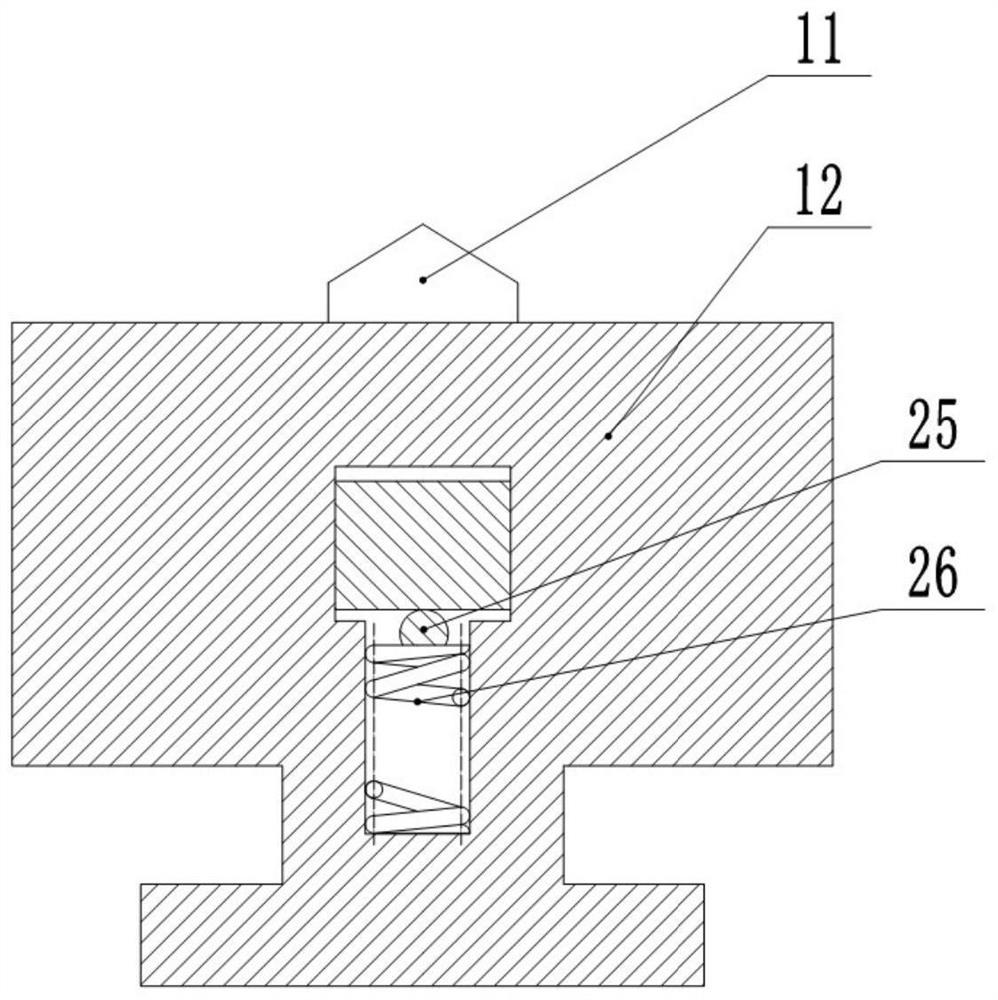

[0033] Embodiment one is basically as attached figure 1 and figure 2Shown: inner support type pipe end face automatic welding and cutting groove processing equipment, including machine body 14, expansion mechanism assembly, rotating toothed disk 17, active transmission mechanism for driving rotating toothed disk 17 and cutting pipe fittings 1 Mechanical cutting actuator for beveling and cutting off pipe fittings 1. The active transmission mechanism includes a motor and a drive gear 16 , the output shaft of the motor is fixedly connected with the drive gear 16 , and the drive gear 16 meshes with the rotary toothed disc 17 . The mechanical cutting executive mechanism includes a groove forming cutting mechanism, a cutting cutting mechanism and an active tool feeding mechanism. Knife rest seat, cut-off knife 15 clamping knife block and cut-off knife 15.

[0034] The body 14 is annular and hollow inside, and the rotating toothed disc 17 is also annular and embedded in the body ...

Embodiment 2

[0050] Embodiment two is basically as attached Figure 4 Shown: the difference between the second embodiment and the first embodiment is that the driving device includes a piston cylinder 20, a piston 22, a compression chamber 19, a sealing compression plate 28, a driving block 31, a rotating screw 29, and a driven pulley 24 and driving pulley 18.

[0051] One end of the expansion block 2 and the expansion adjustment rod 3 is fixedly connected together, and the expansion block 2 and the expansion adjustment rod 3 are hollow inside and communicate with each other, and the side of the expansion block 2 in contact with the inner wall of the pipe fitting 1 , with a number of through holes, the through holes communicate with the expansion block 2, and the through holes are fixed with an airbag cushion 23 for sealing the through holes, the other end of the expansion adjustment rod 3 is connected to one end of the piston 22, and the piston 22 is provided with an air hole, the air ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com