A flower basket suitable for different sizes for wafer cleaning

A wafer and size technology, applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve problems such as production troubles and increase tooling costs, and achieve the effect of avoiding reserves and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

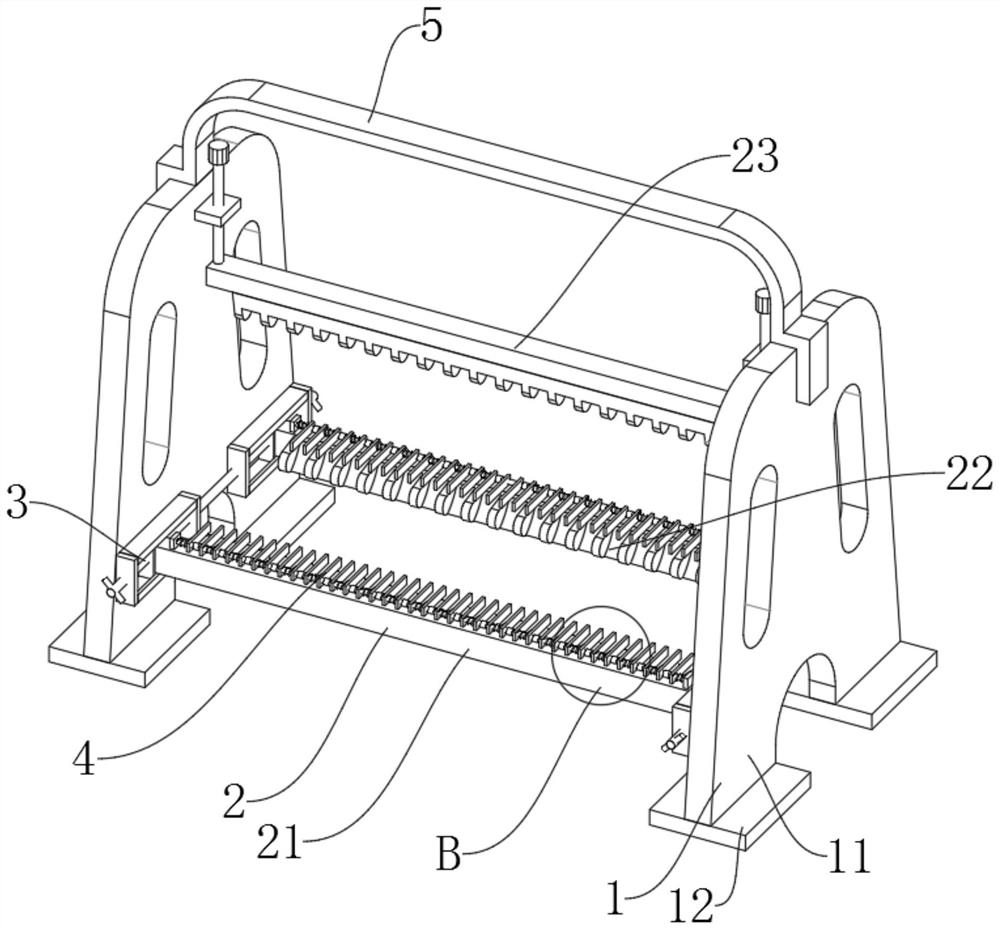

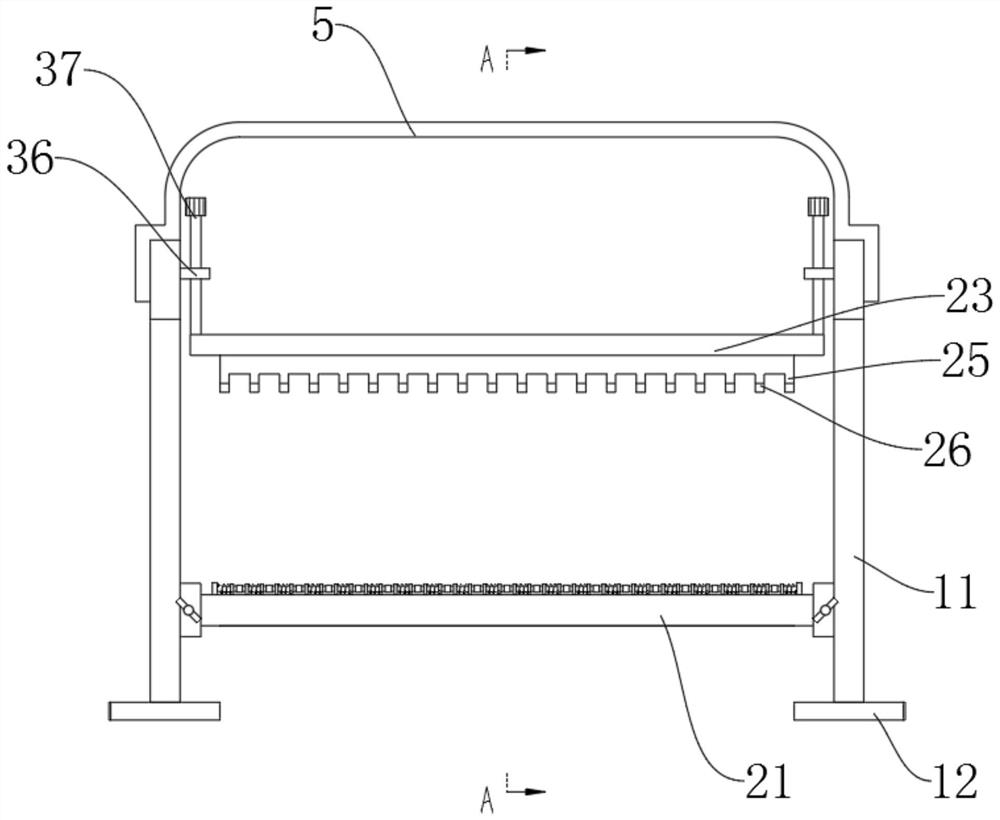

[0045] Such as Figure 1-Figure 7 As shown, a flower basket suitable for different sizes for wafer cleaning includes a supporting mechanism 1 and a limiting mechanism 2 arranged on the supporting mechanism 1 for limiting and supporting the wafer. On the limiting mechanism 2 A fixing mechanism 4 for fixing the placed wafer is provided, and an adjustment mechanism 3 for limit adjustment of the limit mechanism 2 is provided at both ends of the limit mechanism 2. The adjustment mechanism 3 is connected with the limit mechanism 2, and the limit mechanism 2 is connected with the fixing mechanism 4, and the adjustment mechanism 3 is connected with the support mechanism 1;

[0046] The support mechanism 1 includes vertical plates 11 arranged on both sides to support the whole. The lower end of the vertical plate 11 is provided with a bottom plate 12 to make the overall placement stable. The vertical plate 11 is provided with a process hole, and the upper end of the vertical plate 11 i...

Embodiment 2

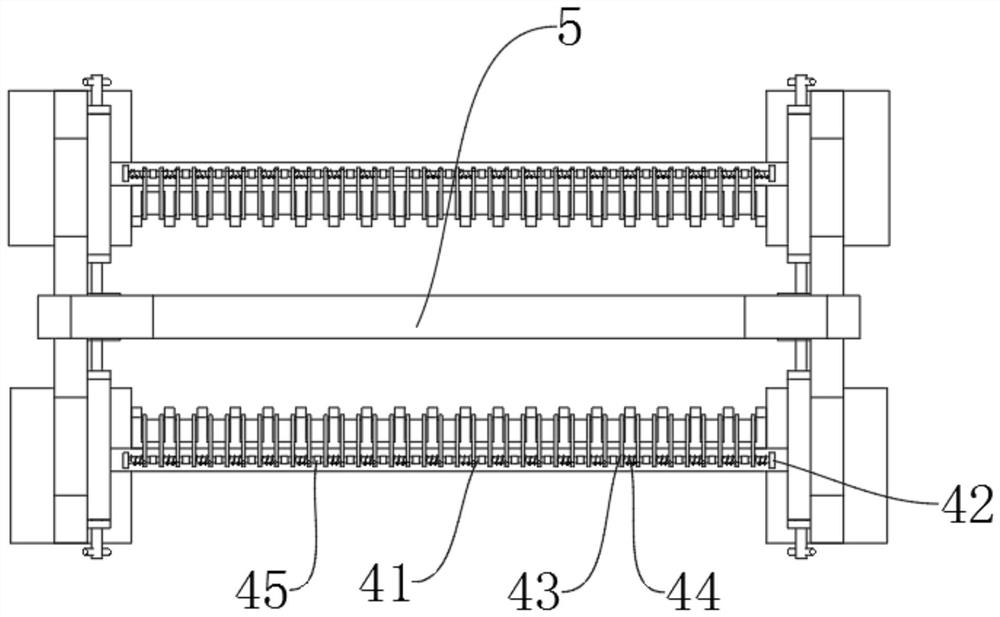

[0052] Such as Figure 5-Figure 8 As shown, a flower basket suitable for different sizes for wafer cleaning includes a supporting mechanism 1 and a limiting mechanism 2 arranged on the supporting mechanism 1 for limiting and supporting the wafer. On the limiting mechanism 2 A fixing mechanism 4 for fixing the placed wafer is provided, and an adjustment mechanism 3 for limit adjustment of the limit mechanism 2 is provided at both ends of the limit mechanism 2. The adjustment mechanism 3 is connected with the limit mechanism 2, and the limit mechanism 2 is connected with the fixing mechanism 4, and the adjustment mechanism 3 is connected with the support mechanism 1;

[0053] The support mechanism 1 includes vertical plates 11 arranged on both sides to support the whole. The lower end of the vertical plate 11 is provided with a bottom plate 12 to make the overall placement stable. The vertical plate 11 is provided with a process hole, and the upper end of the vertical plate 11 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com