Construction Method of Mechanism Model of Prestressed Anchor Cable Force Transmission when Anchor Section Crosses Double Strata

A technology of prestressed anchor cables and construction methods, which is applied in the field of geotechnical engineering, can solve the problems of unsteady damage, waste, and prestressed anchor cables that are no longer scientific and reasonable, so as to save engineering cost, reduce parameters, and promote green and sustainable construction. The effect of sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

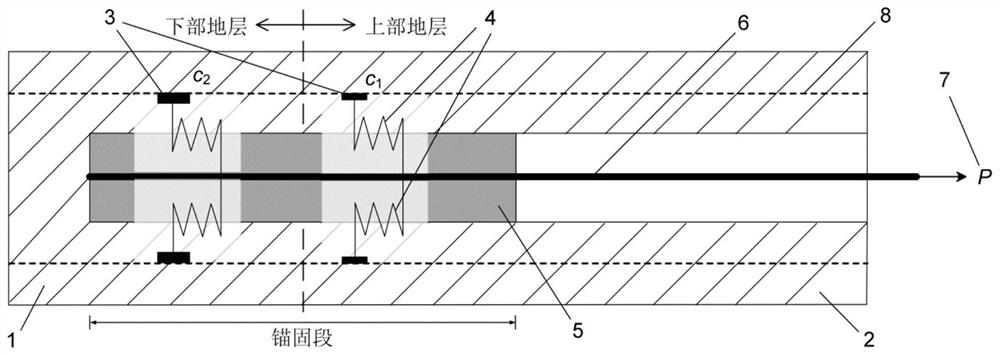

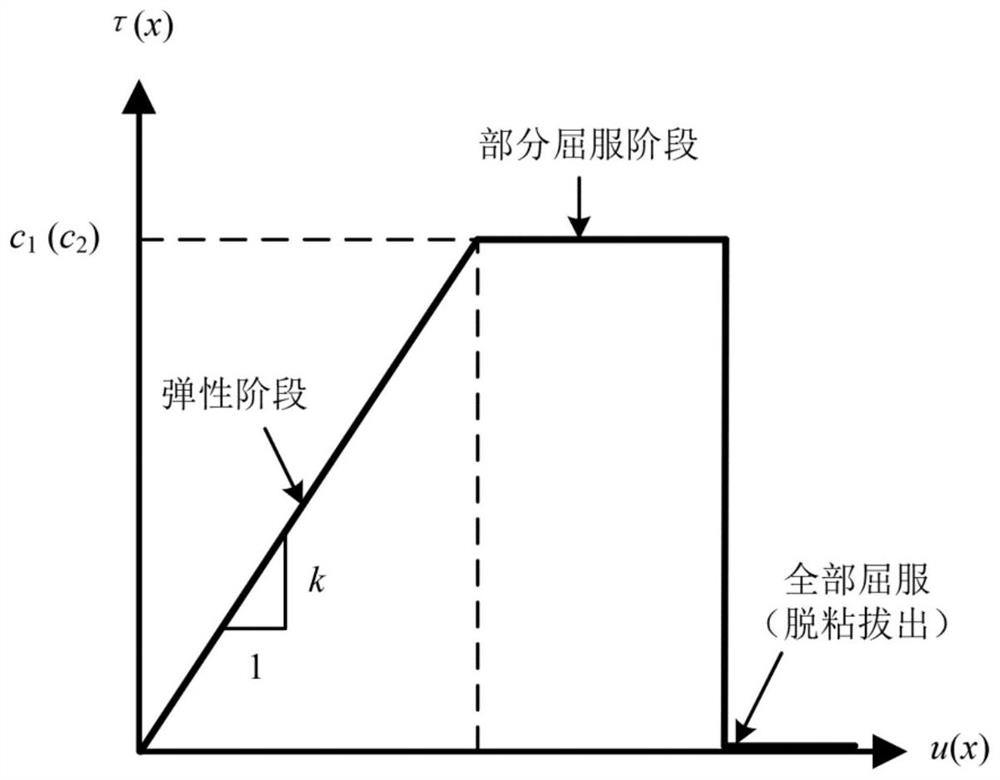

[0263] The background of the project on which this embodiment is based is as follows: Figure 10 As shown in the figure, the upper and lower strata traversed by the anchoring section of the prestressed anchor cable are the fine sand layer and the pebble layer, respectively, and the thickness of the fine sand layer and the pebble layer are 7m and 10m respectively; Segment length L 1 =13m, length L of anchoring section in pebble layer 2 = 9m, and other related parameters are shown in Table 1 and Table 2.

[0264] Relevant parameters of prestressed anchor cables in the embodiment of Table 1

[0265]

[0266] Soil layer parameters in the embodiment of table 2

[0267]

[0268] Step 1: Make rational assumptions about the actual working state of the prestressed anchor cable passing through the fine sand and pebble double formation in the anchoring section;

[0269] Step 1.1: Assume that there is a displacement interface parallel to the axial direction of the prestressed an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com