Verification device and method for load platform effect of self-expansion anchoring system

An anchoring system and verification device technology, applied in measurement devices, climate change adaptation, and the use of stable tension/pressure to test the strength of materials, etc. The effect of improving anchoring performance and improving observation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

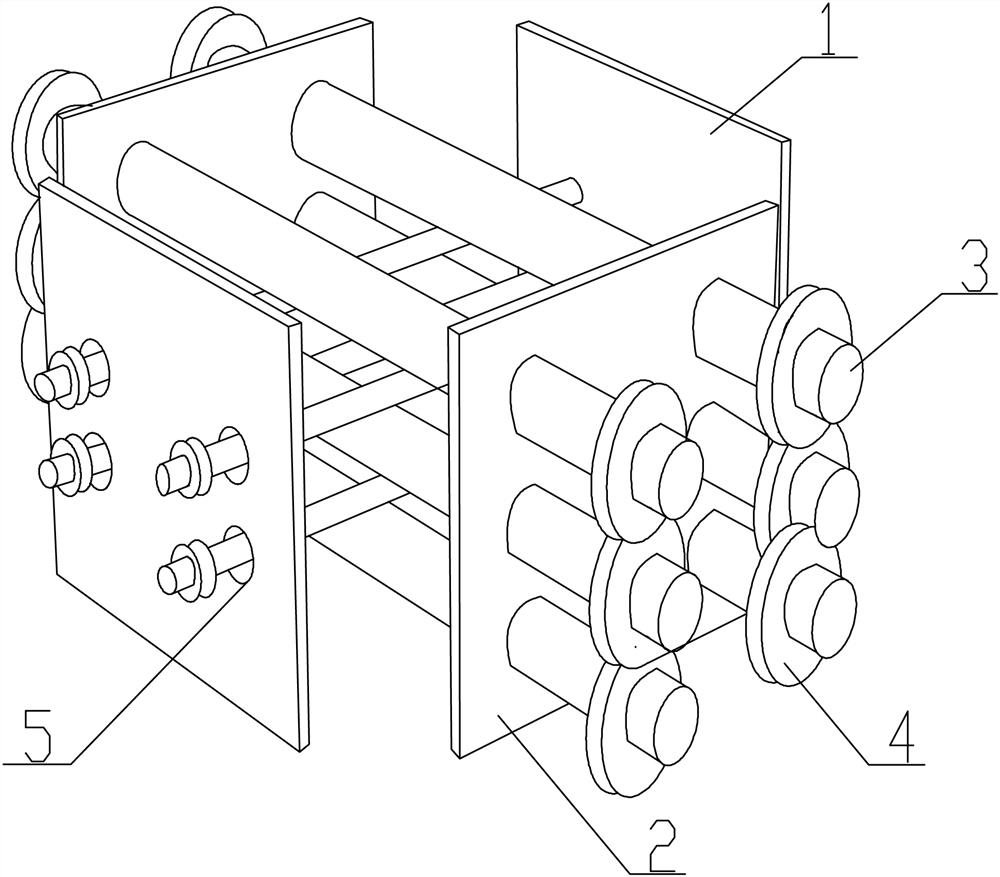

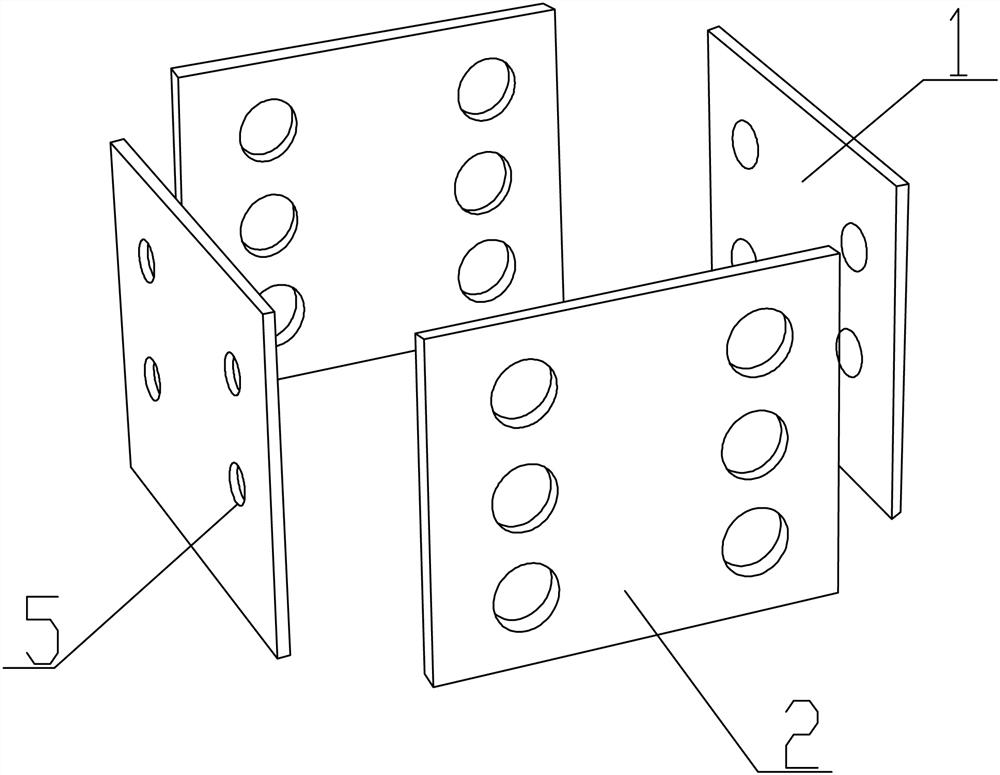

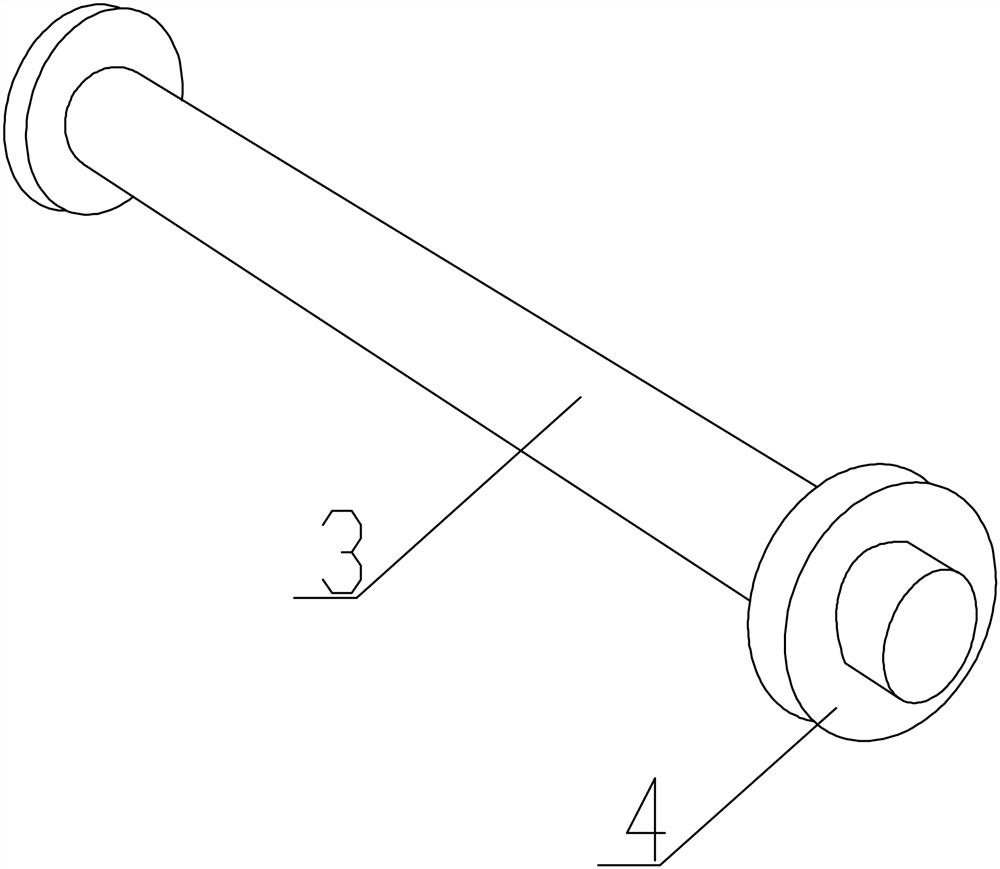

[0048] see Figure 1-9 , a verification device for the load platform effect of the self-expanding anchorage system, which includes two parallel first confining pressure splints 1 and two parallel second confining pressure splints 2; the first confining pressure splint 1 and the second confining pressure splint 2 are respectively processed with a plurality of evenly distributed threaded holes, and the first confining pressure splints 1 and the second confining pressure splints 2 arranged in pairs are fixedly connected by the threaded rods 3 and nuts 4 respectively, and the overall enclosing Form a box structure with an upper and lower roof; adjust the nut 4 to apply corresponding pressure to the device to simulate the real mountain slope surrounding rock pressure environment. By adopting the verification device of the above-mentioned device, the real mountain slope surrounding rock pressure environment can be simulated.

[0049] Further, the first confining pressure splint 1 a...

Embodiment 2

[0055] The verification device for the load platform effect of the self-expanding anchorage system is a test method for the load platform effect, including the following steps:

[0056] Step1: Make a corresponding mold according to the size of the rock sample 6 and pour the cement-based anchoring material, and at the same time add intermittent short fibers to it, stir the concrete to distribute the short fibers evenly, and wait for the material to solidify;

[0057] Step2: Using the impact rotary compaction drilling method, the impactor is installed at the bottom of the drill pipe, the impactor is equipped with a compaction drill bit, and the impact force of the impactor is used to drive the drill bit into the rock sample 6 during drilling;

[0058] Step3: First fix the second confining pressure splint 2 and the rock sample 6, pass the threaded rod 3 through the threaded holes of the front and rear splints and install the nut 4, and then assemble the first confining pressure sp...

Embodiment 3

[0069] Take the amount of expansion agent ω=10 as an example:

[0070] The verification device for the load platform effect of the self-expanding anchorage system is a test method for the load platform effect, including the following steps:

[0071] Step1: Make a corresponding mold according to the size of the rock sample and pour the cement-based anchoring material into it. At the same time, add an appropriate amount of intermittent short fiber material, stir the concrete to distribute the short fiber evenly, and wait for the material to solidify;

[0072] Step2: Using the impact rotary compaction drilling method, the impactor is installed at the bottom of the drill pipe. The impactor is equipped with a compact drill bit of a special shape. When drilling, the impact force of the impactor is used to drive the drill bit into the rock sample;

[0073] Step3: First fix the second confining pressure splint with the rock sample, pass the threaded rod through the threaded hole of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com