Ultrasonic thickness gauge and detection method thereof

A thickness gauge and ultrasonic technology, which is applied in the field of ultrasonic thickness gauge and its detection, can solve the problems of inconvenient storage of cables and probes, and achieve the effects of protecting the probe, stable storage, and preventing external wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following is attached Figure 1-4 The application is described in further detail.

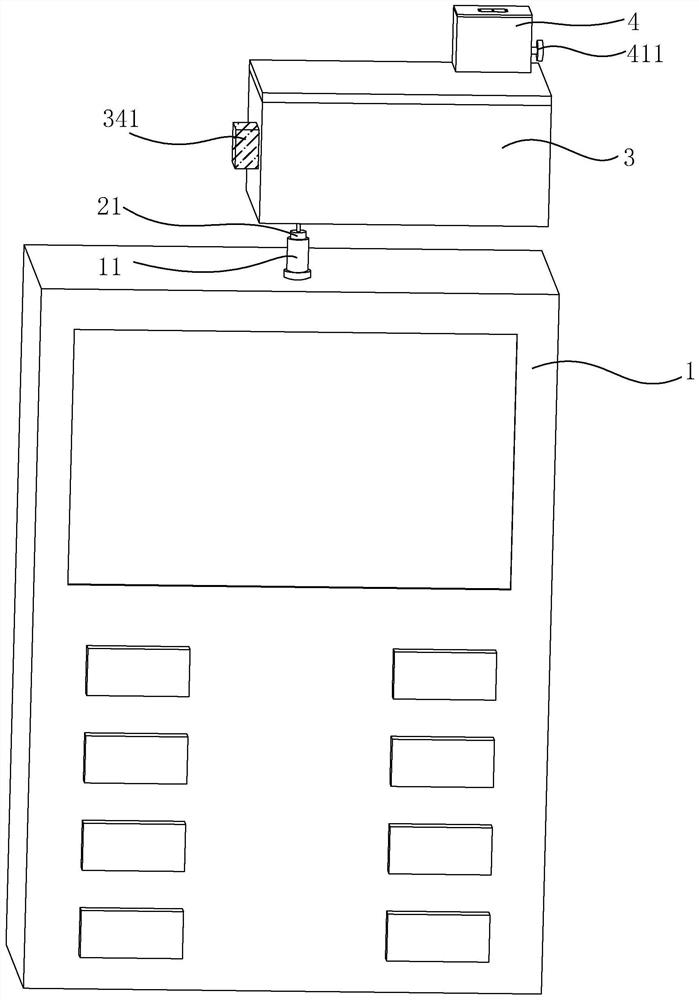

[0041] The embodiment of the present application discloses an ultrasonic thickness gauge. refer to figure 1 with figure 2The ultrasonic thickness gauge includes a thickness gauge body 1, a thickness gauge body 1 and a connecting wire 2, one end of the connecting wire 2 is coupled with a plug 21, the plug 21 is inserted into the socket 11, and the other end of the connecting wire 2 is coupled with a Probe 22; after use, place the probe 22 flat on the outer surface of the object to be measured coated with coupling agent, and then start the thickness gauge body 1 to measure the thickness of the object to be measured.

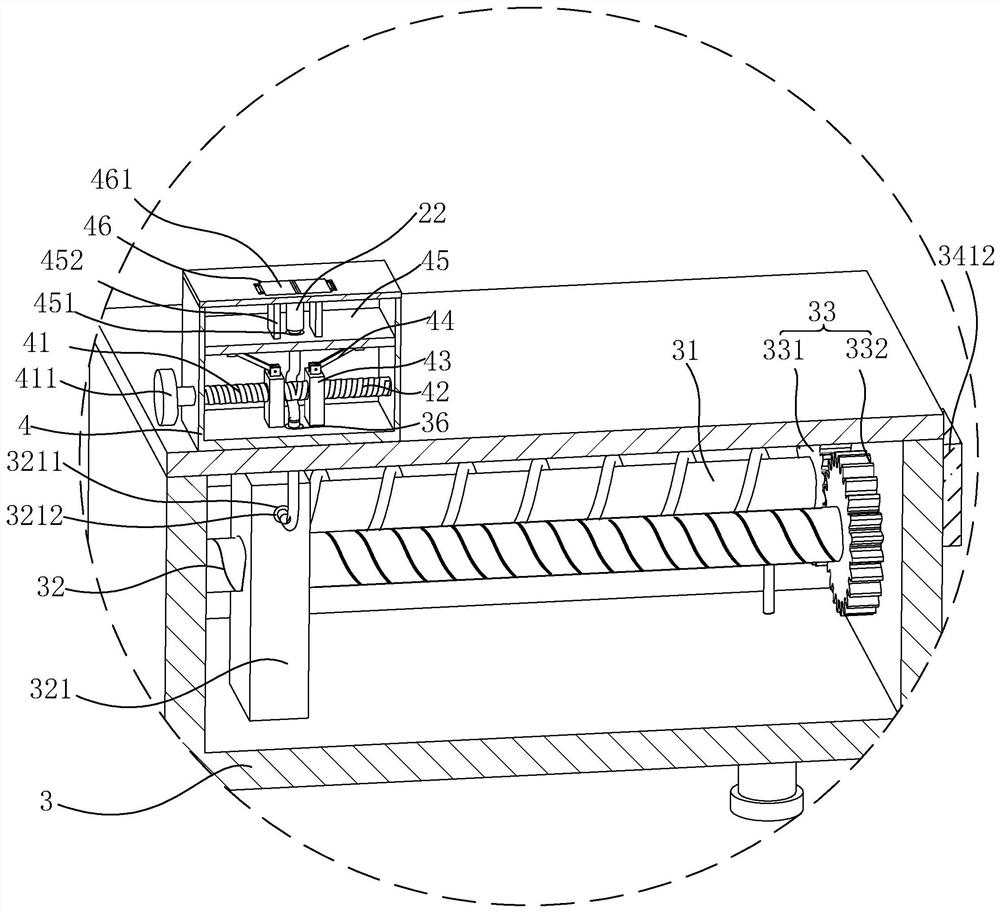

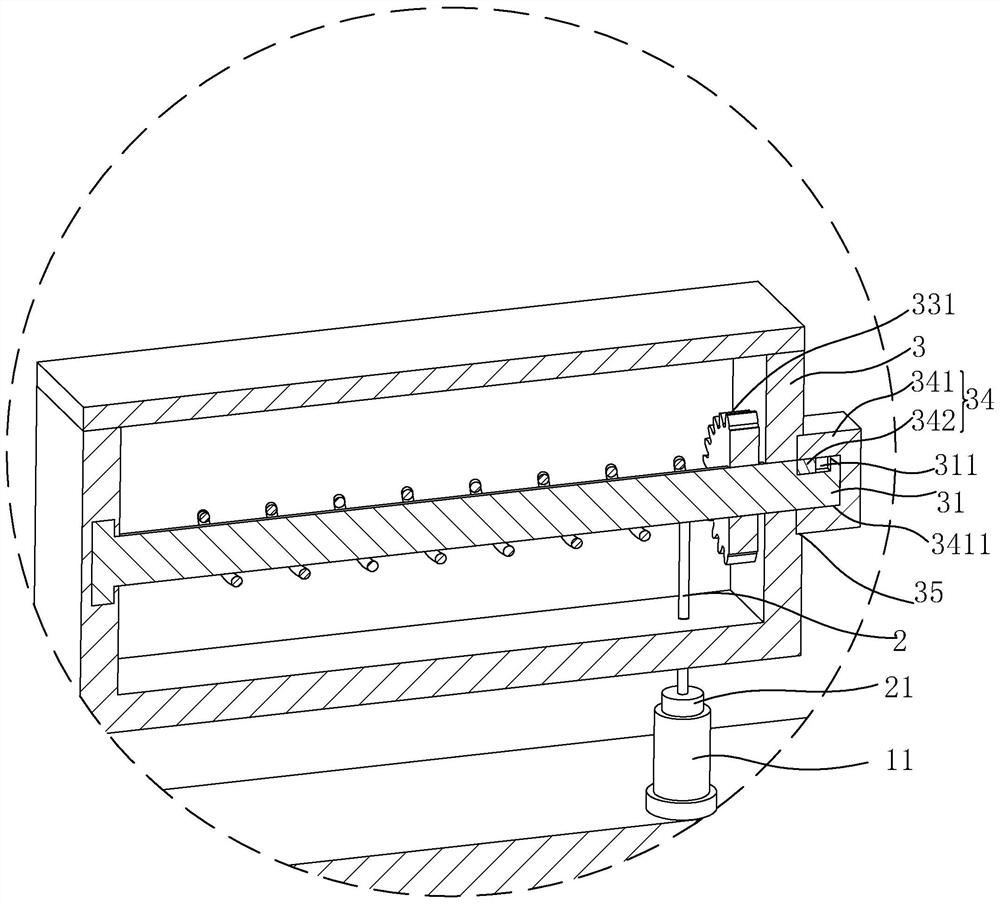

[0042] refer to figure 2 with image 3 , also includes a storage box 3, the inside of the storage box 3 is rotatably connected with a storage rod 31, and one end of the storage rod 31 runs through the end wall of the storage box 3, and the storage box 3 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com