Regenerator and refrigerating machine

A technology of regenerator and filling area, applied in refrigerators, refrigeration and liquefaction, compressors, etc., to achieve the effect of improving refrigeration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

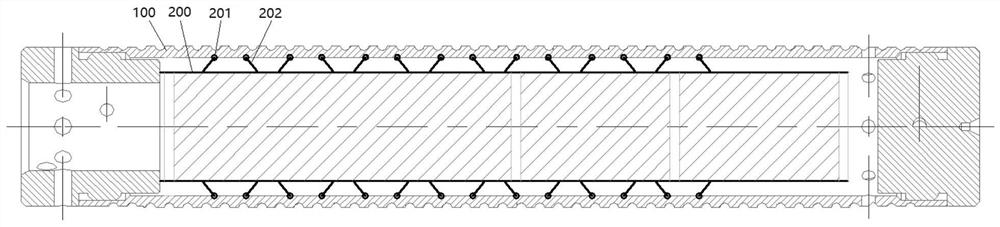

[0025] figure 1 A schematic cross-sectional structure diagram of a cool accumulator according to an embodiment of the present invention is shown.

[0026] The present invention provides a regenerator, including a heat exchange chamber, the heat exchange chamber is divided into a first filling area 101, a second filling area 102 and a third filling area 103 along the axial direction of the regenerator;

[0027] The first loading area 101 is filled with lead balls;

[0028] The second filling area 102 is filled with holmium copper balls and gadolinium oxysulfide balls, and the diameter of the holmium copper balls is smaller than the diameter of the gadolinium oxysulfide balls;

[0029] The third filling area 103 is filled with gadolinium oxysulfide balls.

[0030] Specifically, the factors affecting the heat storage and release of the regenerator include factors such as the heat capacity of the heat exchange particles inside the regenerator, the sum of the heat exchange surfac...

Embodiment 2

[0037] figure 2 A schematic cross-sectional structure diagram of a cool accumulator according to an embodiment of the present invention is shown.

[0038] On the basis of the first embodiment, in the embodiment of the present invention, a flow turbulence mechanism is added in the cold storage shell 100 .

[0039] Specifically, the heat exchange medium enters the heat exchange cavity from the heat exchange medium inlet, and the flow rate of the heat exchange medium near the axis of the heat exchange cavity is faster than that on both sides. The heat exchange between the heat medium and the gadolinium oxysulfide balls in the third packing area 103 is more efficient; the holmium copper balls are filled in the gaps in the second packing area 102, so that the fluid in the second packing area 102 can be reduced through the gap, which can be preliminarily Disperse the heat exchange medium to improve heat exchange efficiency; further, in order to reduce the flow velocity of the heat...

Embodiment 3

[0044] An embodiment of the present invention also provides a refrigerator, which includes one of the aforementioned cold accumulators.

[0045] To sum up, the embodiment of the present invention provides a regenerator and a refrigerator. The regenerator realizes external refrigeration sequentially through the multi-stage filling area, and the cooling efficiency can be improved by filling the gadolinium oxysulfide balls with holmium copper balls with smaller diameters; The addition of a turbulence mechanism can change the flow of the heat exchange medium in the heat exchange chamber, give full play to the heat exchange performance of the heat exchange medium in each area, improve heat exchange efficiency and avoid insufficient use of the heat exchange medium, and improve the performance of the cold storage unit. cooling efficiency.

[0046] By improving the composition and material of the heat exchange medium of the cold accumulator, the cooling efficiency per unit volume of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com