Plug-in type modular steel structure seismic mitigation and absorption connecting joint

A technology of connecting nodes and modularization, which is applied in the direction of earthquake resistance, building components, building structures, etc. It can solve the problems of long installation time, weak seismic performance at nodes, and small operating space, so as to improve the earthquake resistance and strong bending resistance , the effect of high prefabrication rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

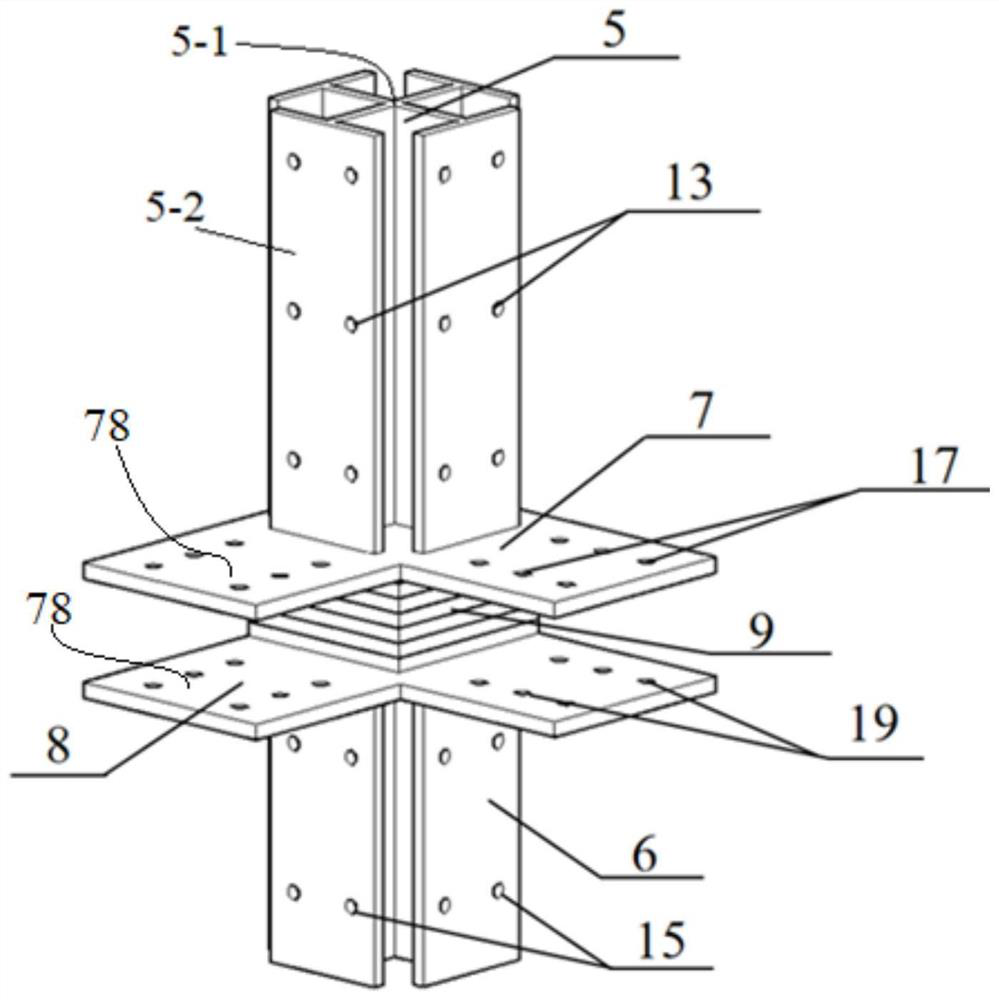

[0042] example, figure 1 It is a schematic diagram of the three-dimensional structure in the disassembled state of this embodiment, figure 2 It is a schematic diagram of the three-dimensional structure of this embodiment, image 3 It is a schematic diagram of the structure of the cross-shaped lead-core rubber shock-isolation bearing insert 21 in this embodiment, Figure 4 It is a schematic diagram of the lead-core rubber vibration-isolation bearing 12 of this embodiment. Specifically, such as Figure 1 to Figure 2 As shown, this embodiment provides a modular steel structure plug-in unilateral bolt connection node structure, including the upper steel pipe module column 1, the lower steel pipe module column 2, the upper H-shaped steel modular beam 3, the lower H-shaped steel modular beam 4, the upper side The cross-shaped insert 5, the lower cross-shaped insert 6, the upper sealing plate 7, the lower sealing plate 8 and the rubber steel plate damper 9, the upper and lower cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com