Full-automatic two-color sewing machine

A two-color machine, fully automatic technology, applied in the sewing unit, cloth feeding mechanism, cloth pressing mechanism, etc., can solve the problems of non-straight edges of garment pockets, low production efficiency, and only single-color sewing, so as to reduce the scrap rate , reduce waste, and solve the effect of single color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to further understand the content, features and effects of the present invention, the following examples are given and described in detail with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

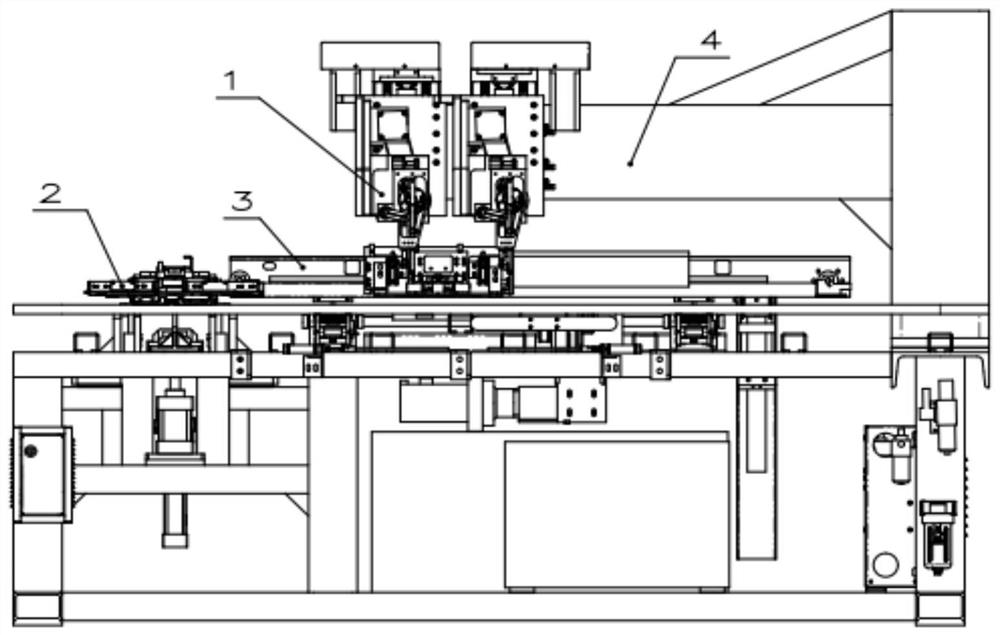

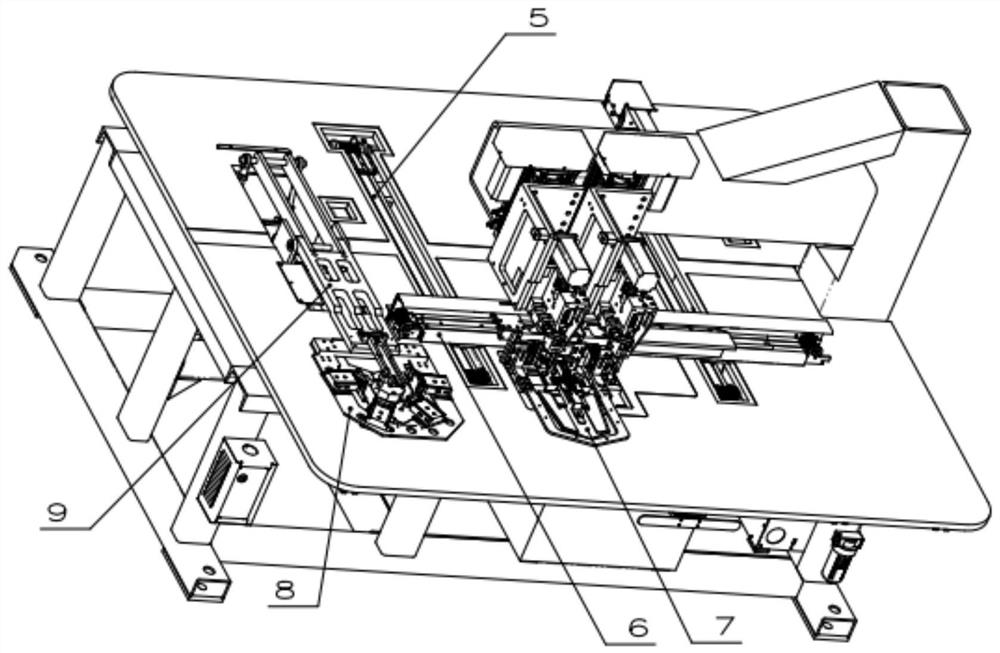

[0039] Fully automatic two-color machine, the whole machine includes: sewing mechanism (1), hemming mechanism (2), transmission mechanism (3), and machine frame (4).

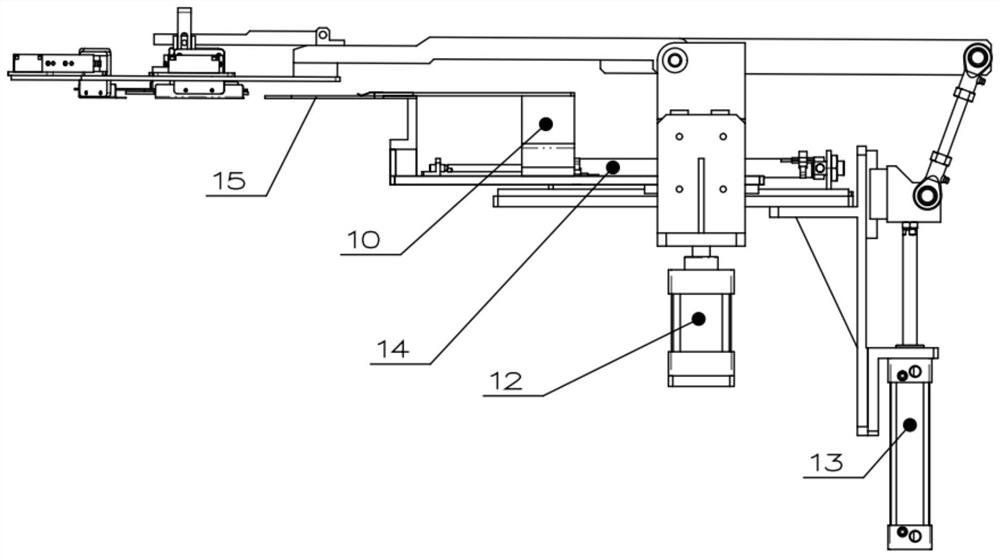

[0040] The cloth enters the hemming mechanism (2), and the formwork assembly (10) rises under the drive of the lifting cylinder (12). The large cloth is placed under the formwork (15), and the pocket fabric is placed above the formwork (15). Pushed by (13), the swivel arm assembly (9) drives the hemming assembly (8) and the cloth pressing plate (11) to fall, and the hemming shovel pushes the pocket edge fabric under the template (15) under the drive of the hemming cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com