Manipulator for precision part machining

A technology of parts and manipulators, which is applied in the field of manipulators for precision parts processing, can solve the problems of high gripping force of manipulators, low yield rate of precision parts, falling and breaking, etc., so as to save production costs and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

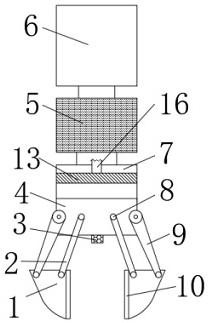

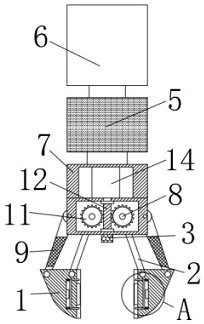

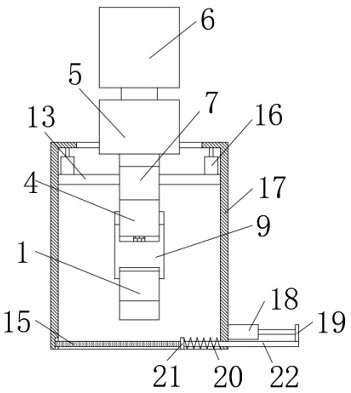

[0029] Such as Figure 1-6As shown, the embodiment of the present invention provides a manipulator for precision parts processing, including an upper housing 7, the lower end of the upper housing 7 is fixedly connected with a lower housing 4, and the middle parts of both sides of the lower housing 4 are connected by rotating shafts. At the upper end of the rotating rod 9, the lower end of the rotating rod 9 is connected to the outer side of the upper end of the finger 1 through a rotating shaft, and the inner side of the upper end of the finger 1 is connected to the lower end of the active rod 2 through a rotating shaft. 8 is rotatably connected to both sides of the middle part of the lower casing 4, the installation shaft 8 runs through the lower casing 4, the middle part of the installation shaft 8 is fixedly connected to the middle part of the turbine 11, and the inner side of the finger 1 is fixedly connected with an anti-slip rubber 10. When the manipulator grips and move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com