Rapid locating mechanism for stainless steel pipe production

A stainless steel tube and positioning mechanism technology, applied in positioning devices, metal processing machinery parts, clamping and other directions, can solve the problem that stainless steel tubes cannot be positioned quickly, and achieve the effects of convenient processing operation, simple operation and novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

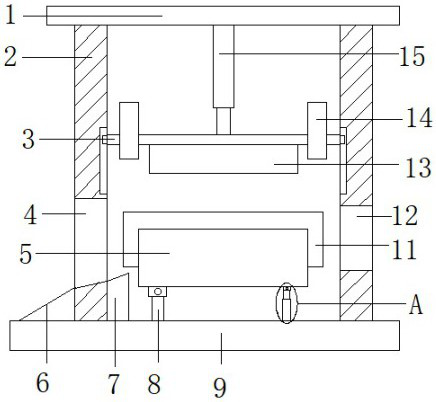

[0026] refer to Figure 1-3 : A quick positioning mechanism for the production of stainless steel pipes, including a base 9, the top of the base 9 is fixedly connected with two support arms 2 to support the internal parts, and the top of the two support arms 2 is fixedly connected with a crossbeam 1 , the bottom of the beam 1 is fixedly connected with a positioning structure, and the positioning structure includes a first push rod motor 15 fixedly connected to the bottom of the beam 1 to provide a power source for the positioning structure, and the output shaft of the first push rod motor 15 is fixedly connected with a connecting plate 3 The two sides of the connecting plate 3 are symmetrically welded with a processing device main body 14, which is convenient for processing the steel pipe 11, wherein the connecting plate 3 is connected with the first push rod motor 15 and the processing device main body 14, and the bottom of the connecting plate 3 is fixedly connected with a pr...

Embodiment 2

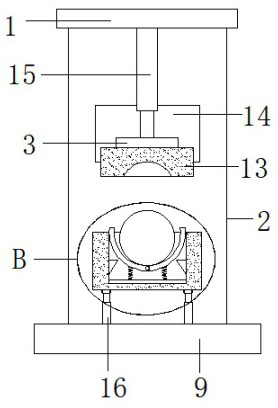

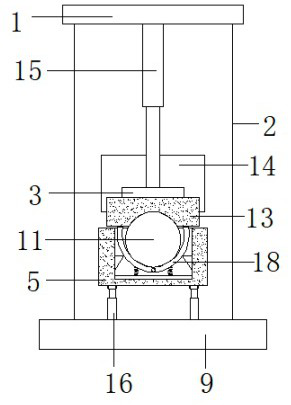

[0031] refer to Figure 2-6 : A quick positioning mechanism for stainless steel pipe production. In this embodiment, it includes a base 9. The top of the base 9 is fixedly connected with two support arms 2 to support the internal parts. The top of the two support arms 2 A crossbeam 1 is fixedly connected, and the bottom of the crossbeam 1 is fixedly connected with a positioning structure, which plays a role in quickly positioning the steel pipe. A discharge device fixedly connected to the top of the base 9 is provided below the positioning structure. The discharge device includes a fixed connection on the base Two support rods 8 on the left side of the top of the seat 9, the top of the support rod 8 is hinged with the operating table 5, the right bottom of the operating table 5 is fixedly connected with two hinged blocks 17, and the bottom of the hinged block 17 is hinged with two second Push rod motor 16, wherein support rod 8 and two second push rod motors 16 play a supporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com