Metal shell structure of implantable medical device and forming method

An implantable medical and metal shell technology is applied in the field of metal shell structure and forming of implantable medical devices, which can solve the problems of difficult welding process, low positioning accuracy, and difficult forming of barrier strips, and achieves improved anti-deformation. Capability, less positioning times, reducing the effect of poor assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be noted that the following embodiments are intended to facilitate the understanding of the present invention, but do not limit it in any way.

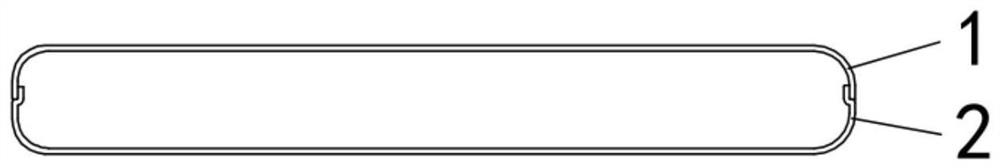

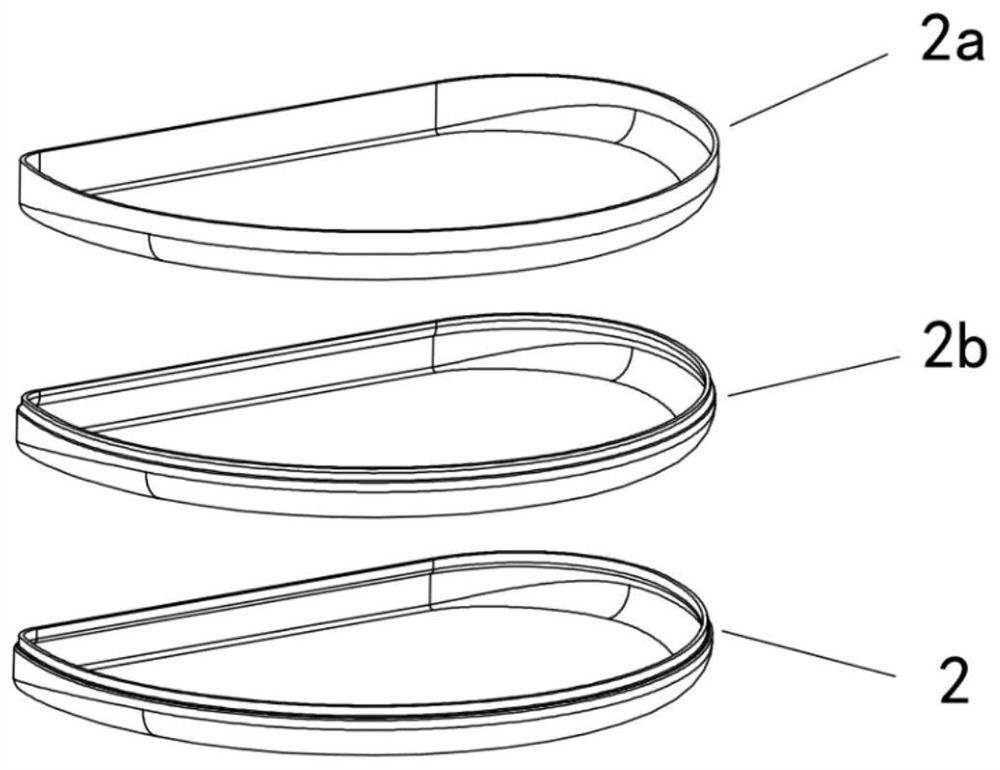

[0054] like Figure 1~2 As shown, a metal shell structure of an implantable medical device, according to the arrangement of components such as batteries and PCBA modules inside the shell, the outline of the shell is approximately semicircular and irregular. The shell is divided into an upper shell 1 and a lower shell 2. The upper shell 1 and the lower shell 2 are made of pure titanium or titanium alloy materials; the upper shell 1 and the lower shell 2 are made by stamping process; the upper shell The opening of the body 1 is approximately straight-sided, and the opening of the lower case 2 is in the shape of a protruding mouth that narrows toward the inside of the housing (hereinafter referred ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com