Automatic stamping facility for stainless steel outer retaining ring for fire-fighting metal hose

A metal hose and stamping equipment technology, which is applied in metal processing equipment, forming tools, feeding devices, etc., can solve the problems of size differences and inability to meet the welding process of fire-fighting metal hoses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

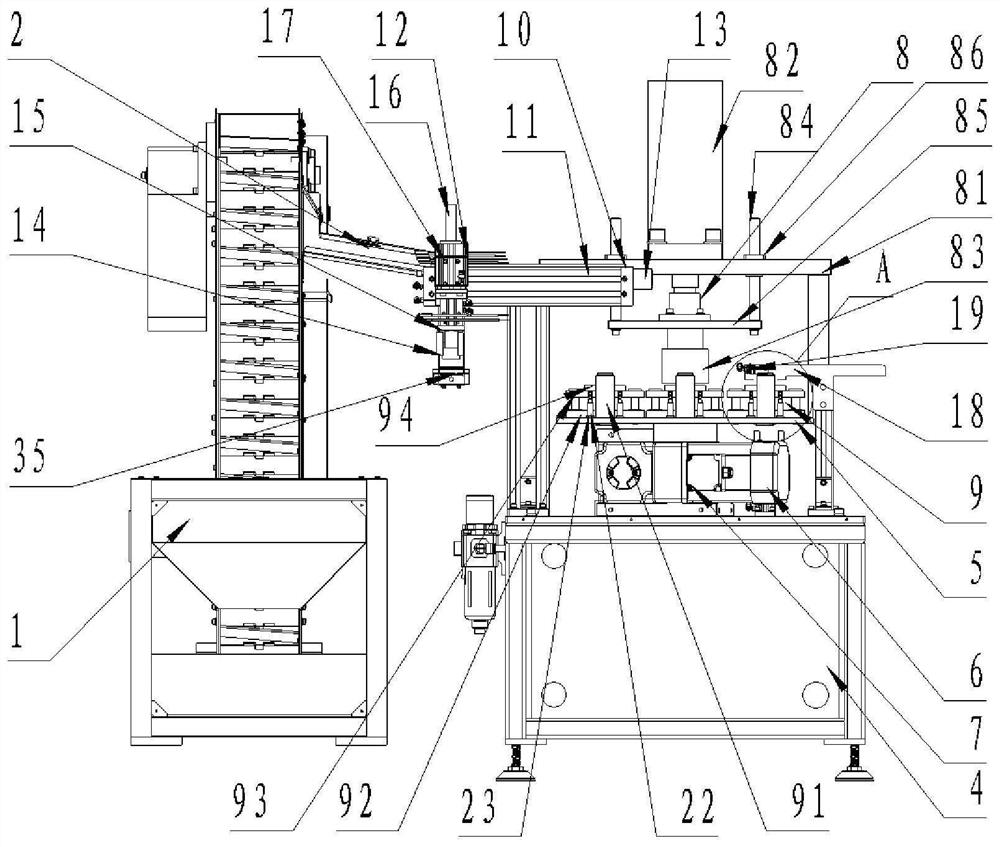

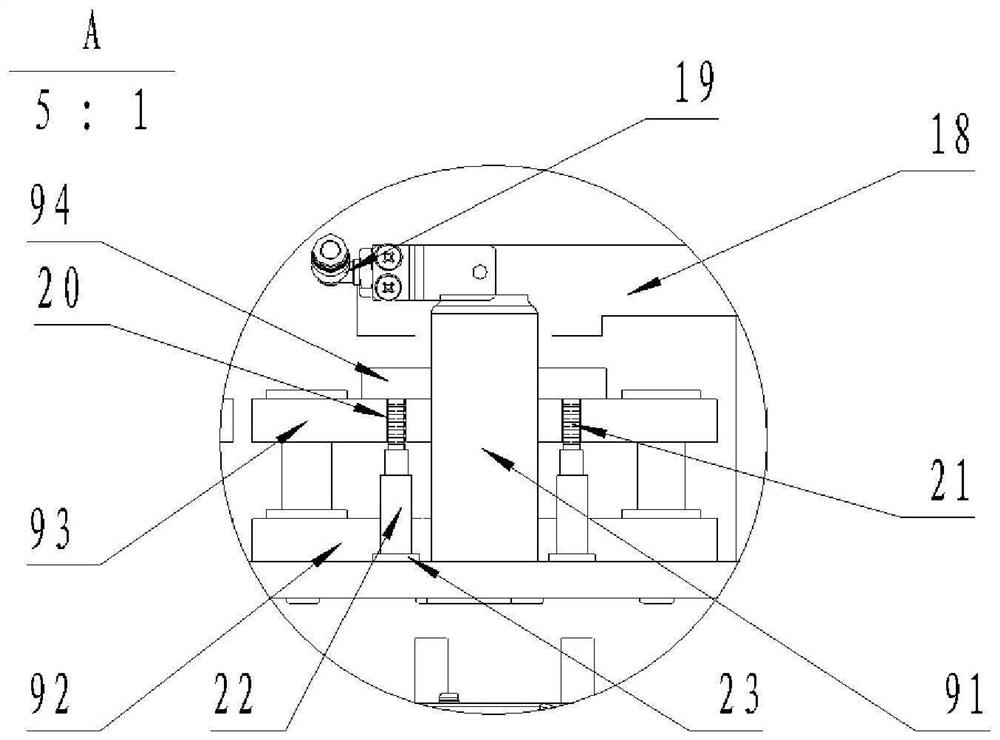

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, an automatic stamping equipment for stainless steel outer buckle for fire-fighting metal hoses, including a stainless steel outer buckle blank hoist 1 installed on a steel-concrete platform, and a stainless steel outer buckle blank hoist 1 with a discharge port , which is characterized in that: it also includes a restraint conveying device for stainless steel outer buckle blanks, a clamping and conveying device for stainless steel outer buckle blanks, and a stainless steel outer buckle installed on the steel-concrete platform on the right side of the stainless steel outer buckle blank hoist 1 Buckle blank stamping device (the observer faces the invention, the left side of the observer is the left side of the stainless steel outer buckle blank hoist, the right side of the observer is the right side of the stainless steel outer buckle blank hoist, close to the stainless steel outer buckle blank hoist. The si...

Embodiment 2

[0036] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, an automatic stamping equipment for stainless steel outer buckle for fire-fighting metal hoses, including a stainless steel outer buckle blank hoist 1 installed on a steel-concrete platform, and a stainless steel outer buckle blank hoist 1 with a discharge port , which is characterized in that: it also includes a restraint conveying device for stainless steel outer buckle blanks, a clamping and conveying device for stainless steel outer buckle blanks, and a stainless steel outer buckle installed on the steel-concrete platform on the right side of the stainless steel outer buckle blank hoist 1 Buckle blank stamping device (the observer faces the invention, the left side of the observer is the left side of the stainless steel outer buckle blank hoist, the right side of the observer is the right side of the stainless steel outer buckle blank hoist, close to the stainless steel outer buckle blank hoist. The si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com