Micro-fluidic chip for separating and enriching exosomes and manufacturing method of micro-fluidic chip

A microfluidic chip, separation and enrichment technology, applied in laboratory containers, chemical instruments and methods, biochemical equipment and methods, etc., can solve the problems of large consumption of sample reagents, long production time, low efficiency, etc. , to achieve the effect of reducing production cost and production time, low production cost and short capture time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

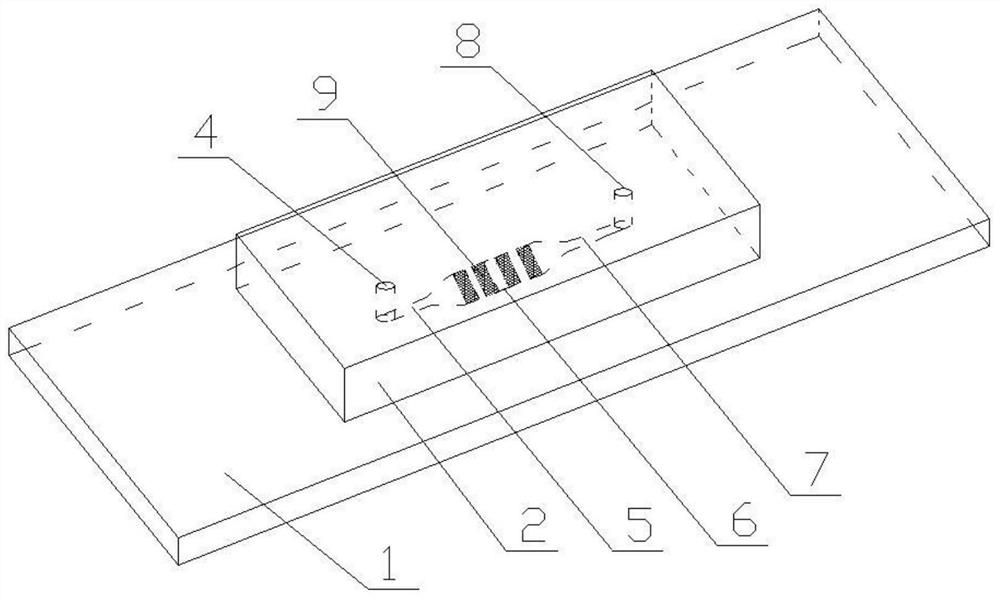

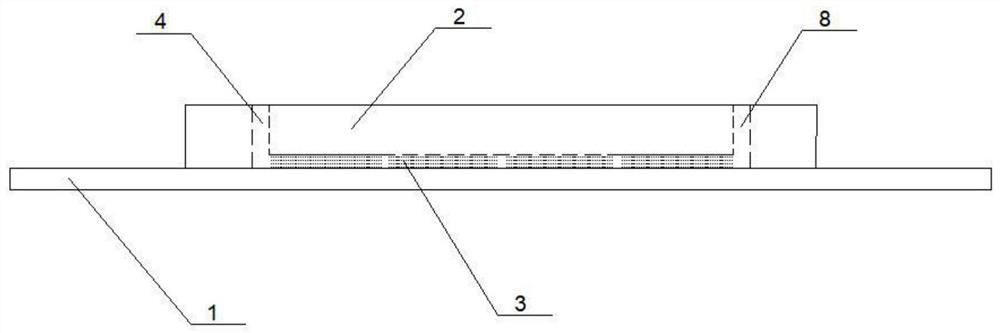

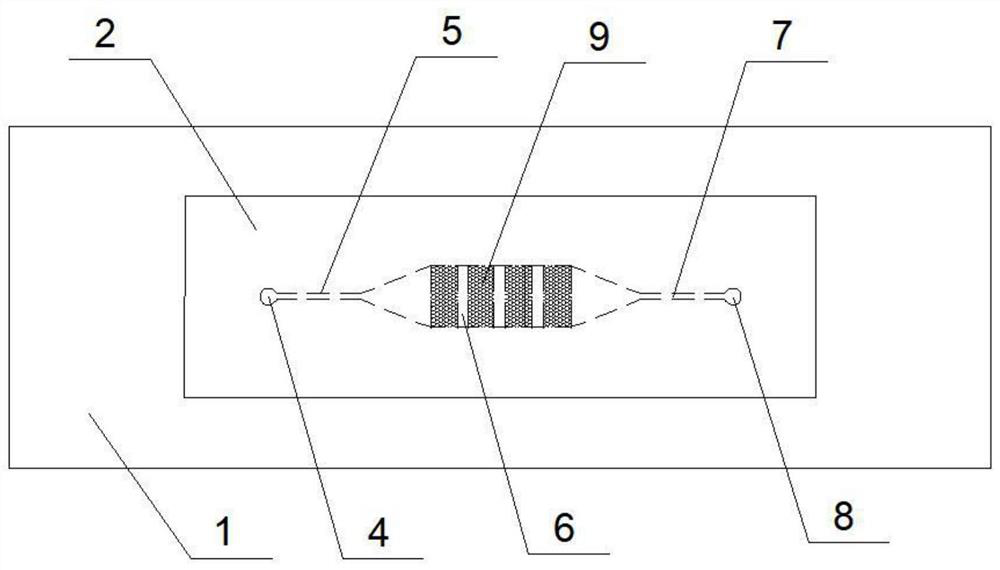

[0043] A microfluidic chip for separating and enriching exosomes, comprising a substrate with a three-dimensional porous structure bonded to a glass slide substrate, the substrate having a three-dimensional porous structure including microchannels arranged on the substrate, The microchannel is sequentially composed of a sample injection hole, a narrow channel one, a wide channel, a narrow channel two, and a sample outlet, and four three-dimensional porous regions with the same interval are arranged in the wide channel;

[0044] The pore area on the surface of the three-dimensional porous zone accounts for 21.6% of the total area of the three-dimensional porous zone, and the average pore diameter on the surface of the three-dimensional porous zone is 2.94 μm; the pore area of the cross-section of the three-dimensional porous zone accounts for 31.9% of the total area of the three-dimensional porous zone. %, the average pore diameter of the cross-section of the three-dimensi...

Embodiment 2

[0058] A microfluidic chip for separating and enriching exosomes, comprising a substrate with a three-dimensional porous structure bonded to a glass slide substrate, the substrate having a three-dimensional porous structure including microchannels arranged on the substrate, The microchannel is sequentially composed of a sample injection hole, a narrow channel one, a wide channel, a narrow channel two, and a sample outlet, and four three-dimensional porous regions with the same interval are arranged in the wide channel;

[0059] The pore area on the surface of the three-dimensional porous zone accounts for 21.6% of the total area of the three-dimensional porous zone, and the average pore diameter on the surface of the three-dimensional porous zone is 2.94 μm; the pore area of the cross-section of the three-dimensional porous zone accounts for 31.9% of the total area of the three-dimensional porous zone. %, the average pore diameter of the cross-section of the three-dimensi...

Embodiment 3

[0072] A microfluidic chip for separating and enriching exosomes, comprising a substrate with a three-dimensional porous structure bonded to a glass slide substrate, the substrate having a three-dimensional porous structure including microchannels arranged on the substrate, The microchannel is sequentially composed of a sample injection hole, a narrow channel one, a wide channel, a narrow channel two, and a sample outlet, and four three-dimensional porous regions with the same interval are arranged in the wide channel;

[0073]The pore area on the surface of the three-dimensional porous zone accounts for 21.6% of the total area of the three-dimensional porous zone, and the average pore diameter on the surface of the three-dimensional porous zone is 2.94 μm; the pore area of the cross-section of the three-dimensional porous zone accounts for 31.9% of the total area of the three-dimensional porous zone. %, the average pore diameter of the cross-section of the three-dimensio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com