Full-automatic inductance crochet needle machine

A fully automatic, crochet machine technology, applied in the field of crochet machines, can solve problems such as being unable to be fully automatic, and achieve the effect of improving production efficiency and saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

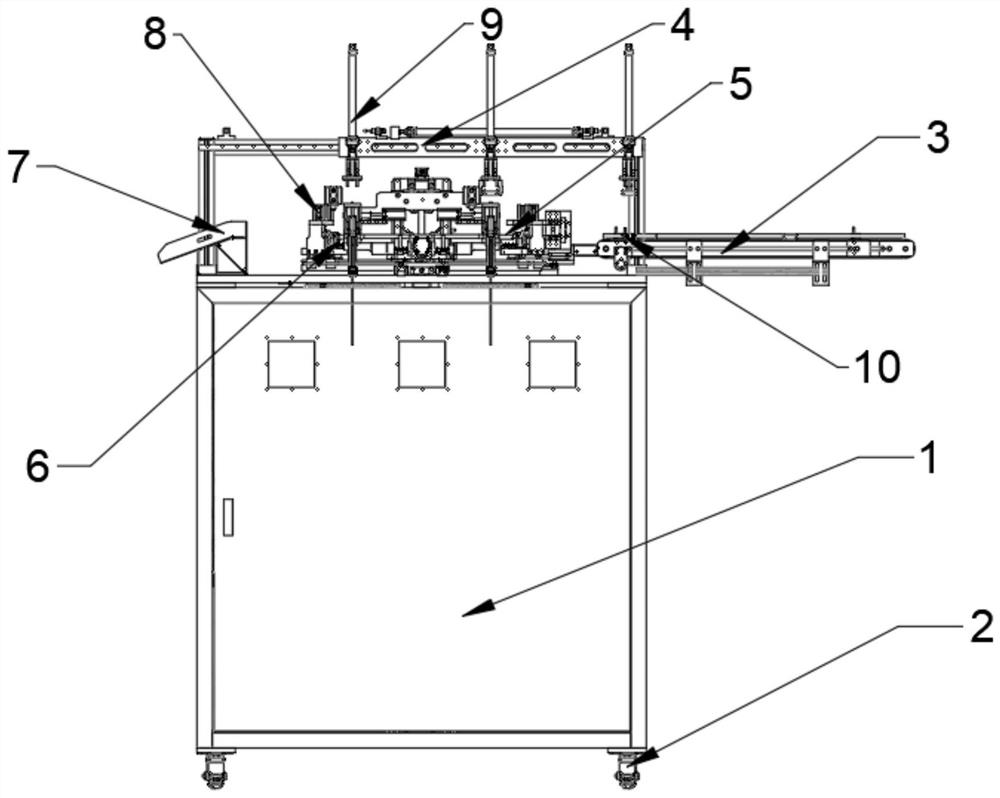

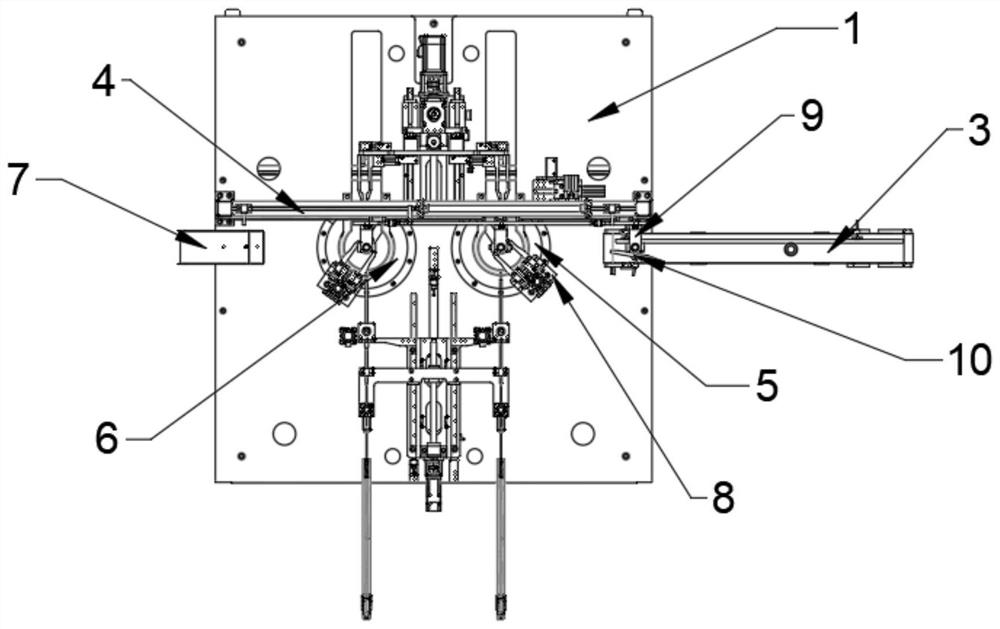

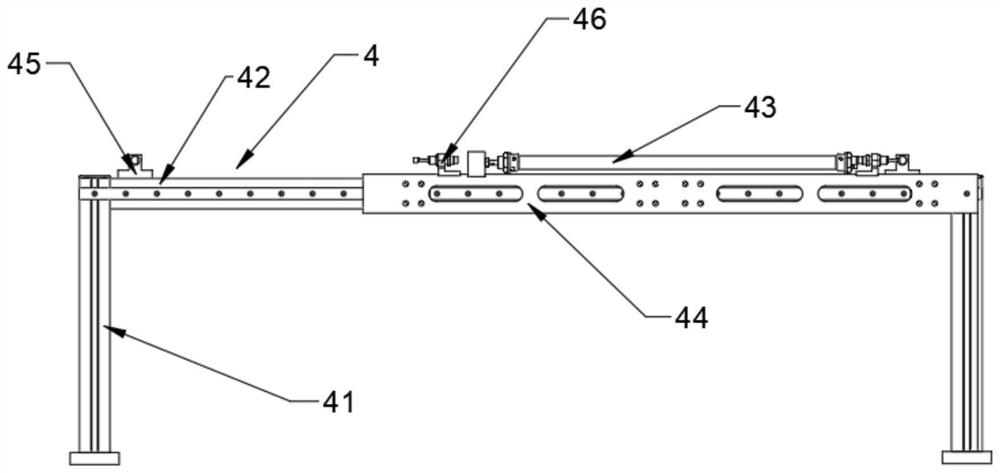

[0025] see Figure 1-5 , the present invention provides a technical solution: a fully automatic inductive crochet machine, including an electrical cabinet 1 and a synchronous belt line 3, an equidistant transport device 4 is installed above the electrical cabinet 1, and a transport fixture is installed on the front side of the equidistant transport device 4 9. The number of handling jigs 9 is three, and the three handling jigs 9 are arranged equidistantly. The lower end surfaces of the three handling jigs 9 are on the same plane, and the upper right side of the electrical cabinet 1 is installed with No. 1 winding equipment 5, and the electrical cabinet 1 The No. 2 winding device 6 is installed on the upper left side, and the No. 1 winding device 5 and the No. 2 winding device 6 are equipped with a compression device 8 above the outside. The compression device 8 includes a compression cylinder and a compression block. The electrical cabinet 1 The unloading device 7 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com