River power generation system

A power generation system, river technology, applied in hydropower, control system, engine components, etc., can solve the problems of generator power supply line damage, fast water flow, small potential energy difference, etc., and achieve the effect of preventing too fast transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

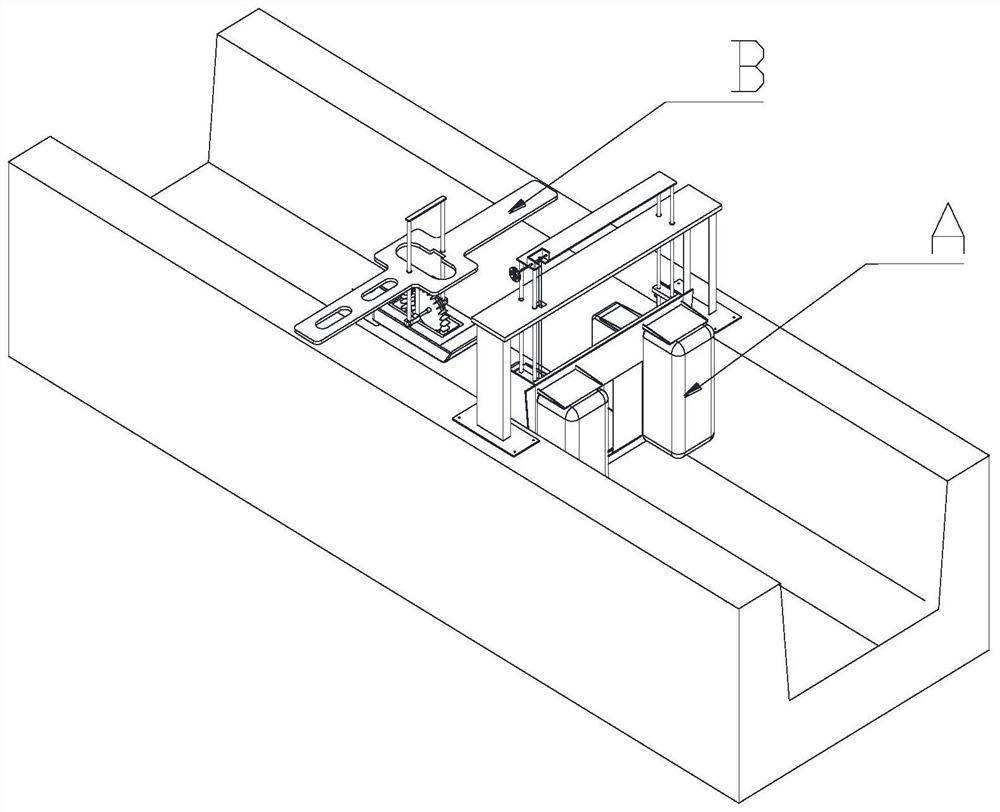

[0033] see Figure 1-Figure 11 , The river power generation system of the present invention includes a water blocking device A arranged in the upstream of the river and a power generation device B arranged in the downstream of the river.

[0034] (1), power generation device A

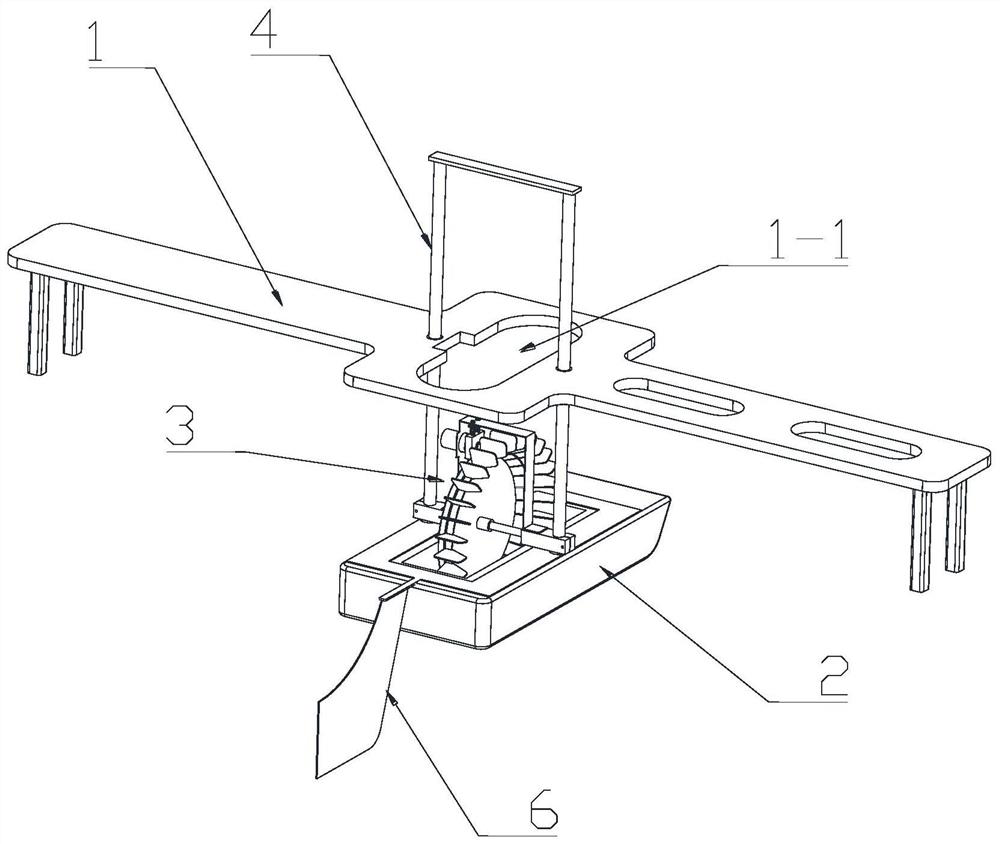

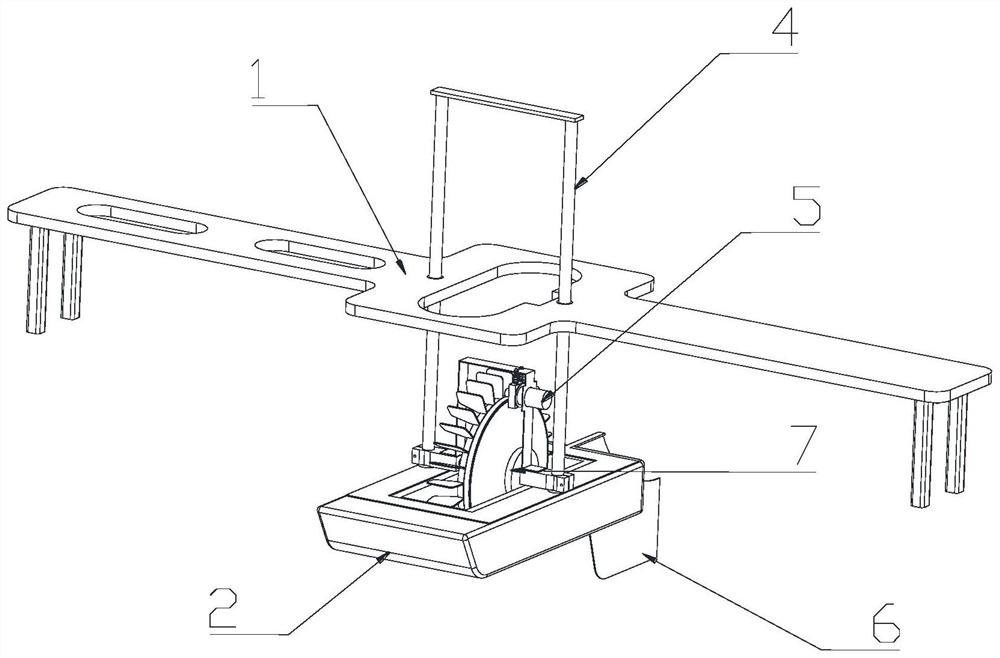

[0035] see Figure 1-Figure 11 , the power generation device straddles the first frame 1 on both sides of the river, the first suspension frame 2 arranged below the first frame 1 , and the power generation module 3 arranged on the first suspension frame 2 .

[0036] see Figure 1-Figure 11, the first suspension frame 2 is made of foam material, and is installed on the first frame 1 through the first vertical guide mechanism 4, and the first frame 1 is in the second position with the power generation module 3 An avoidance groove 1-1; the first vertical guide mechanism 4 is two groups, and each group of first vertical guide mechanism 4 includes a guide hole arranged on the first frame 1 and a guide ho...

Embodiment 2

[0053] see Figure 12 The difference between this embodiment and Embodiment 1 is that the water blocking device includes a second frame 11, a second suspension frame 12, and a water blocking mechanism arranged on the second suspension frame 12, wherein the water blocking device The water mechanism includes a first baffle plate 13, a second baffle plate 14, and a water baffle for driving the first baffle plate 13 and the second baffle plate 14 to move toward each other or reversely to open or close the water inlet. Drive mechanism, wherein, the second frame 11 spans both sides of the river; the second suspension frame 12 is installed on both sides of the river, and is located on the inner side of the river, the first baffle plate 13 and The second baffle 14 is located on both sides of the river, and is respectively rotatably connected to the second suspension frame 12; so that the first baffle 13 and the second baffle 14 can rotate in the vertical direction, thereby controlling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com