Telescopic material distributing machine

A kind of material distribution machine and telescopic technology, which is applied in shaft lining, tunnel lining, underground chamber, etc., can solve the problems of lateral force influence, large pressure loss, and many elbows, so as to achieve reasonable overall force and connect pipelines The effect of fewer bends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

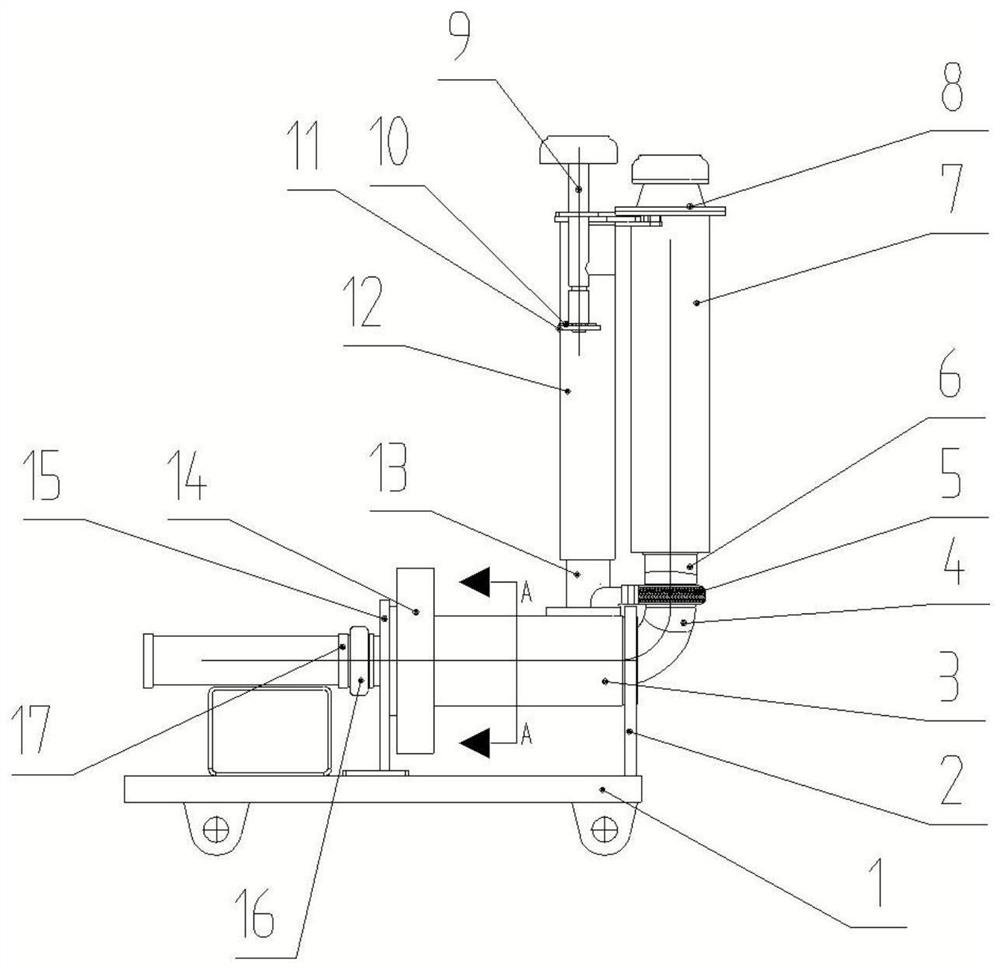

[0035] see Figure 1-5 , a telescopic distribution machine, comprising a track trolley 1, a rotating mechanism, a pouring port assembly and a cleaning port assembly, the cleaning port assembly includes a telescopic assembly and a cleaning pipe group, and the cleaning pipe group is arranged on the telescopic assembly On the rotating mechanism, the pouring port assembly includes a telescopic sleeve, the telescopic sleeve is movably connected with the telescopic assembly, and the telescopic assembly is used to drive the cleaning pipe group and the telescopic sleeve to move, and the rotating mechanism is arranged on On the track trolley 1, the rotating mechanism is used to drive the pouring port assembly and the cleaning port assembly to rotate, thereby realizing the function of rotating the cloth.

[0036] see figure 1 , the rotation mechanism includes a rotation support cylinder 3 and a rotation drive member 14, the rail trolley 1 is provided with a first support seat 2 and a s...

Embodiment 2

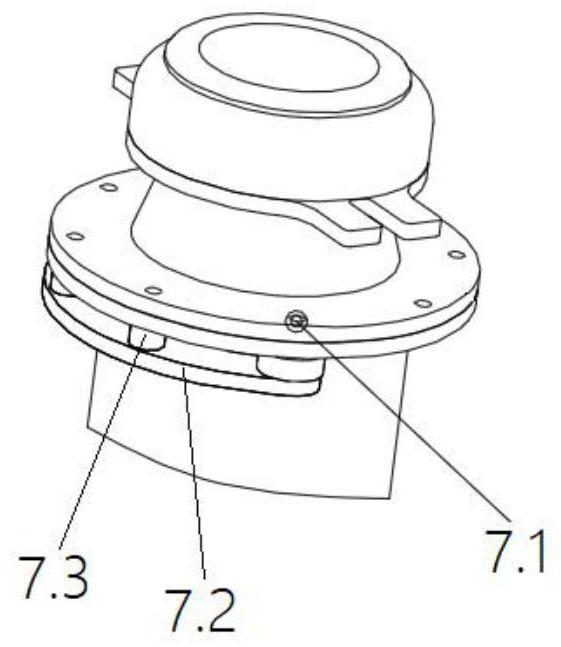

[0050] The difference between this embodiment and Embodiment 1 is that the first pipe clamp only includes a pipe clamp seat and a flexible sealing ring, and the fixed connection between the pouring mouth assembly and the rotating mechanism is realized by directly fixing the rotating support cylinder and the straight pipe. , specifically: the rotating support cylinder 3 is evenly distributed along the circumferential direction with a plurality of clamping mechanisms, and the curved straight pipe 4 is clamped by the clamping mechanisms, such as Figure 6 shown.

[0051] The clamping mechanism includes an adjusting bolt 3.1 and a pressing block 3.2. The rotating support cylinder 3 is provided with a threaded hole matching the adjusting bolt 3.1. The pressing block 3.2 is arranged at the end of the adjusting bolt 3.1 and is located Inside of barrel 3. The straight pipe is located inside the rotating support cylinder 3, and the straight pipe is compressed by the pressing block by ...

Embodiment 3

[0053] The difference between this embodiment and Embodiment 1 is that the first pipe clamp only includes a pipe clamp seat and a flexible sealing ring, and the fixed connection between the pouring mouth assembly and the rotating mechanism is realized by directly fixing the rotating support cylinder and the straight pipe. , specifically: the rotating support tube 3 is provided with a fixed plate 3.3, and the straight pipe 4 is provided with a mounting plate 4.1, and the fixed plate 3.3 and the mounting plate 4.1 are connected by a locking bolt 3.4, thereby realizing The pouring gate assembly is fixedly connected with the rotating mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com