Particulate floatation device

A flotation device and particle technology, which is applied in the direction of flotation water/sewage treatment, etc., can solve the problems of increased equipment use, high energy consumption, short service life, etc., to save product cost, save connection pipes, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

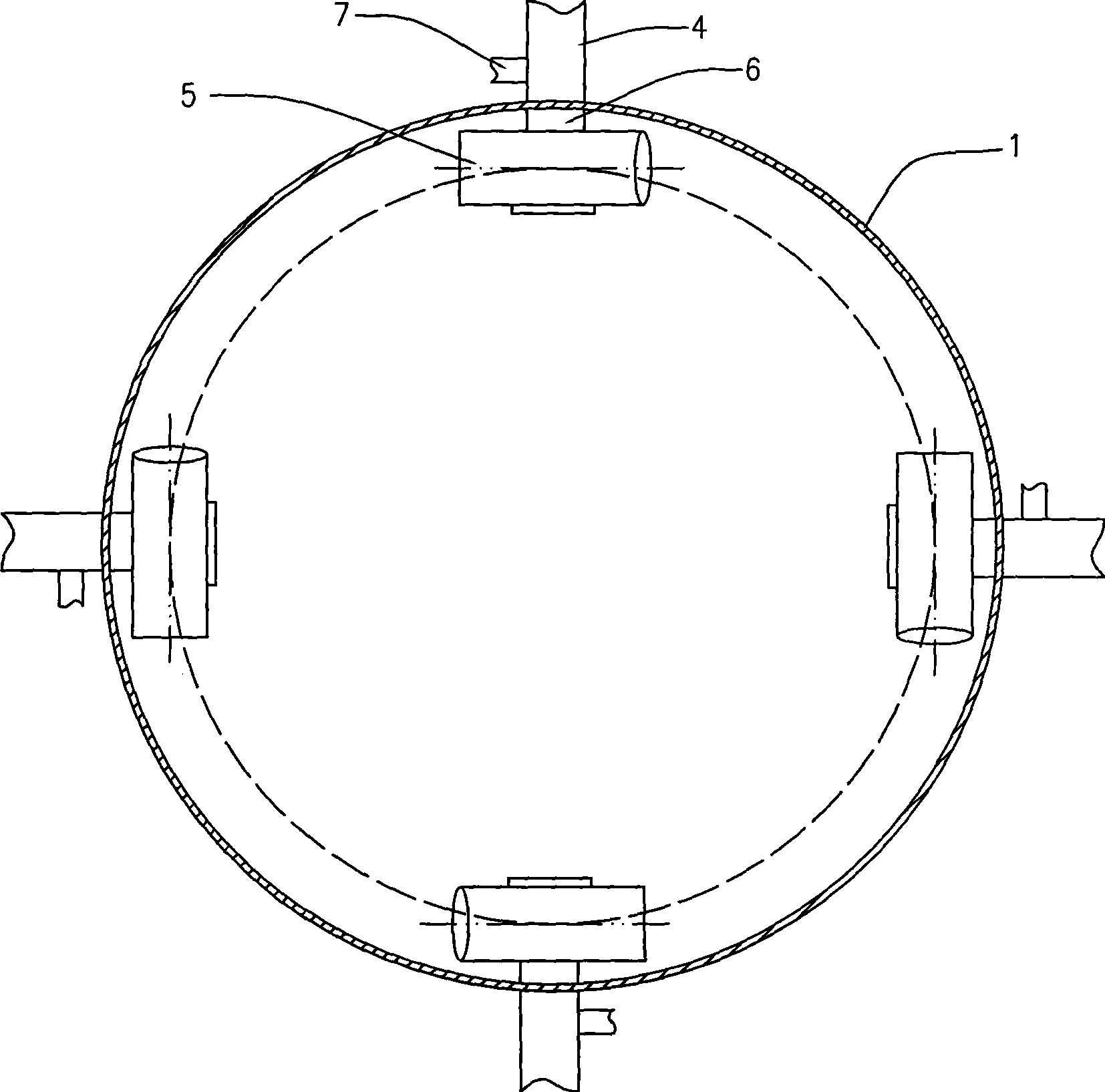

[0020] figure 1 , 2 As shown, the particle flotation device of the present invention is made of tank body 1, Roots blower 9, gas-liquid mixing device, multifaceted hollow ball 8 and clear water drain pipe, the bottom of tank body 1 is barrel-shaped, and the top is conical, The upper and lower ends of the barrel-shaped part are respectively provided with a sewage water inlet 2 and a clear water discharge outlet, and a slag discharge port 3 is provided at the sharp corner of the conical part, and a valve is installed at the slag discharge port 3, and the slag discharge port is passed through the slag discharge port. 3 Discharge slag outward.

[0021] figure 2 It is shown that two pairs of gas-liquid mixing devices are radially symmetrically arranged at the inner bottom of the tank body 1, see further image 3 , 4 , each gas-liquid mixing device is composed of a gas-liquid mixing pipe 5, a drain pipe 6 and an air inlet pipe 7, wherein the gas-liquid mixing pipe 5 is vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com