Double-steel-plate shear wall internally provided with replaceable inclined struts and construction method of double-steel-plate shear wall

A double-steel plate and shear wall technology, which is applied to walls, building components, and earthquake resistance, can solve problems such as insufficient connection between steel plates and surrounding section steel, insufficient wall bearing capacity, and poor deformation and energy consumption, etc., to achieve space occupation Small size, light weight, high bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

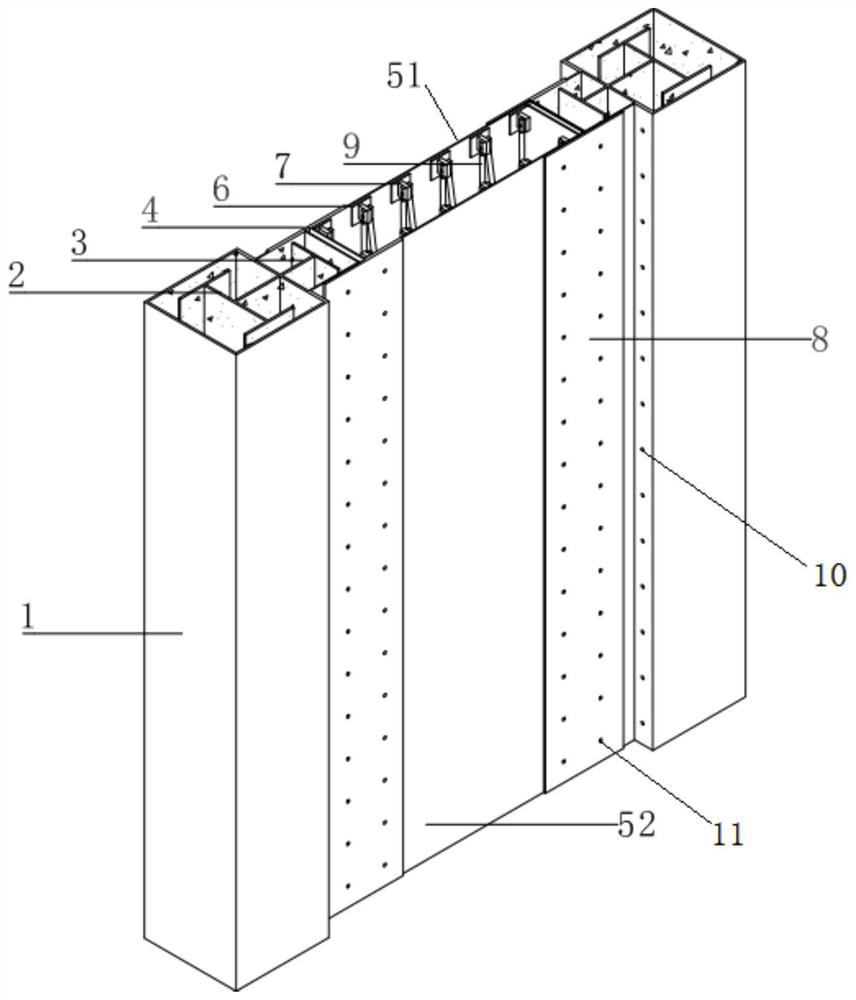

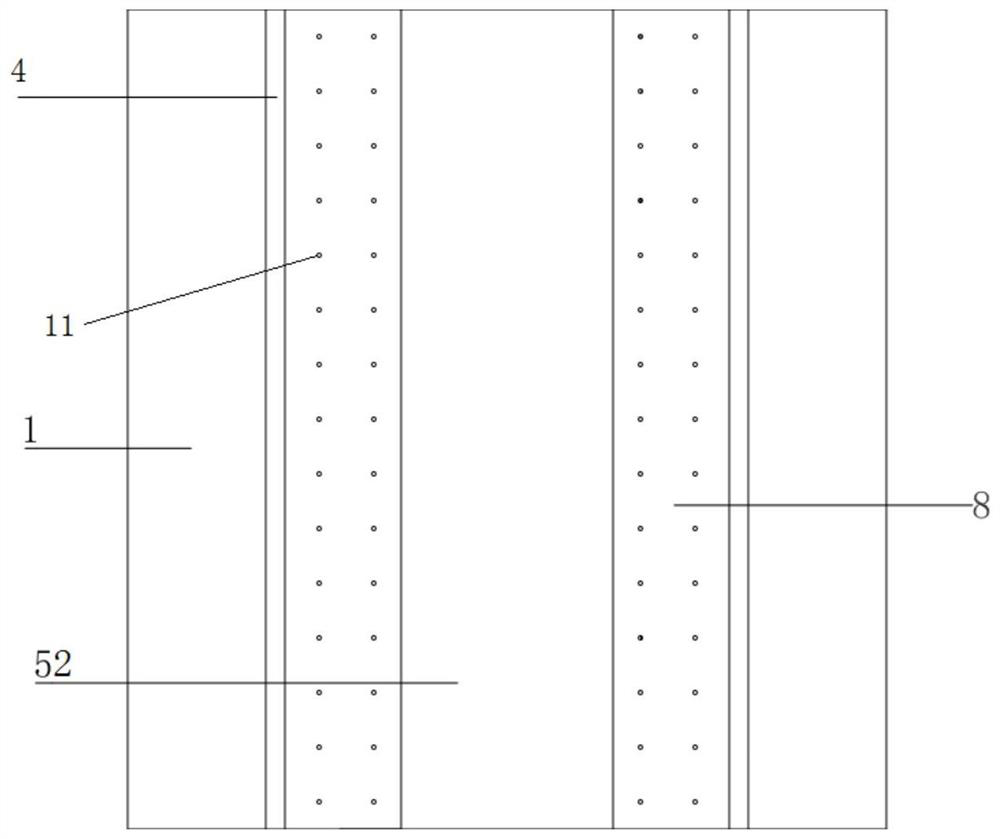

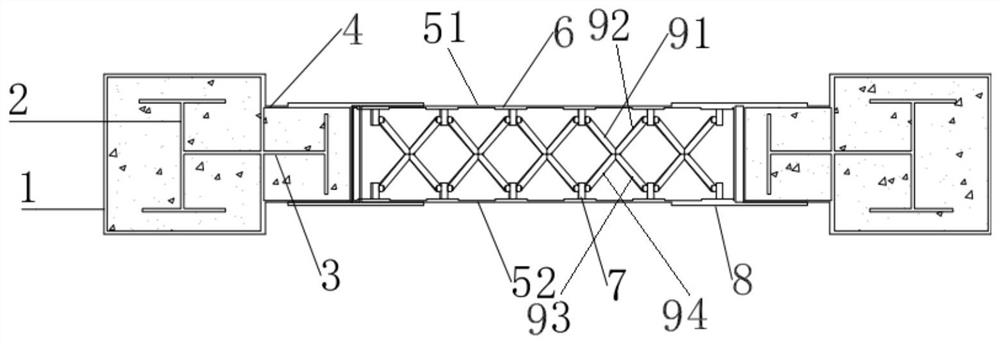

[0032] The present invention is a double-steel plate shear wall with replaceable diagonal bracing inside, such as figure 1 , figure 2 , image 3 and Figure 5 As shown, it includes a first steel column 1 , a second steel column 4 , a first steel plate 51 , a second steel plate 52 , a connector 7 , a first steel tube 91 , a second steel tube 92 , a third steel tube 93 and a fourth steel tube 94 .

[0033] There are two first steel columns 1, and the two first steel columns 1 with the same shape are arranged parallel and flush. Between the two first steel columns 1, there are fixedly connected the first steel plate 51 and the second steel column 51 arranged in parallel along the length direction thereof. Two steel plates 52, the width formed between the first steel plate 51 and the second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com