Wallboard butt joint assembly and assembly type wall surface system

A technology of docking components and docking surfaces, which is applied to walls, building components, buildings, etc., can solve the problems of dependence on construction effects, poor appearance quality, and difficulty in secondary utilization of wall panel units, so as to achieve simple, convenient and strong disassembly and maintenance. Waterproof performance, the effect of the best appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

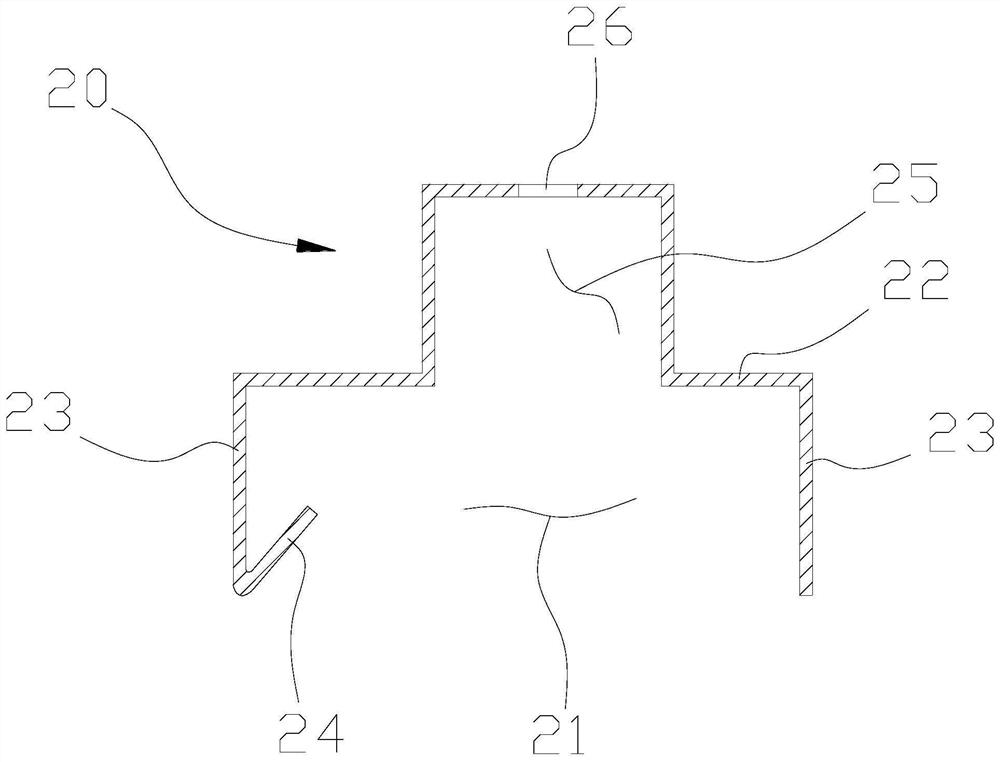

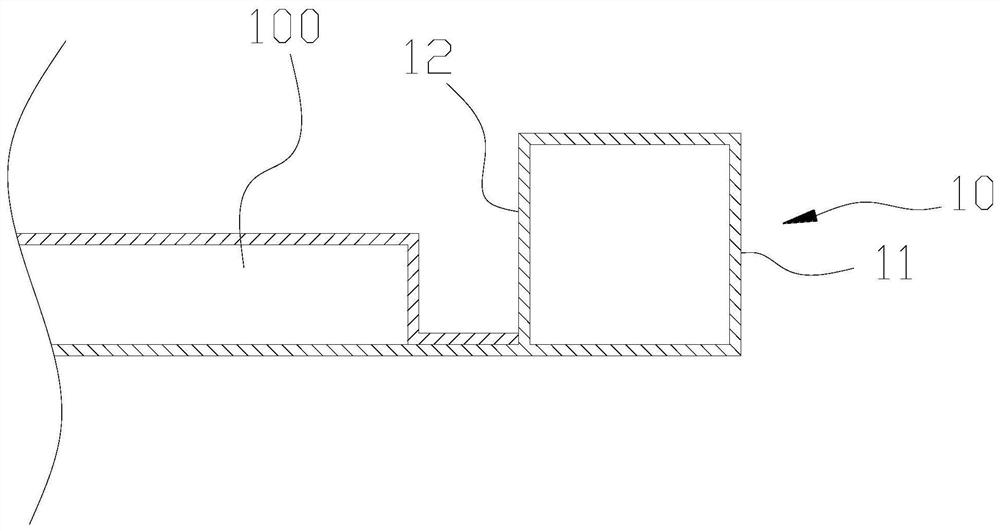

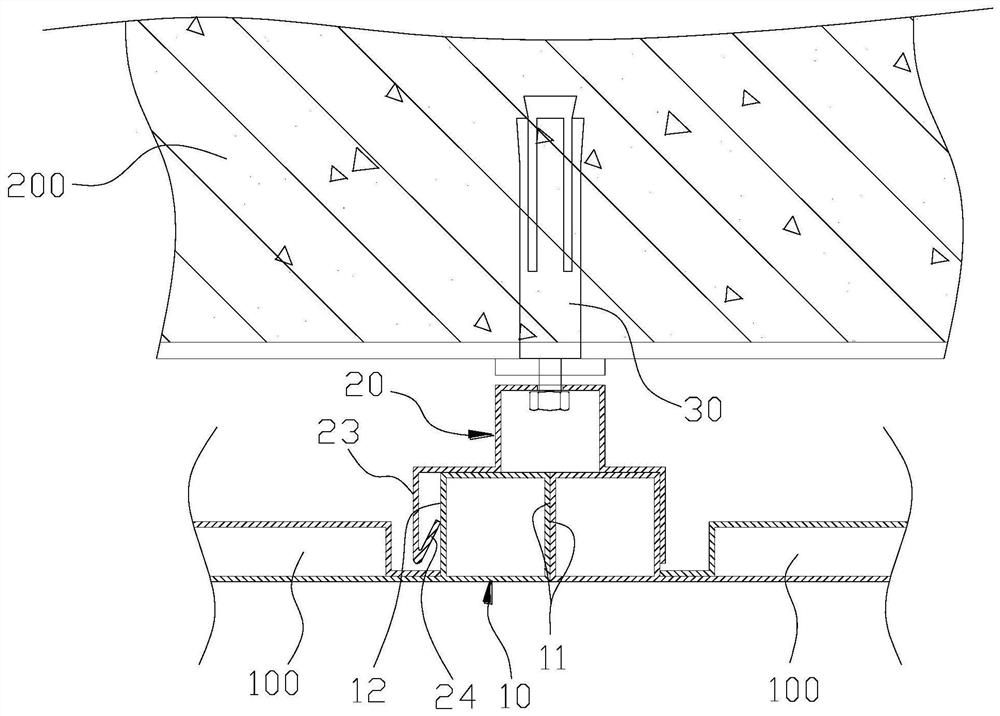

[0064] Such as Figure 1 to Figure 3 As shown, in this embodiment, only one side plate 23 of the second member 20 forms an elastic arm 24, and after the two first members 10 are inserted into the second member 20, the side plate 23 with the elastic arm 24 utilizes the elastic arm 24 Elastic force is applied to one force receiving surface 12 , and the other side is attached to the other force receiving surface 12 .

Embodiment 2

[0066] Such as Figure 4 and Figure 5 As shown, in this embodiment, the two side plates 23 of the second member 20 are bent to form two opposite elastic arms 24, and the two elastic arms 24 jointly define the notch of the slot 21, which makes the two It is more convenient to insert the first member 10 into the second member 20 . After the two first members 10 are inserted into the second member 20 , the two elastic arms 24 apply elastic force to the two force-receiving surfaces 12 respectively.

Embodiment 3

[0068] Such as Figure 6 and Figure 8 As shown, in this embodiment, the elastic arm 24 is bent twice to form a bent section, and the vertex formed by the bent section 241 at the bend has a certain arc, and the vertex slides on the force-bearing surface 12 and has a certain curvature. The force surface 12 exerts elastic force, and the apex with a certain radian will not scratch the force surface 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com