Efficient film laminating machine

A laminating machine, high-efficiency technology, applied in the direction of layered products, lamination devices, lamination, etc., can solve the problems of unstable pasting and inconspicuous pasting effect, and achieve the effect of firm pasting, improved stickiness and easy pasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

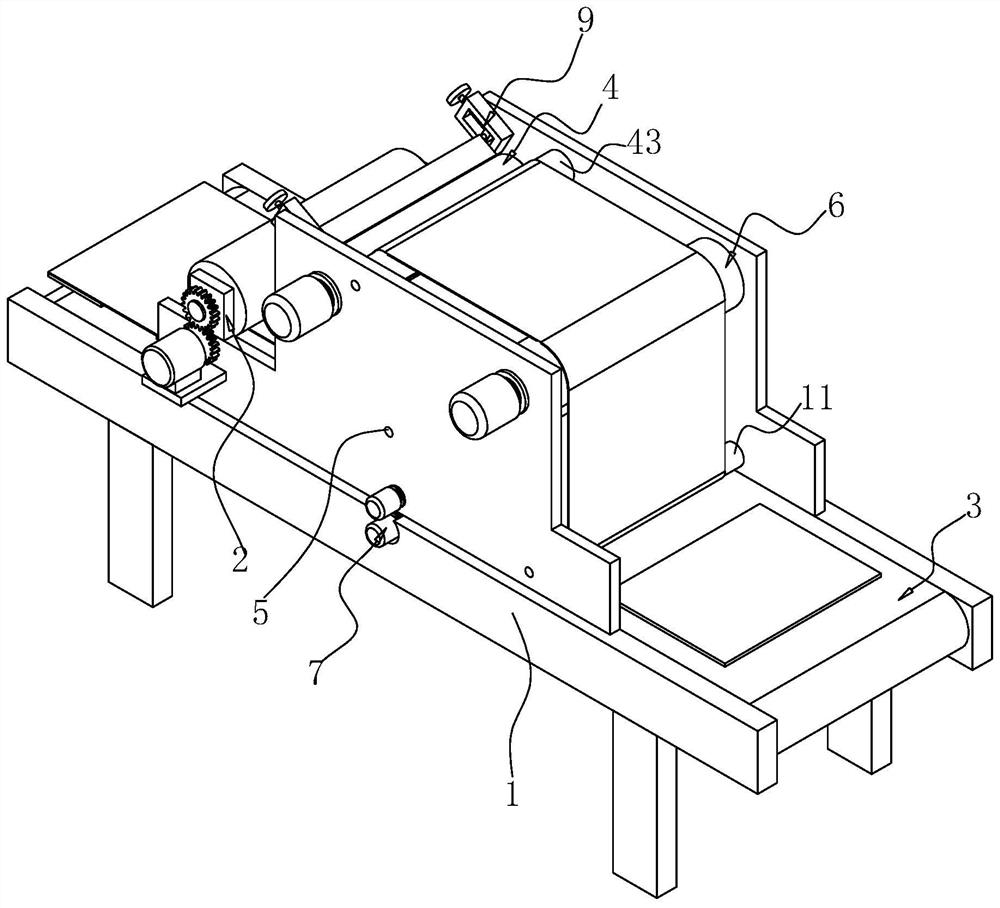

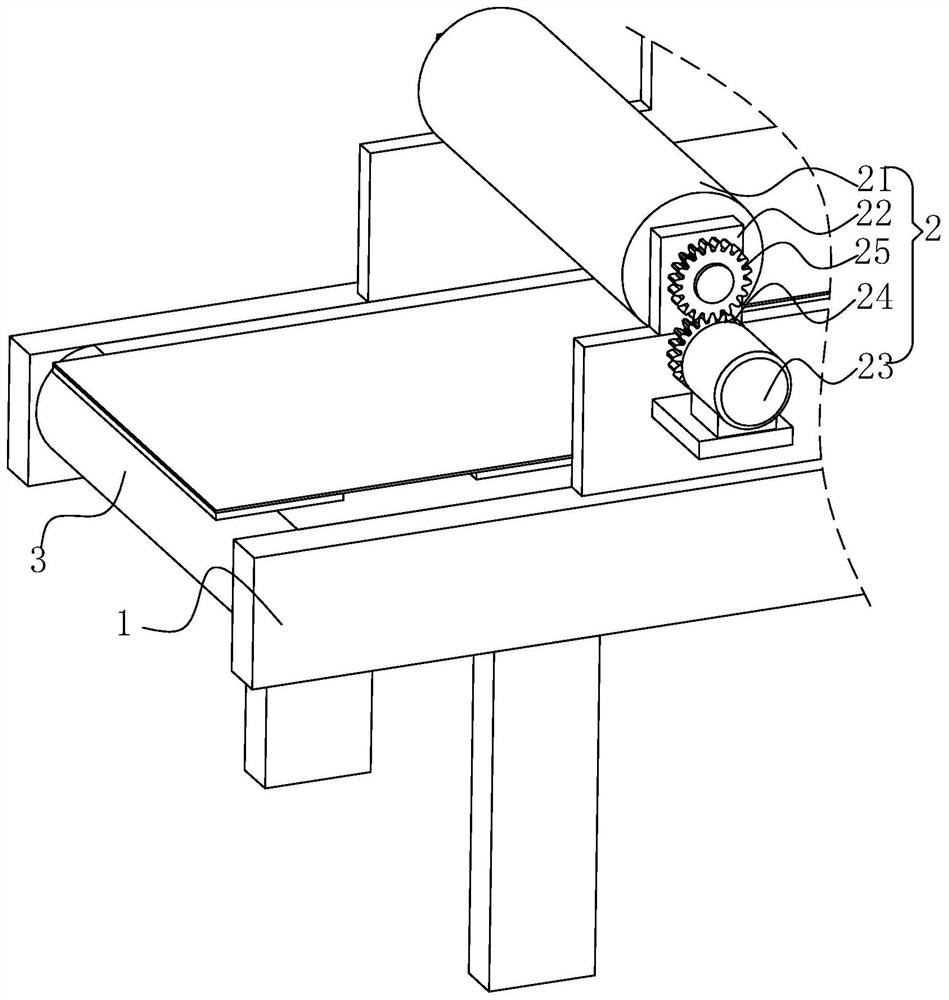

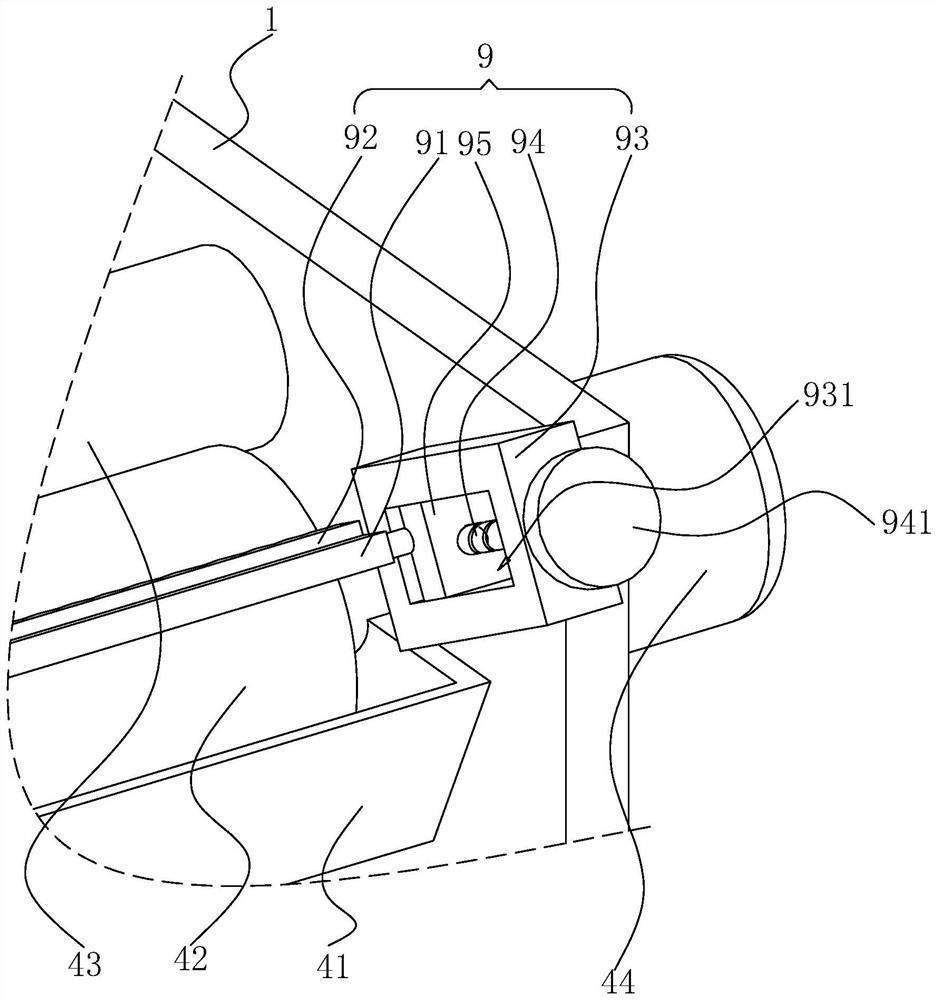

[0036] refer to figure 1, is a high-efficiency laminating machine disclosed in the present invention, including a frame 1 and a conveying assembly 3, and the side of the frame 1 near the conveying end of the conveying assembly 3 is provided with an unwinding assembly 2 that provides a film, and the unwinding assembly 2 is compatible with Above the conveying assembly 3, the side of the unwinding assembly 2 close to the conveying assembly 3 is provided with a gluing assembly 4 for gluing the film, the gluing assembly 4 is located above the unwinding assembly 2, the gluing assembly 4 is connected to the unwind Between the components 2, there is an adjustment roller 5 for guiding and adjusting the film. The two ends of the adjustment roller 5 pass through the frame 1 and are connected to the frame 1 in rotation. The heating assembly 6 for heating the film and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com