An anti-deviation device for wire cutting wire feeding mechanism

A technology of wire feeding mechanism and anti-deviation, which is applied in the direction of accessory devices, manufacturing tools, electrode manufacturing, etc., and can solve problems such as difficulty in adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

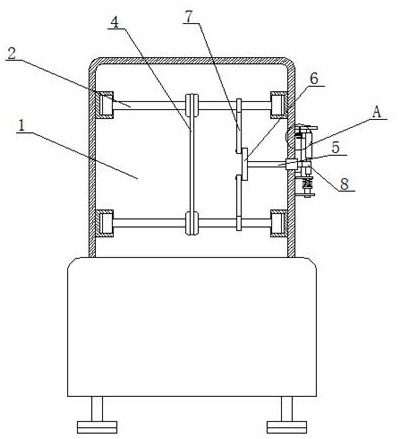

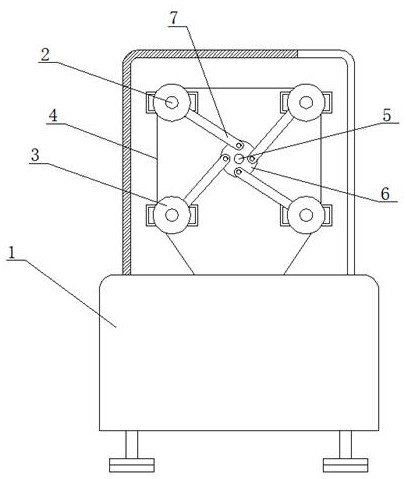

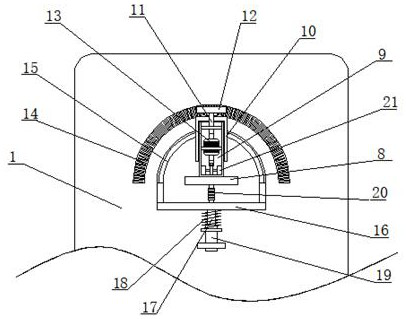

[0027] refer to Figure 1-7 In this embodiment, an anti-deviation device for a wire-cutting wire feeding mechanism is proposed, including a chassis 1, and four support rods 2 are symmetrically slidably connected in the cabinet 1, and the purpose of setting the support rods 2 horizontally is to facilitate the transmission wheel 3 It is convenient to adjust the position of the electrode wire 4, and the transmission wheel 3 is set on the rotation sleeve of the support rod 2, and the same electrode wire 4 is connected to the four transmission wheels 3. On the inner wall of one side of the chassis 1 Rotationally connected with a rotating shaft 5, one end of the rotating shaft 5 is in transmission connection with the four support rods 2, and the other end of the rotating shaft 5 extends to the outside of the cabinet 1 and is fixedly installed with a mounting plate 8. The mounting plate 8 is set to facilitate the installation of the biaxial motor 13. The double-axis motor 13 can accu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com