A device for efficient removal of tobacco inner stems

A shredded tobacco and equipment technology, applied in the field of material selection equipment, can solve the problems of not being able to improve the quality of twig cigarettes, and cannot realize the selection of shredded tobacco materials, and achieve the effect of ideal removal effect and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] First of all, it should be noted that the electrostatic fine separation mechanism in the prior art has difficulties when it is directly applied to cut tobacco sorting. Selection of cut stems. The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the principles of the present invention and facilitate the implementation and improvement of those skilled in the art, but are not intended to limit the scope of the present invention.

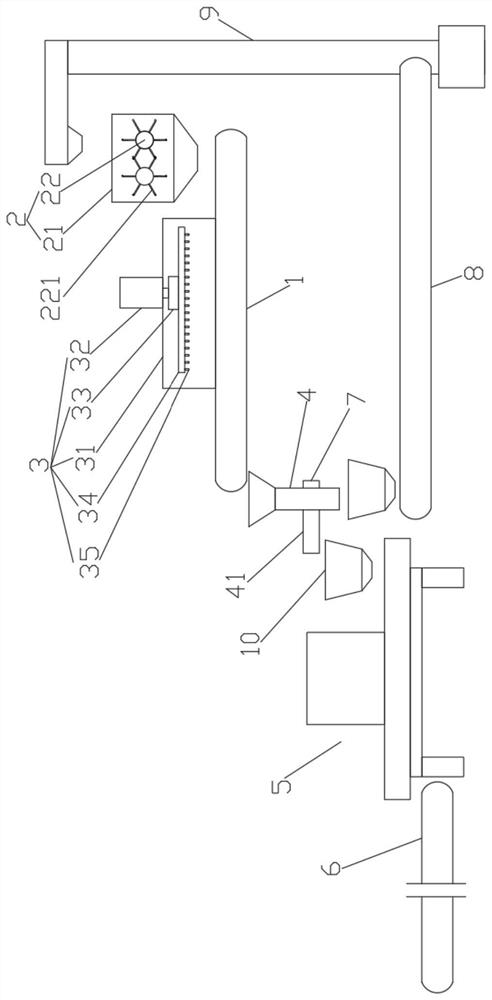

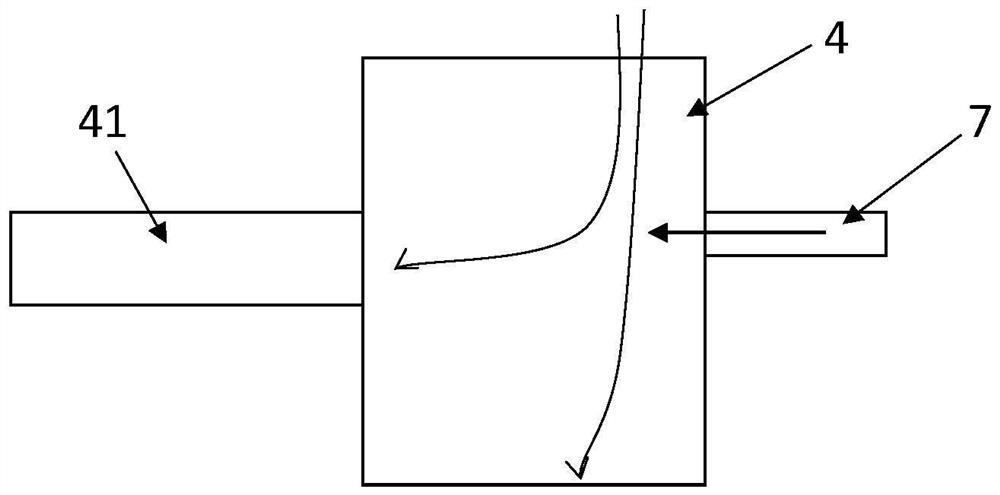

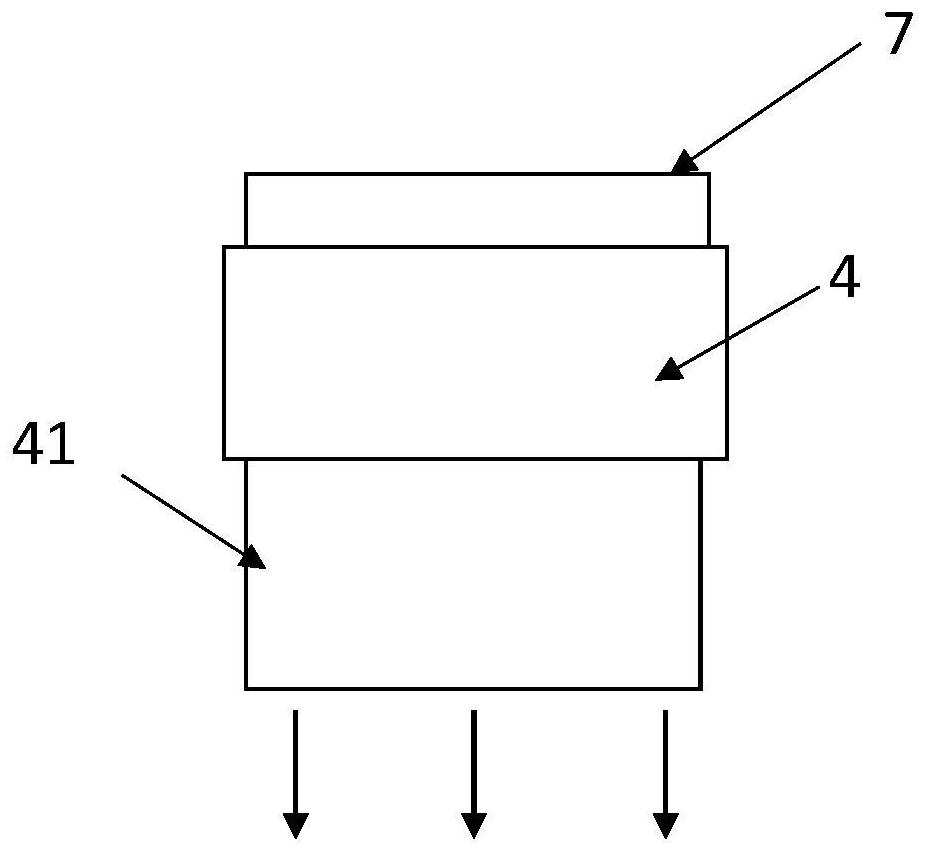

[0030] refer to figure 1 , 2 3, in one embodiment of the present invention, the equipment for efficient removal of cut tobacco stems includes a first conveying line 1, cut stem agglomeration loosening device 2, cut stem flattening mechanism 3, air selection channel 4, electrostatic fine Separation mechanism 5 and second conveying line 6 . Wherein, the cut tobacco to be treated is directly added into the cut stem agglomeration and loosenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com