Cabbage harvester

A harvester and cabbage technology, applied in the field of harvester, can solve the problems of poor applicability harvesting mechanism, easy to damage cabbage, etc., and achieve the effect of improving efficiency, reducing wear and avoiding skew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

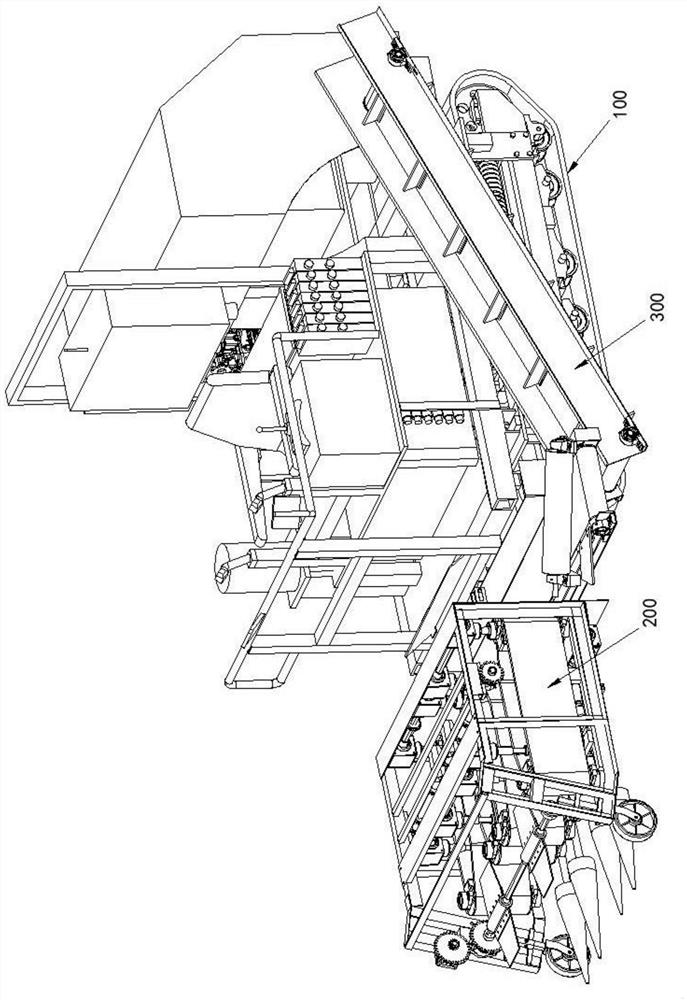

[0031] like figure 1 As shown, the cabbage harvester of this embodiment includes a traveling mechanism 100, a harvesting mechanism 200, a transmission mechanism 300 and a controller;

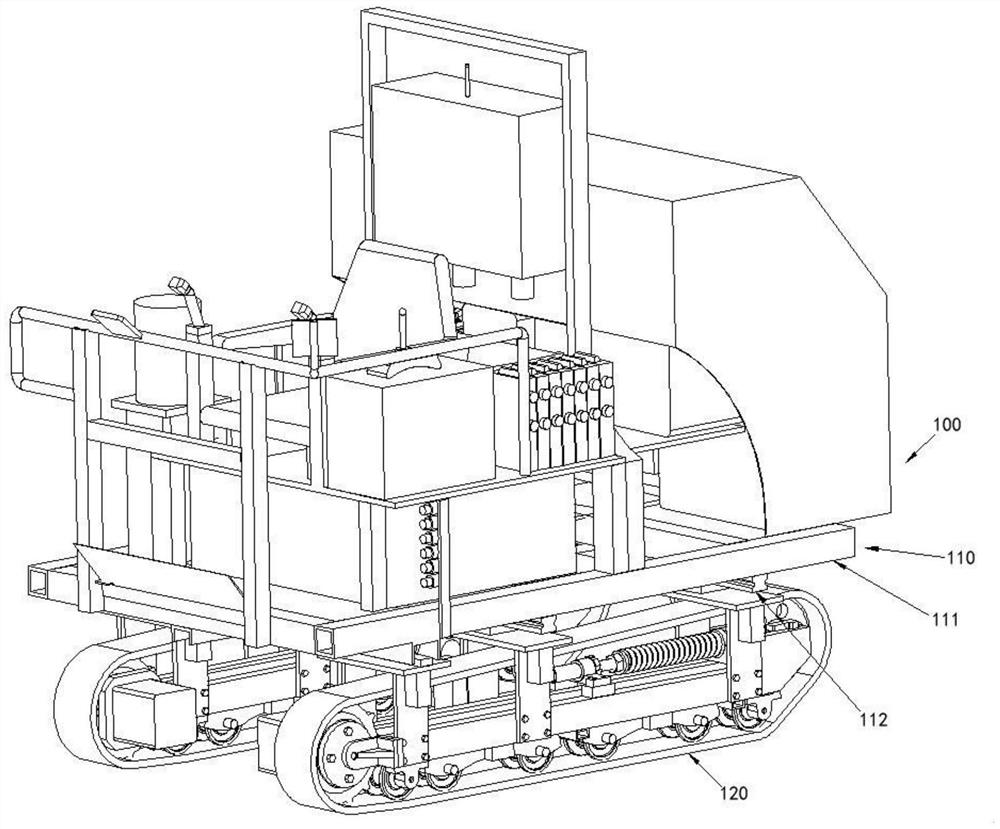

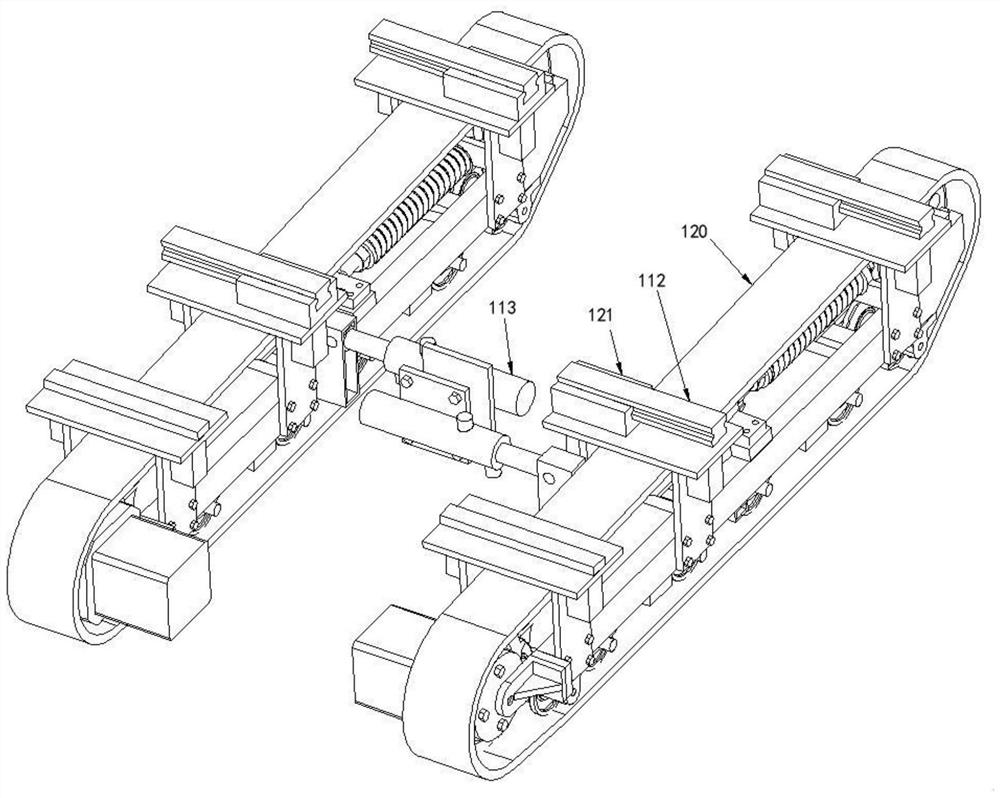

[0032] like figure 2As shown, the traveling mechanism 100 includes a chassis assembly 110, two crawler belt assemblies 120, an internal combustion engine, a first hydraulic pump, a motor and a second hydraulic pump, the chassis assembly 110 includes a chassis frame 111, a slider 112 and a hydraulic cylinder 113, and the chassis frame 111 Used to carry equipment such as cab, internal combustion engine, first hydraulic pump, motor, second hydraulic pump, control system, harvesting mechanism 200 and transmission mechanism 300, slide block 112 and hydraulic cylinder 113 are installed on the bottom of chassis frame 111, such as image 3 As shown, the track assembly 120 is provided with a slide rail 121 perpendicular to the track, the slider 112 is located in the slide rail 121, the number of hydrau...

Embodiment 2

[0042] like Figure 7 As shown, the cabbage harvester of this embodiment is basically the same as that of Embodiment 1, except that the cabbage harvester of this embodiment is provided with an angle sensor 260 and a driving lever 270 on the harvesting platform 210, and the driving lever 270 is rotatable. Installed on the harvesting stand 210, a pair of driving levers 270 is located above a pair of extracting rollers 222, and the angle sensor 260 measures the rotation angle of the driving lever 270 and transmits the measurement result to the controller; when the rotation angle of the pair of driving levers 270 When the difference is greater than the set value, the controller modifies the speeds of the two track assemblies 120 to change the forward direction of the traveling mechanism 100;

[0043] like Figure 7 As shown, before the cabbage 400 enters the extraction roller 222, the two driving levers 270 will be synchronously triggered to rotate. Deviation, this situation is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com