A new energy electric vehicle lithium battery aluminum profile radiator

A technology for electric vehicles and aluminum profiles, which is used in secondary batteries, electrochemical generators, battery pack components, etc. Service life, incapability of new energy electric vehicle lithium battery shock absorption protection, etc., to avoid poor contact, ensure service life, and prevent service life from shortening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

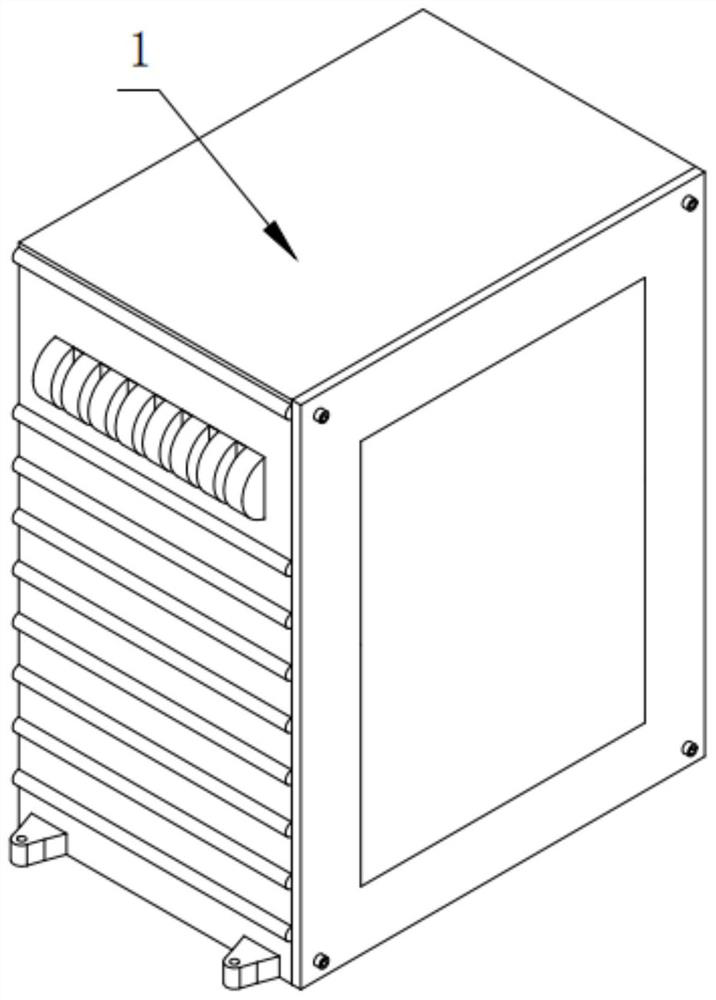

[0040] A new energy electric vehicle lithium battery aluminum profile radiator, such as figure 1 and 7 As shown in -8, it includes: a main structure 1, an assembly mechanism 2 and a heat dissipation mechanism 3.

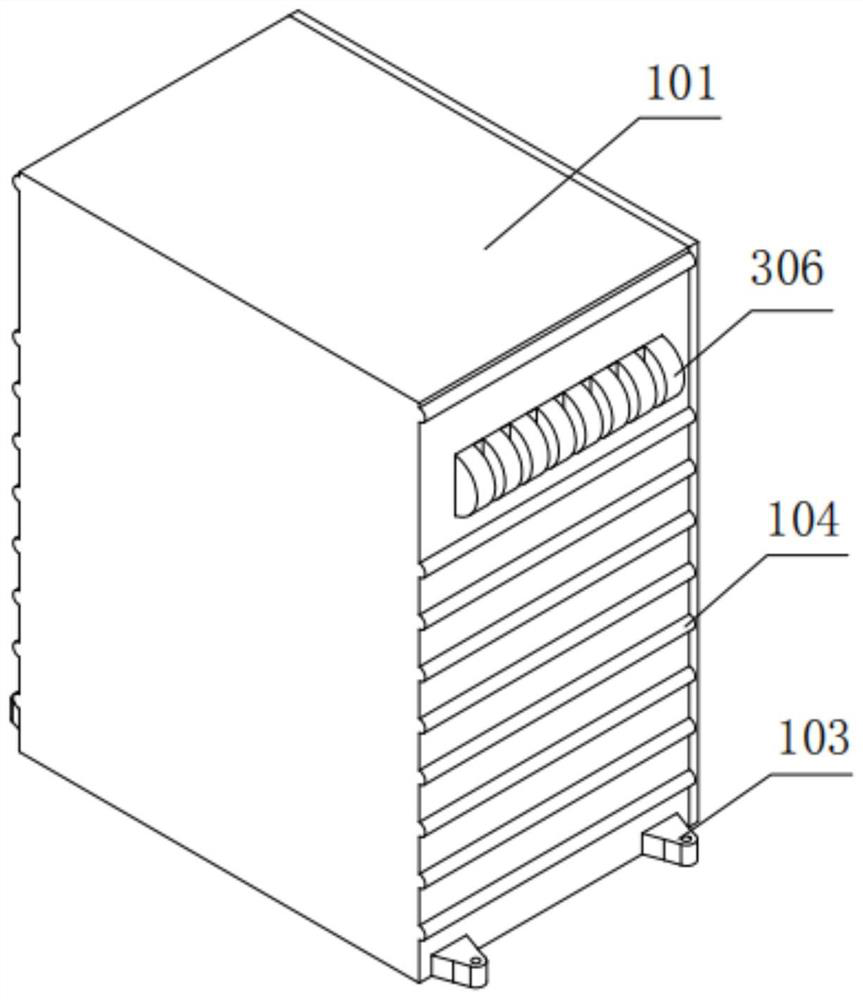

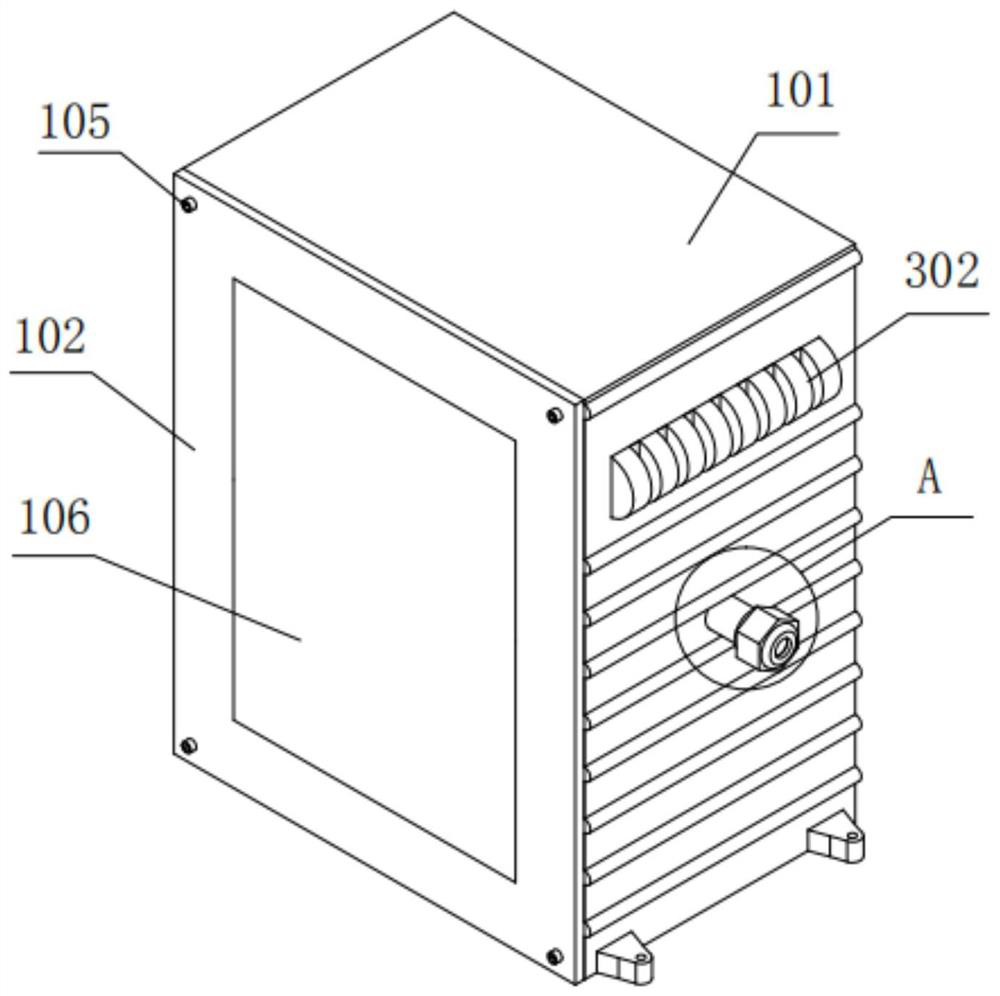

[0041] Among them, such as Figure 1-3 As shown, the main structure 1 includes an aluminum profile shell 101 and an aluminum profile side cover 102, one side of the aluminum profile shell 101 is an open structure, and the aluminum profile side cover 102 is fixed and installed on the aluminum profile shell 101 with an open structure by screws 105 On one side, a sealed space is formed between the aluminum profile side cover 102 and the aluminum profile shell 101;

[0042] Among them, such as figure 1 and 7 As shown in -10, the assembly mechanism 2 includes an assembly plate 201 and an assembly box 202. The assembly plate 201 is fixedly installed on the upper part of the inner bottom wall of the aluminum profile shell 101 through four sets of shock absorbers 203, an...

Embodiment 2

[0051] Such as Figure 3-6 As shown in and 10, the difference between this embodiment and Embodiment 1 is that a threading hole 111 is provided on the side wall of the aluminum profile housing 101, and the outer surface of the side wall provided with the threading hole 111 is fixed on the aluminum profile housing 101. A threading pipe 107 is installed, and the threading pipe 107 is coaxially arranged with the threading hole 111, and the outer end of the threading pipe 107 away from the aluminum profile shell 101 is screwed with a locking sleeve 108, and the inside of the locking sleeve 108 and the threading pipe 107 are far away from the aluminum profile An annular sealing rubber sleeve 109 is installed between one end of the housing 101 . The inner portion of the annular sealing rubber sleeve 109 has a figure-eight cavity 110 , and the inner ring surface of the annular sealing rubber sleeve 109 is a semicircular structure.

[0052] By adopting the above-mentioned technical sc...

Embodiment 3

[0054] Such as Figure 11 As shown, the difference between this embodiment and Embodiment 2 is that the rubber block 2033 is uniformly provided with a number of waist-shaped through holes penetrating through its side, and both ends of the rubber block 2033 are provided with half holes penetrating through its side. Circular groove.

[0055] By adopting the above-mentioned technical solution, the rubber block 2033 has better elastic deformation performance under the cooperation of the waist-shaped through hole and the semicircular groove, so that the shock-absorbing performance of the shock-absorbing member 203 is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com