In-cylinder direct injection solenoid valve injector

A technology of in-cylinder direct injection and solenoid valve, which is applied in fuel injection devices, machines/engines, charging systems, etc., and can solve the problem of large average particle size of fuel atomized particles, excessive injection hole diameter and hole depth ratio, and steel ball grinding. Problems such as processing difficulties in flattening, etc., to achieve high product quality, reduce engine fuel consumption, and stable and reliable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

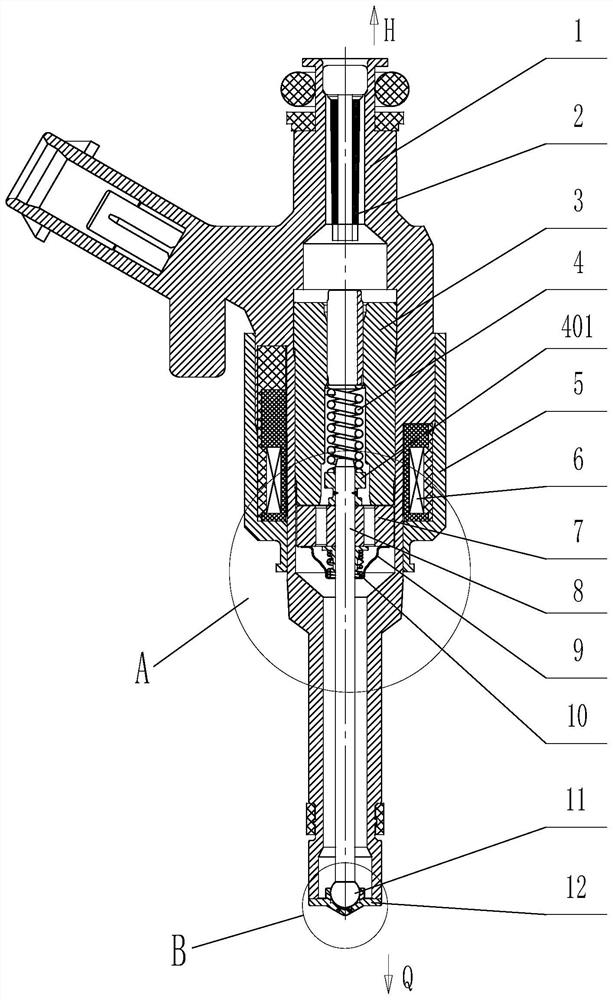

[0034] figure 1 Shown in is an in-cylinder direct-injection electromagnetic valve injector, which includes a casing 1, a filter screen 2, a main shaft 3, a return spring 4, a magnetic sleeve 5, a coil 6, a valve core 7, and a valve core connecting rod 8 , buffer spring sleeve 9, buffer spring 10, steel ball 11, valve seat 12, wherein:

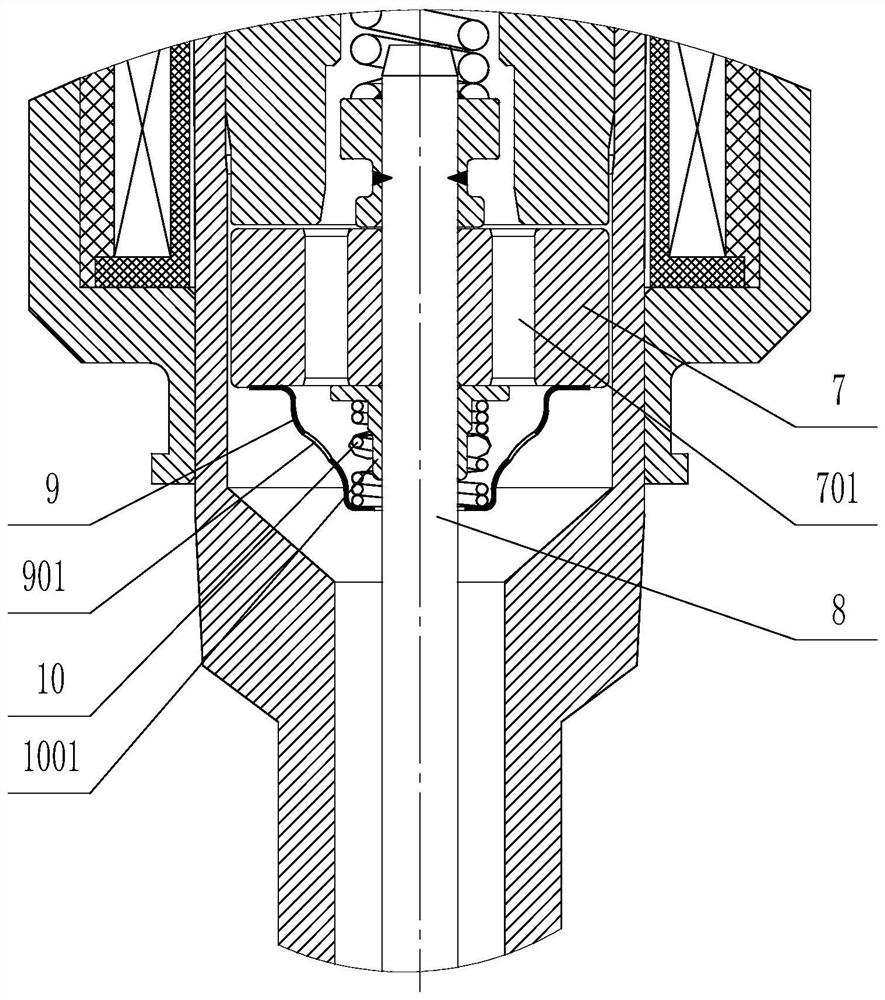

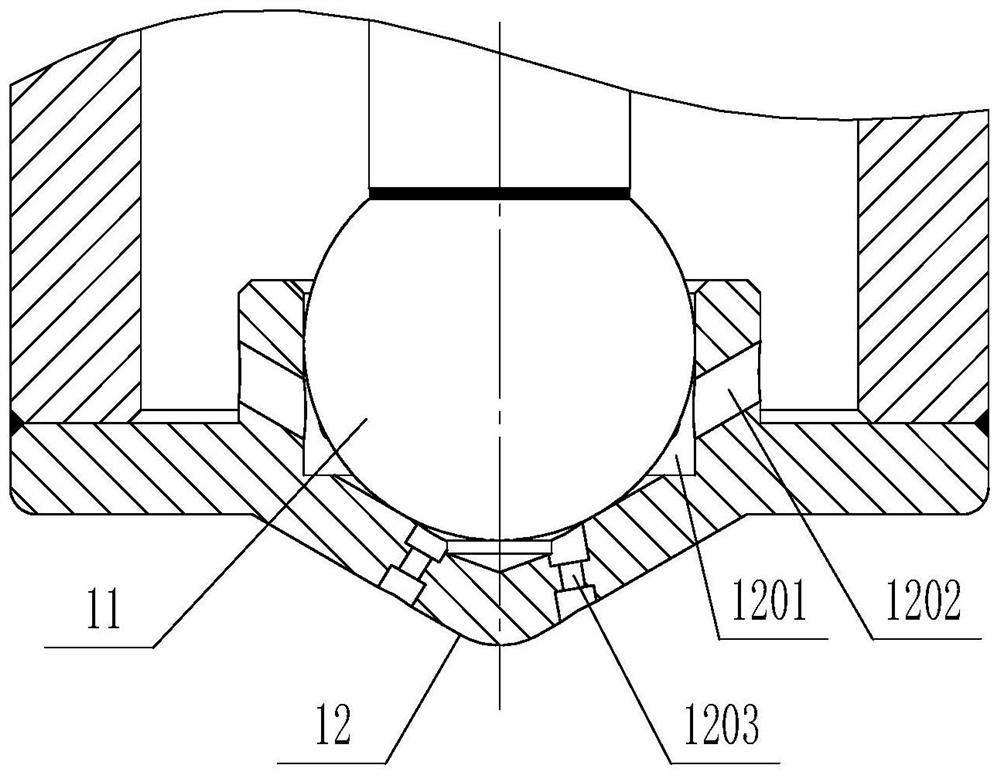

[0035] The filter screen 2 and the main shaft 3 are sequentially installed in the housing 1, the return spring 4 is installed in the main shaft 3, the magnetic sleeve 5 is installed outside the housing 1, and the coil 6 is installed between the magnetic sleeve 5 and the housing 1. coil holder. The middle part of the valve core 7 is connected to the valve core connecting rod 8, and the valve core 7 is provided with a steady flow hole I701 in the axial direction around the valve core connecting rod 8 (see figure 2 ); the rear end of the spool connecting rod 8 is connected to the installation block 401 of the return spring 4 ; the front end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com